Device and method for mechanical sealing evaluation of cement ring when large fracturing is performed

A mechanical seal and cement sheath technology, which is applied in the testing of mechanical components, liquid tightness measurement using liquid/vacuum degree, and measuring devices, etc. It can solve the problems of inability to compare the performance of cement sheaths and quantitative analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

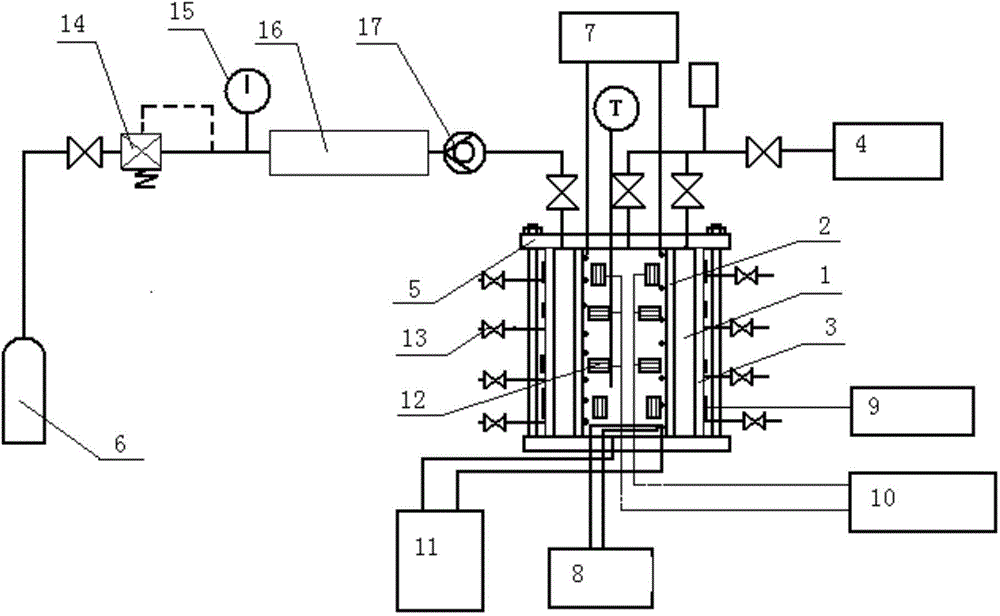

Method used

Image

Examples

example 1

[0043] The test temperature was slowly raised from room temperature to 85°C within 24 hours, 2MPa gas was injected into the bottom annulus to keep the gas stable, and the circumferential stress of the cement annulus was measured at 0.52MPa. The temperature rose slowly to 120°C within 48 hours, the pressure at the top of the annulus was detected to be 1.9MPa, the peak value of the circumferential stress of the cement annulus was 2.3MPa, and the seal of the cement annulus failed. Confirm that the cement sheath seal fails due to thermal expansion, and record the relevant data.

example 2

[0045] The test temperature is 23°C, and the gas pressure is 2MPa injected into the bottom of the cement sheath. Pressurize the inner cylinder of the annular space model through the liquid booster pump, and the boosting rate is 10MPa / 10min. When the internal pressure is 30MPa, the circumferential stress of the cement sheath is measured to be 1.4MPa, and the top pressure is 0MPa, and no sound signal is detected by the acoustic wave detection instrument. When the internal pressure of the model is 61.5MPa, the measured circumferential stress drops from 2.3MPa to 0MPa, the bubble detector has an obvious peak, and the sound wave detects an obvious peak, and the pressure at the top of the model is 1.8MPa. It was confirmed that the internal pressure overload caused the tensile failure of the cement sheath, resulting in the failure of the cement sheath seal.

Embodiment 3

[0047] The experimental temperature rises slowly from 23°C, and the maximum temperature does not exceed 85°C. The bottom of the cement sheath is injected with a gas pressure of 2MPa, and the inner cylinder of the annulus model is pressurized through a liquid booster pump, and the experimental pressure boost rate is 10MPa / 10min. When the internal pressure is 30MPa, the circumferential stress of the cement sheath is measured to be 1.7MPa, the top pressure is 0MPa, and no sound signal is detected by the acoustic wave detection instrument. When the internal pressure of the model is 55MPa, the measured circumferential stress drops from 2.3MPa to 0MPa, the bubble detector has an obvious peak, and the sound wave detects an obvious peak, and the pressure at the top of the model is 1.8MPa.

[0048] After comparing the data of the above three examples with the cement sheath that has not been tested, it can be seen that the change of temperature and pressure leads to the sealing failure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com