Copper formate catalyst, and preparation method and applications thereof

A catalyst, the technology of copper formate, which is applied in the field of preparation of copper formate catalyst, can solve the problem of low activity and achieve the effect of simple preparation method, good catalytic activity and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

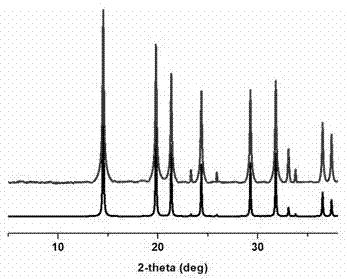

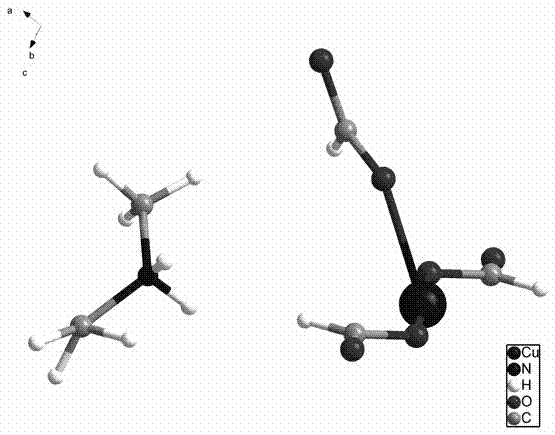

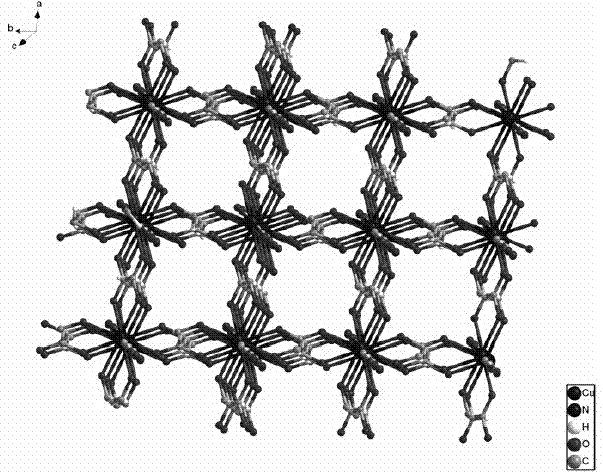

Embodiment 1

[0028] Example 1: Compound CH 3 NH 2 Cu(HCOO) 3 Preparation: Add formic acid (2mmol), copper acetate (1mmol) and 200mmol DMF in sequence in a 25mL clean reaction kettle, stir vigorously for 30min, heat and react at 110°C for 36h, cool and filter to obtain block single crystal. The yield is about 76%.

Embodiment 2

[0029] Example 2: Compound CH 3 NH 2 Cu(HCOO) 3 Preparation: Add formic acid (1mmol), copper acetate (1mmol) and 300mmol DMF in sequence in a 25mL clean reaction kettle, stir vigorously for 30min, heat and react at 110°C for 36h, cool and filter to obtain block single crystal. The yield is about 53%.

Embodiment 3

[0030] Example 3: Compound CH 3 NH 2 Cu(HCOO) 3 Preparation: Add formic acid (2mmol), copper acetate (1mmol) and 300mmol DMF in sequence in a 25mL clean reaction kettle, stir vigorously for 30min, heat and react at 110°C for 48h, cool and filter to obtain block single crystal. The yield is about 74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com