Support platform for assembly and disassembly of diesel engine crankshaft shock absorber

A technology of crankshaft shock absorber and supporting platform, which is applied in the directions of crankshaft, shaft, shaft and bearing, etc., can solve the problems of scratches on the inner hole of the crankshaft and shock absorber, precise positioning of difficult pin holes, complicated operation process, etc., to avoid The effect of hoisting, high installation efficiency and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

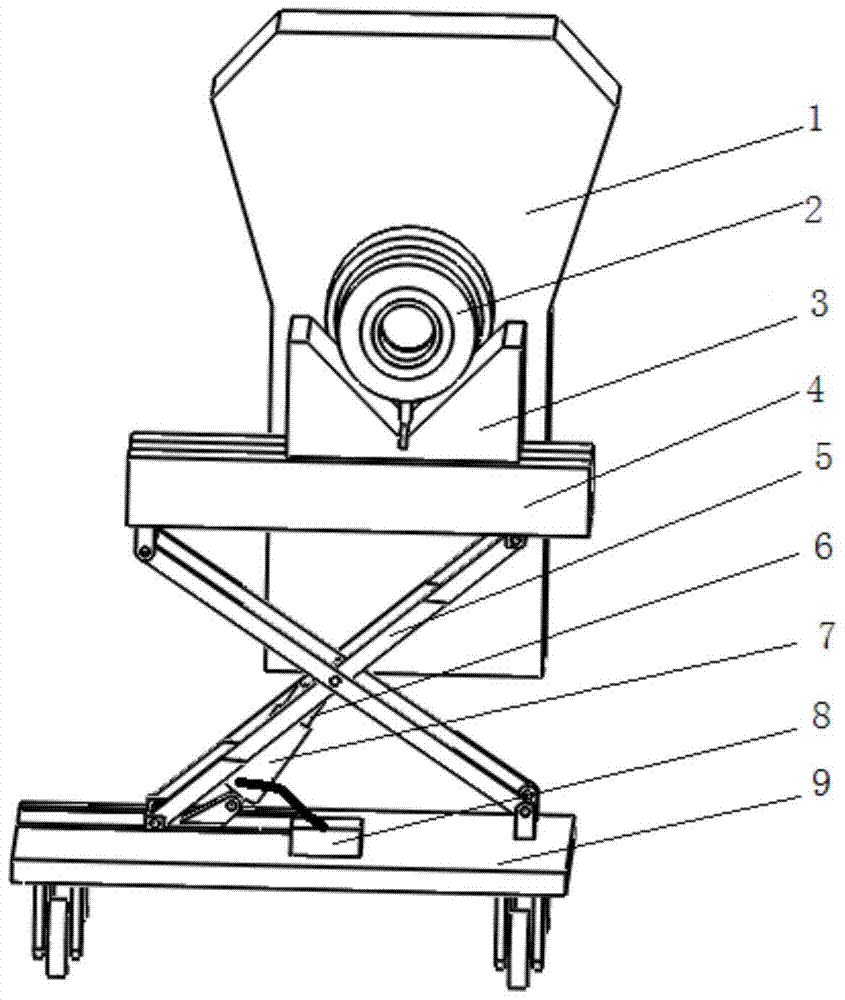

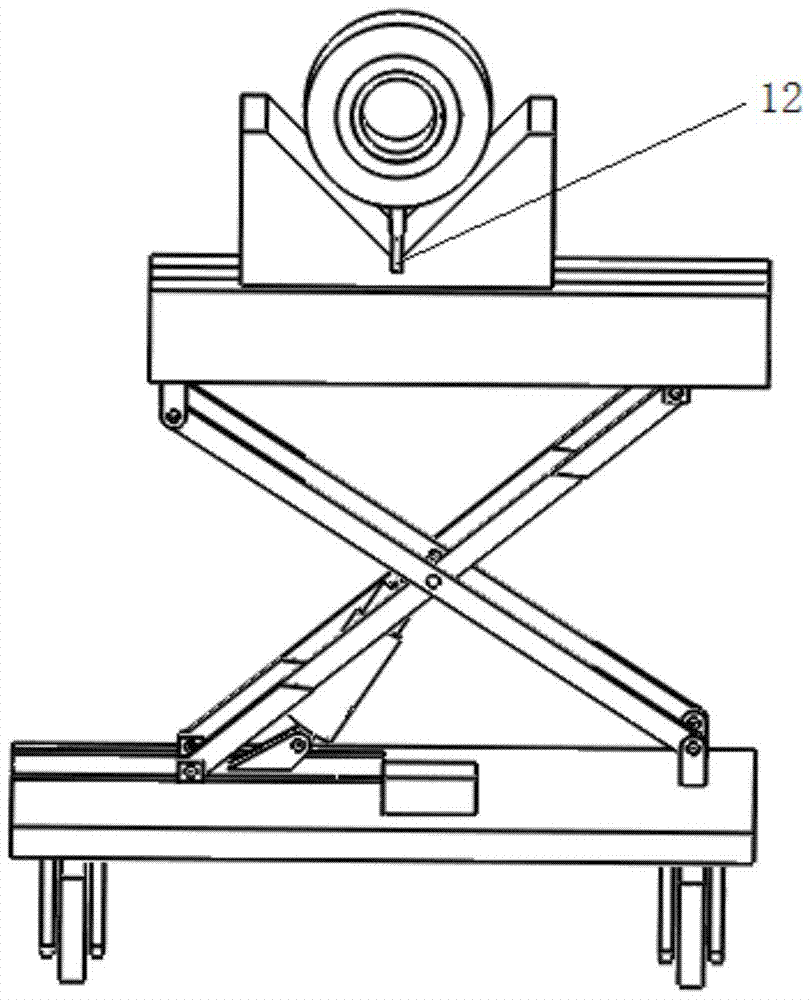

[0019] Such as figure 1 As shown, the supporting platform for assembly and disassembly of the diesel engine crankshaft shock absorber of the present invention includes an axial V-shaped groove 3, a horizontal moving platform 4, a hydraulic lifting device 5, and a moving base 9 with a locking function.

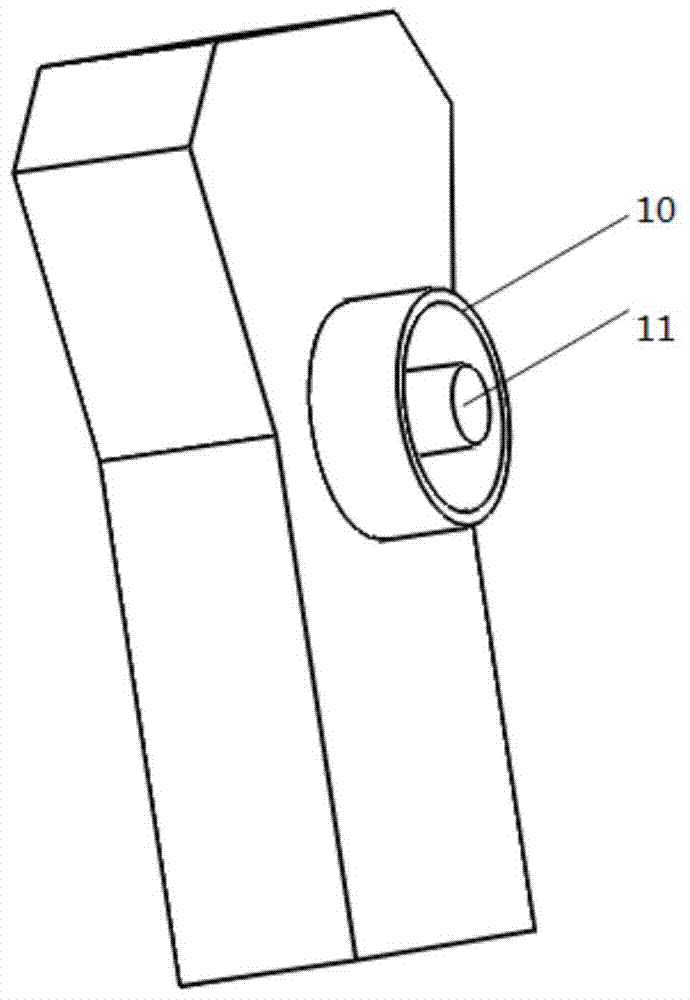

[0020] Such as figure 1 and image 3 As shown, the axial V-shaped groove 3 is used to support and fix the shock absorber 2 . The size of the axial V-shaped groove 3 is designed according to the structural size of the shock absorber 2, and three sizes of axial V-shaped grooves 3 are designed, which can adapt to the installation of different types of shock absorbers 2. The first slider at the lower end of the axial V-shaped groove is embedded in the first chute of the horizontal moving platform, and through the cooperation of the smooth surface, the shock absorber can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com