System for efficiently removing suspended matters in wastewater produced during magnesium desulfurization

A technology for wastewater suspended solids and magnesium desulfurization, which is applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., and can solve problems such as failure to meet discharge standards, easy scaling of impurities and clogging of evaporators and pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

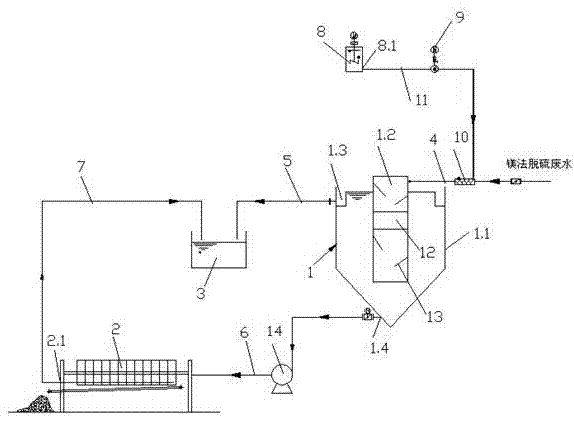

[0011] Embodiment 1: a system for efficiently removing suspended solids from magnesium desulfurization wastewater, comprising a cyclone clarifier 1, a plate and frame filter press 2 and a slurry clarifier 3, the cyclone clarifier 1 includes a housing 1.1 and a housing 1.1 The central cyclone cylinder 1.2 and the settler, the central cyclone cylinder 1.2 is tangentially connected to the magnesium removal method desulfurization wastewater inlet pipe 4, the top overflow port 1.3 of the shell 1.1 is connected to the slurry clarification tank 3 through the overflow pipe 5, and the cyclone clarification device 1 Shell 1.1 Bottom sewage outlet 1.4 is connected to the plate and frame filter press 2 through the sewage pipeline 6, and the liquid outlet 2.1 of the plate and frame filter press is connected to the slurry clarifier 3 through the liquid outlet pipeline 7. The sewage pipeline 6 is provided with Sludge lift pump 14.

Embodiment 2

[0012] Embodiment 2: with reference to embodiment 1, be provided with dosing system in addition, described dosing system comprises drug dissolving device 8, dosing metering pump 9 and pipeline mixer 10, and dissolving device 8 mixed solution outlet 8.1 passes through dosing pipeline 11 is connected to the pipeline mixer 10 arranged on the water inlet pipe 4, and the medicine adding metering pump 9 is arranged on the medicine adding pipeline 11.

Embodiment 3

[0013] Embodiment 3, referring to Embodiment 1 or 2, a packing layer 12 is arranged in the central swirl cylinder 1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com