Heat storage and preservationhydrogel finishing agent for textile products and preparation method of heat storage and preservationhydrogel finishing agent

A hydrogel and textile technology, applied in the direction of plant fibers, etc., can solve the problems such as the technical disclosure of heat storage and thermal insulation hydrogel finishing agent, the falling off of phase change materials, loss of temperature regulation performance, etc., and achieve easy acquisition and operation. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

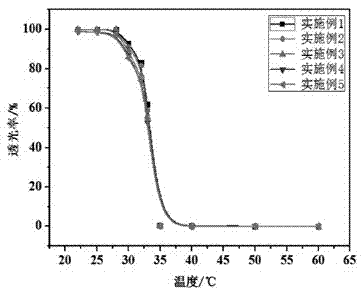

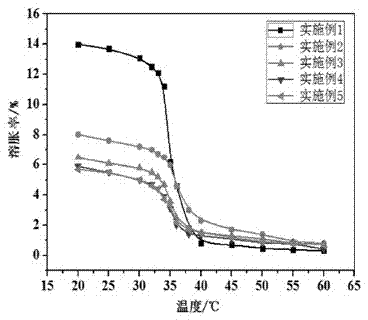

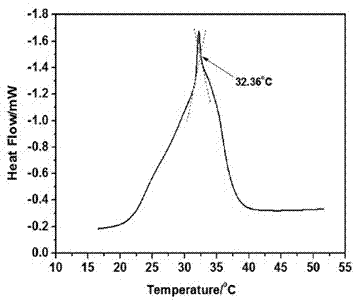

Embodiment 1

[0033] (1) Mix and dissolve 100 parts of N-isopropylacrylamide, 25 parts of chitosan and 1 part of N,N-methylenebisacrylamide at room temperature;

[0034] (2) Add potassium persulfate (K 2 S 2 o 8 ) 1 part and sodium bisulfite (NaHSO 3 ) 1.2 parts, stirred evenly, and reacted at room temperature for 24 hours to obtain a hydrogel;

[0035] (3) Dry and grind the hydrogel obtained above at 60° C. to obtain hydrogel powder.

Embodiment 2

[0037] (1) Mix and dissolve 100 parts of N-isopropylacrylamide, 50 parts of chitosan and 1.5 parts of N,N-methylenebisacrylamide at room temperature;

[0038] (2) Add potassium persulfate (K 2 S 2 o 8 ) 1.5 parts and sodium bisulfite (NaHSO 3 ) 1.8 parts, stirred evenly, and reacted at room temperature for 24 hours to obtain a hydrogel;

[0039] (3) Dry and grind the hydrogel obtained above at 65° C. to obtain hydrogel powder.

Embodiment 3

[0041] (1) Mix and dissolve 100 parts of N-isopropylacrylamide, 75 parts of chitosan and 2 parts of N,N-methylenebisacrylamide at room temperature;

[0042] (2) Add potassium persulfate (K 2 S 2 o 8 ) 1.8 parts and sodium bisulfite (NaHSO 3 ) 2.2 parts, stirred evenly, and reacted at room temperature for 24 hours to obtain a hydrogel;

[0043] (3) Dry and grind the hydrogel obtained above at 70° C. to obtain hydrogel powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com