No-trestle water bridge pile foundation and bearing platform construction method and cofferdam thereof

A construction method and technology for cofferdams, which are applied in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as a large amount of steel and labor costs, affect construction efficiency, and prolong construction period, and achieve a compact and orderly construction process. The effect of building and dismantling time and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following non-limiting examples illustrate the invention.

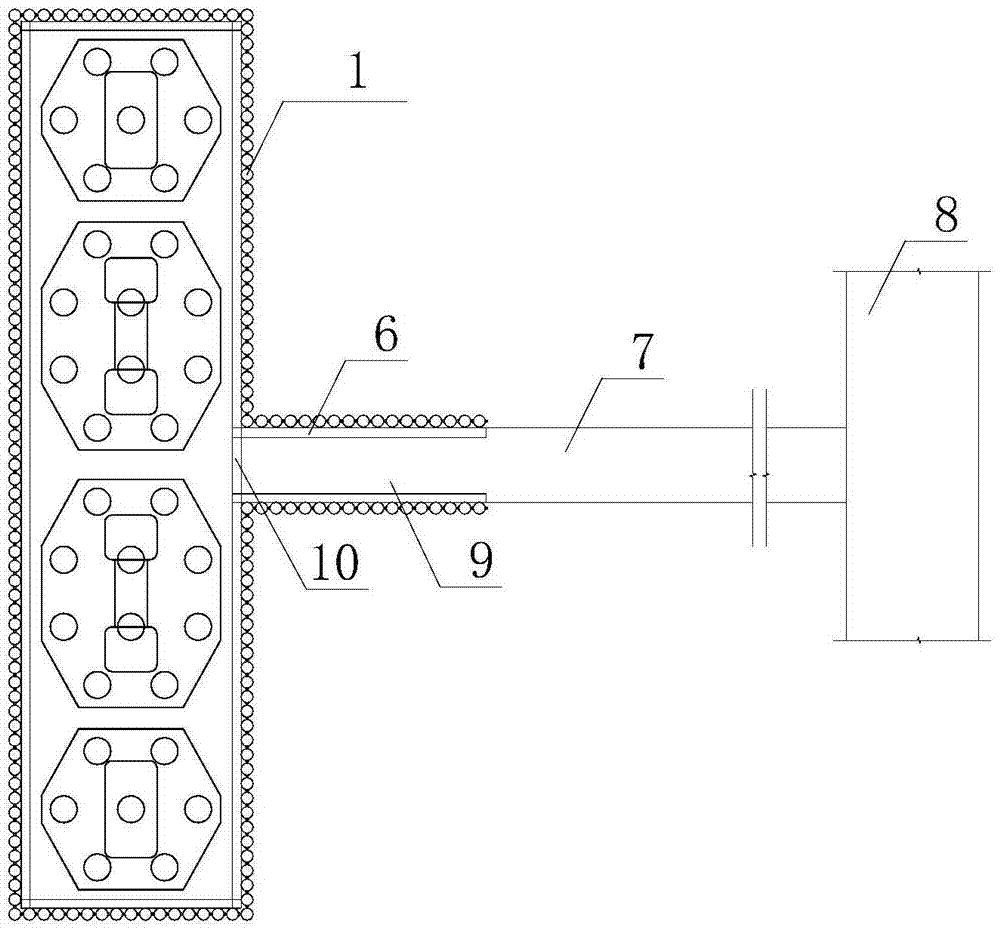

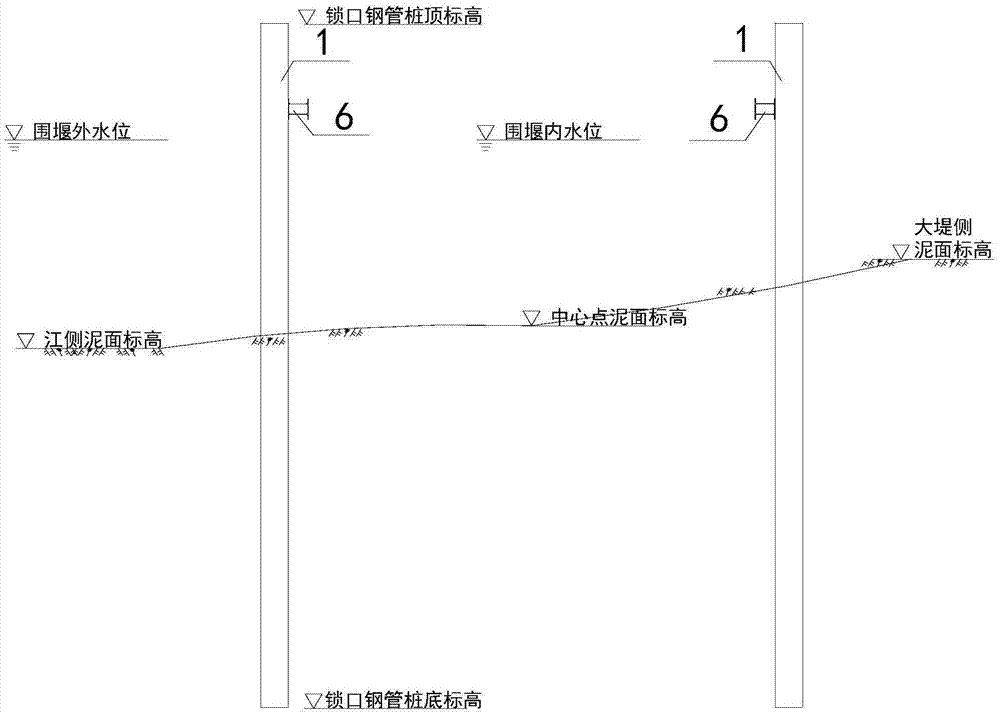

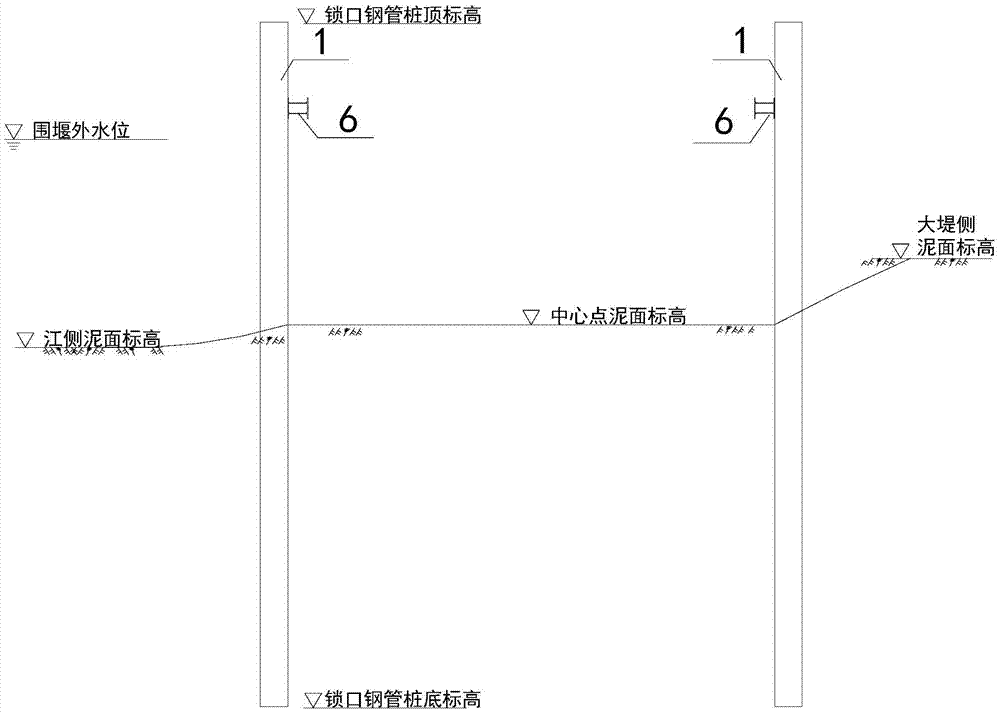

[0038] refer to figure 1 As shown, a kind of cofferdam for construction of bridge pile foundations and caps on water without a trestle includes a cofferdam surrounded by locking steel pipe piles 1 and purlins 6, wherein the locking steel pipe piles 1 are Large flexural modulus and strong deformation resistance, suitable for water retaining structures of open cofferdams. There is no brace 3 inside the cofferdam, and an opening structure is provided on the side of the cofferdam. The opening structure includes An opening 10 on the side, and a passageway 9 connected to the opening 10 provided at the opening 10, the passageway 9 is also composed of locking steel pipe piles 1 and purlins 6, and the construction access road extending from the bank levee 8 7 extends through the passageway 9 up to the opening 10 of the cofferdam. The opening structure can ensure that the drilling rig and some lifting equipment can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com