Hydrodechlorination catalyst and application thereof in preparation of chlorotrifluoroethylene

A hydrodechlorination and catalyst technology, which is used in the preparation of dehalogenation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., to achieve the effect of good stability, moderate activity and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

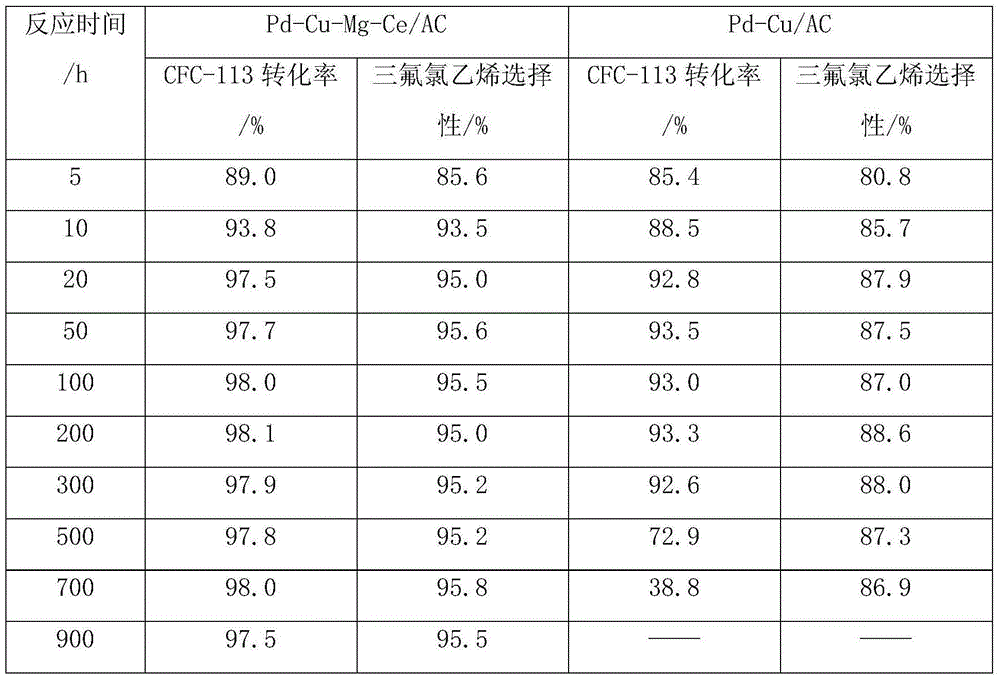

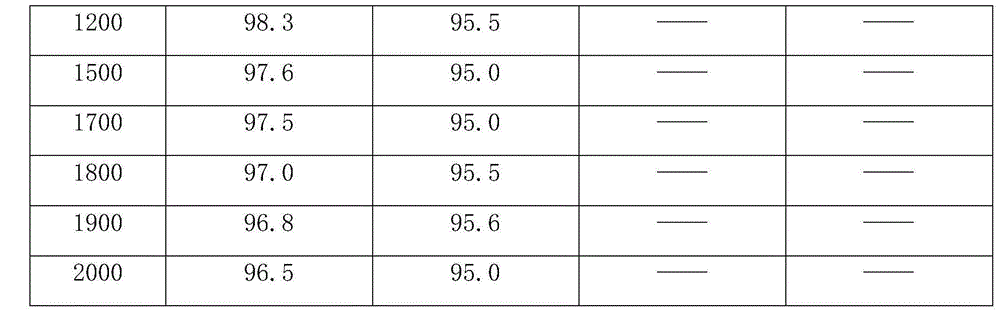

Image

Examples

Embodiment 1

[0030] Embodiment 1Pd-Cu-Mg / AC catalyst preparation

[0031] Weigh 3.8gCu(NO 3 ) 2 ·3H 2 O and 1.7gMg(NO 3 ) 2 ·6H 2 O was added to 6.0ml of palladium source solution (concentration: 0.033gPd / ml), and 80.0ml of distilled water was added to dilute evenly. Take 20g of high-quality activated carbon pretreated with 5% nitric acid, add the above mixed impregnation solution, impregnate for more than 2h, and then dry at 110°C 4h, the Pd-Cu-Mg / AC catalyst was obtained.

Embodiment 2

[0032] Embodiment 2Pd-Cu-Ba / AC catalyst preparation

[0033] Weigh 3.0gCu(NO 3 ) 2 ·3H 2 O with 0.2gBa(NO 3 ) 2 , add 6.0ml of palladium source solution (concentration is 0.033gPd / ml), and add 80.0ml of distilled water to dilute evenly, take 20g of high-quality activated carbon pretreated with 5% nitric acid, add the above mixed impregnation solution, impregnate for more than 2h, and then dry at 110°C After 4h, the Pd-Cu-Ba / AC catalyst was obtained.

Embodiment 3

[0034] Embodiment 3Pd-Cu-Sm / AC catalyst preparation

[0035] Weigh 2.3gCu(NO 3 ) 2 ·3H 2 O and 0.13gSm(NO 3 ) 3 , 4.85ml of palladium source solution (concentration: 0.033gPd / ml), and add 80.0ml of distilled water to dilute evenly, take 20g of high-quality activated carbon pretreated with 5% nitric acid, add the above mixed impregnation solution, impregnate for more than 2h, and then dry at 110°C for 4h , that is, a Pd-Cu-Sm / AC catalyst is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com