Method and system for processing aluminum chlorate class ionic liquid dead catalysts

An ionic liquid and waste catalyst technology, which is applied in the petrochemical field, can solve the problems such as the unsuitability of ionic liquid waste catalyst treatment, and achieve the effects of promoting industrialization promotion, increasing pollution source emissions, and reducing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

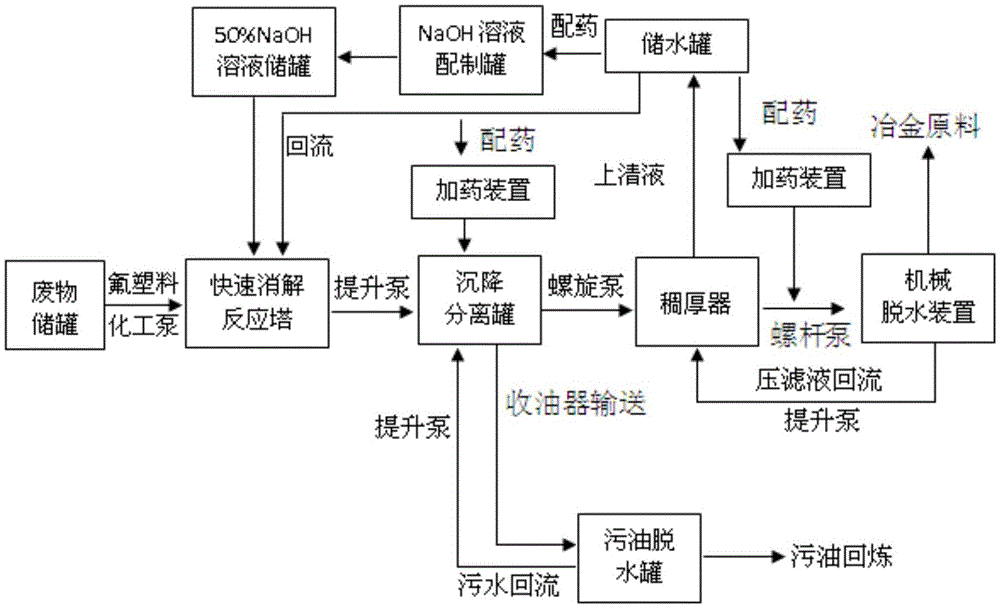

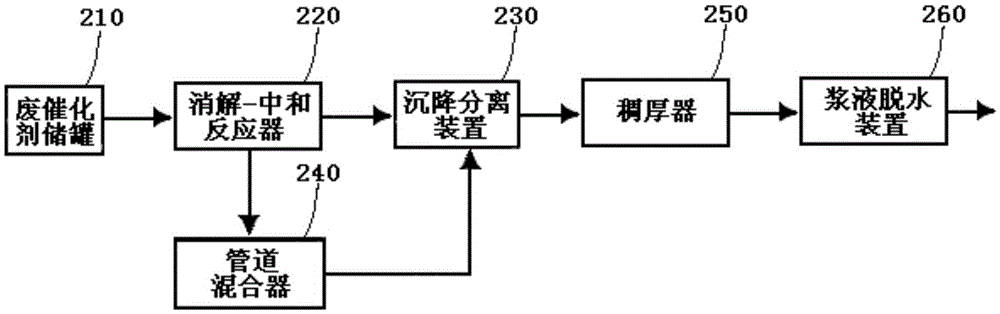

[0039] Embodiments of the present invention provide a method for treating spent chloroaluminate-based ionic liquid catalysts, comprising the following steps:

[0040] The spent chloroaluminate-based ionic liquid catalyst is digested-neutralized with an alkaline solution until the system is neutral to weakly alkaline, and a three-phase mixture consisting of water phase / acid-soluble oil phase / floc is obtained;

[0041] The three-phase mixture is fully mixed with the organic coagulant and separated by sedimentation, and the acid-soluble oil phase of the upper layer and the floc phase of the bottom layer are respectively collected;

[0042] Transfer the floc phase to a thickener for concentration to form a concentrated slurry with a water content of 50-60wt%, part of the concentrated and precipitated aqueous solution provides a reaction medium for digestion-neutralization, and part is used for alkaline solution and organic coagulation aid Agent configuration; the concentrated slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com