Real-time welding seam tracking method of intelligent welding robot based on rotating arc sensing

A welding robot and rotating arc technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., to achieve the effect of strong flexibility, high stability, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

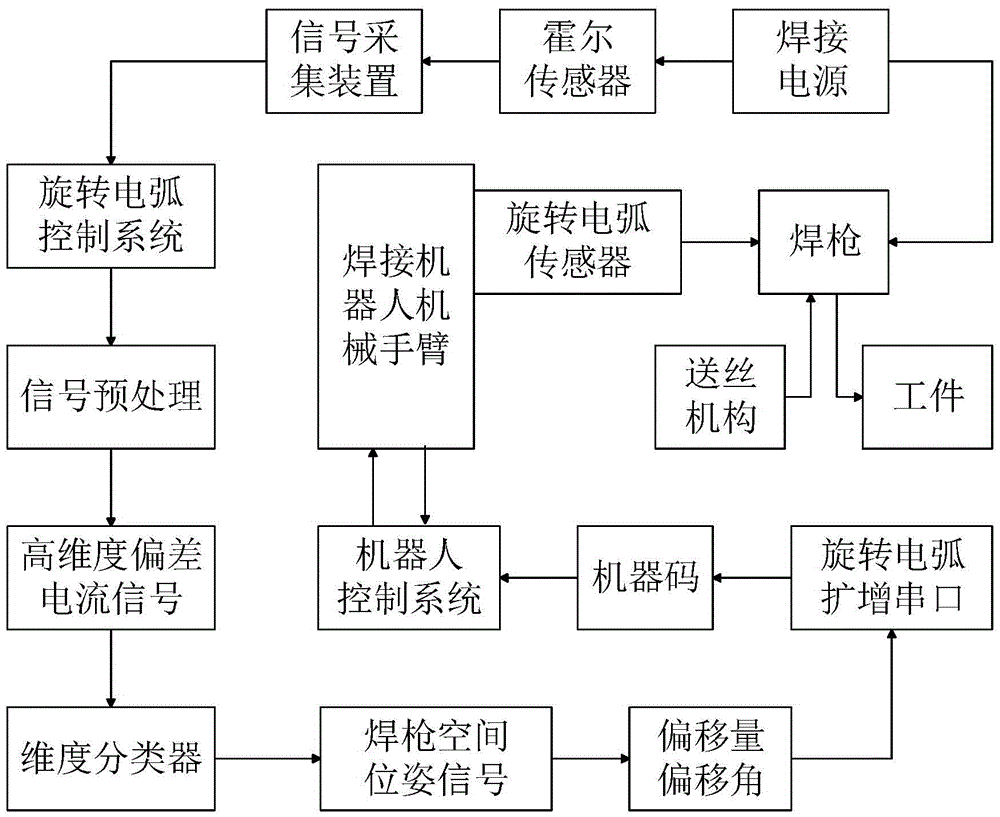

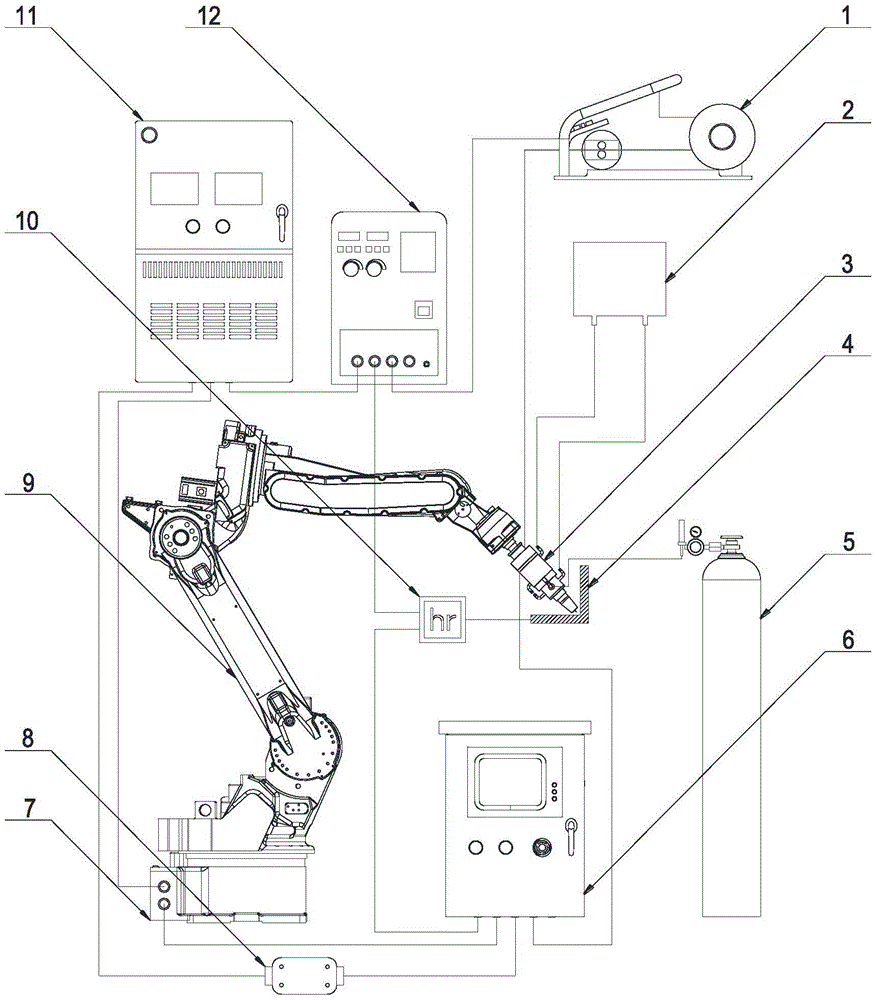

[0018] Embodiment 1, the robot real-time seam tracking system based on rotating arc sensing includes rotating arc sensor 3, rotating arc tracking system control box 6, water cooling system 2, Hall sensor 10; robot system (rotating arc real-time tracking extended serial port ) 11, mechanical arm 9, dimension classifier 7, signal preprocessing device 8; welding machine 12, workpiece and clamping device 4, wire feeder 1, protective gas cylinder 5. The two poles of the welding power supply in the welding machine 12 are respectively connected to the wire feeder 1, the Hall sensor 10 and the robot system (rotating arc real-time tracking extended serial port) 11; the Hall sensor 10 is connected to the rotating arc tracking system control box 6; the signal preprocessing device 8 are respectively connected with the rotary arc tracking system control box 6 and the robot system (rotary arc real-time tracking extended serial port) 11; the wire feeder 1 is connected with the rotary arc sens...

Embodiment 2

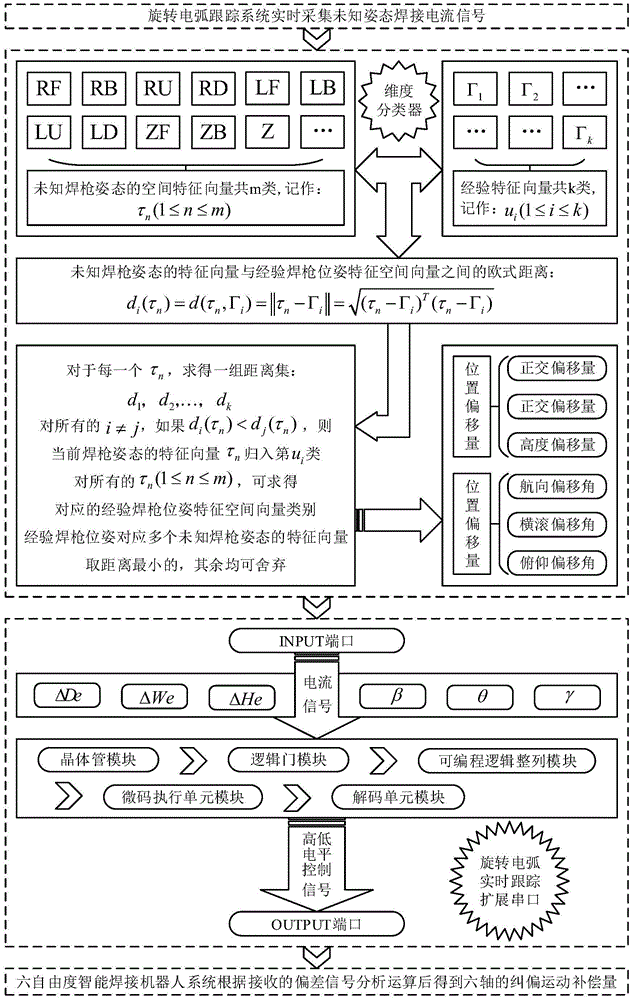

[0019] Embodiment 2, the dimension classifier is based on the Euclidean distance principle, and calculates the Euclidean distance between the feature space of the welding current data of unknown posture collected by the rotating arc tracking system and the feature vector corresponding to the empirical data sample, corresponding to the nearest fall into this category. Assume that the welding torch postures of the empirical data samples are divided into k categories, respectively u 1 , u 2 ,...,u k , each class has a corresponding feature space vector, then there are k feature space vectors, denoted as Γ 1 , Γ 2 ,…,Γ k . And assuming that there are m types of spatial feature vectors for the unknown welding torch attitude, denoted as τ m , then τ n (1≤n≤m) and u i The Euclidean distance between the eigenvectors of the empirical welding torch attitude of the class is:

[0020] d i ( τ ...

Embodiment 3

[0027] Embodiment 3, the specific flow of the real-time seam tracking method for an intelligent welding robot based on rotating arc sensing. Before welding starts, the welding robot performs initialization settings, analyzes the weld trajectory according to the welding task and welding environment settings, and analyzes the spatial motion range of the welding robot for complex space weld trajectory, and selects the appropriate weldment assembly method. The rotating arc sensor is coaxially assembled with the wrist axis of the mechanical arm 9. In order to ensure the accuracy of welding arc ignition, a suitable movement path 13 must be set. The path setting from the initial position to the starting welding point 14. The rotary arc sensor weld seam tracking system 6 is initialized and set, through its control box panel LCD screen to set the parameters related to weld seam tracking, including the arc rotation frequency and scanning radius setting of the rotary arc sensor 3, Hall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com