Automatic multi-layer shaft repair welding device

A repair welding and automatic technology, applied in the characteristics of electrodes, welding accessories, electrode support devices, etc., can solve the problem of temperature difference, and achieve the effect of reducing internal stress, improving efficiency and reducing energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but they are not used to limit the scope of the present invention.

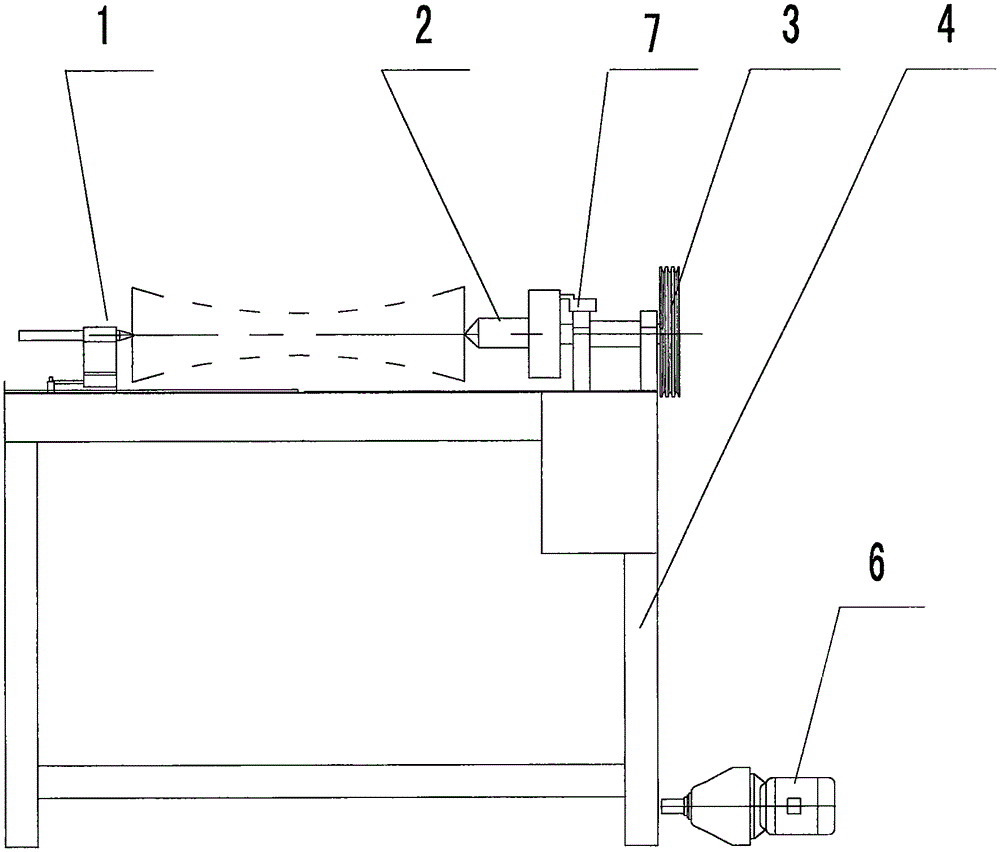

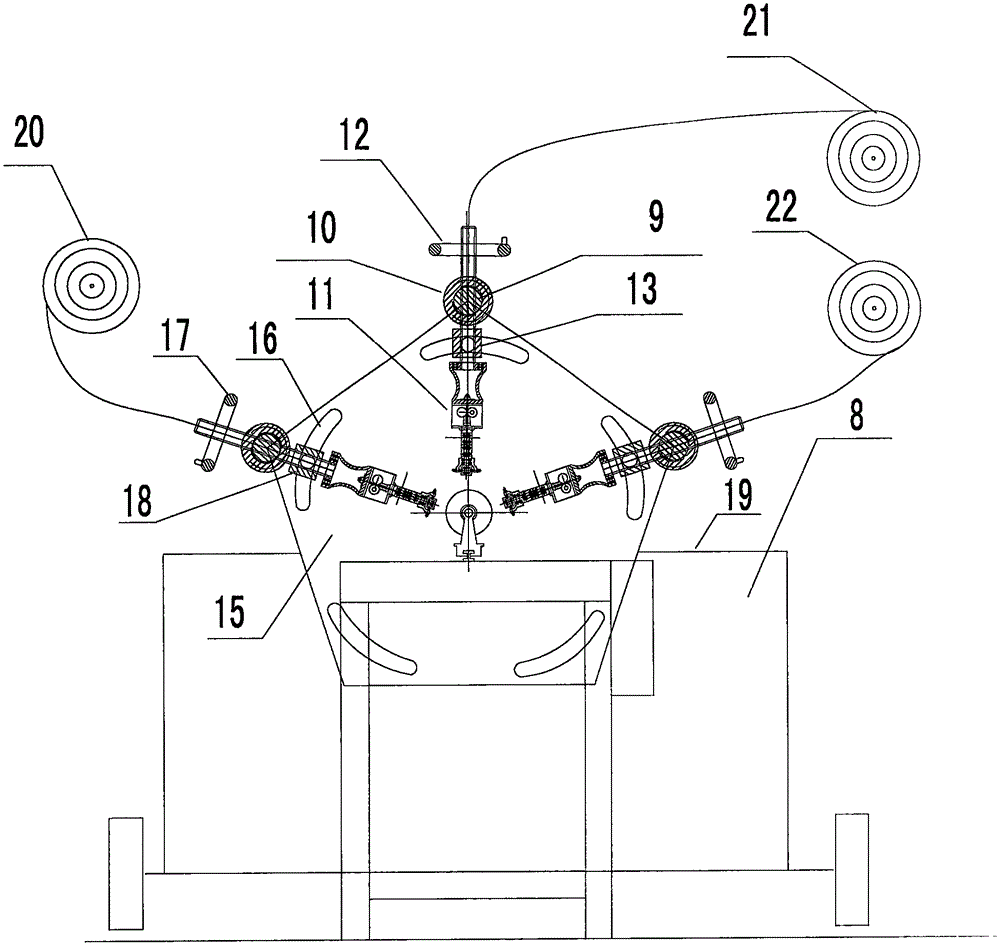

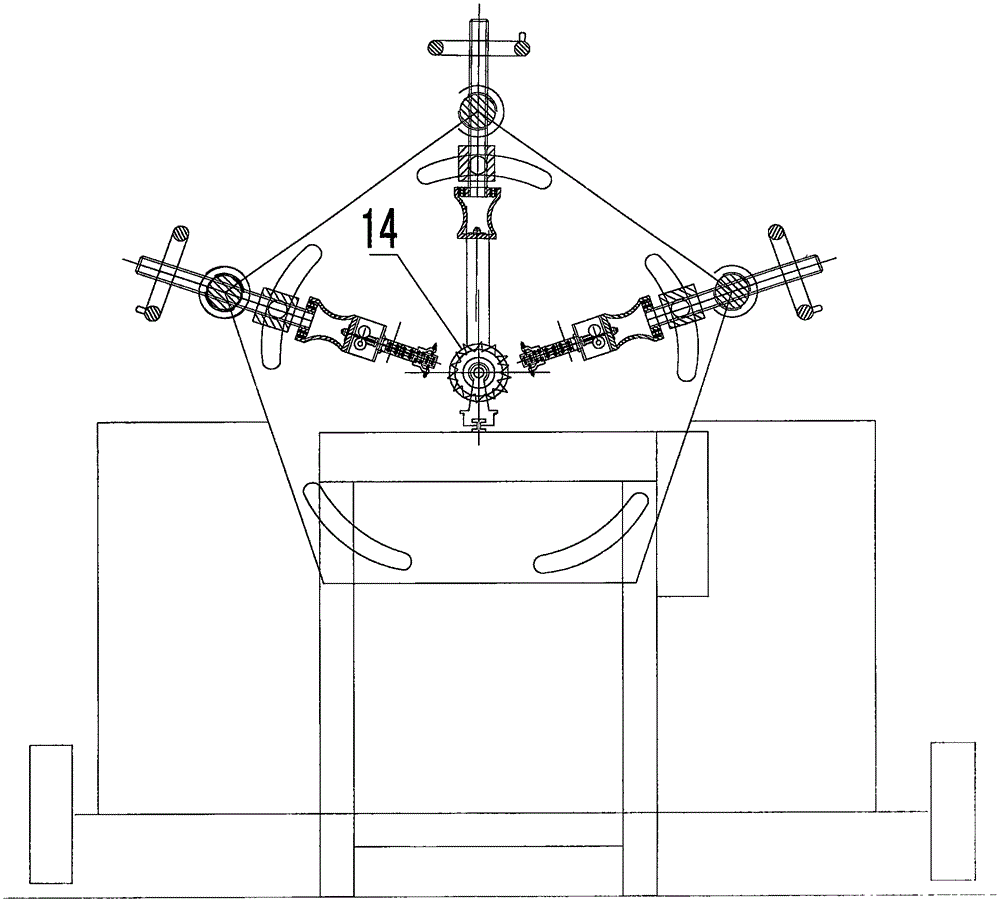

[0040] As shown in the figure, a shaft automatic repair welding equipment includes a platform 4, and the shaft rotation fixing device is arranged on the platform 4. The shaft rotation fixing device includes a clamping device 1 and a clamping rotation device 2. The top The tightening device 1 comprises a slide rail and a bracket slidably arranged on the slide rail, and the top is fixed on the bracket. The clamping and rotating device includes a fixed frame, and the fixed frame is provided with a rotating shaft. One end of the rotating shaft is connected to the rotating clamping claw, and the other end is connected to a pulley, and the pulley is connected to the driving device. The axis of the tip is aligned with the axis of the rotating shaft. The counting sensor 7 is fixed on the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com