Automatic processing production line for metal sheets

A metal sheet and production line technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of increased working time, low degree of automation, large noise and vibration, etc., to improve work efficiency, small material transmission distance, and land occupation. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

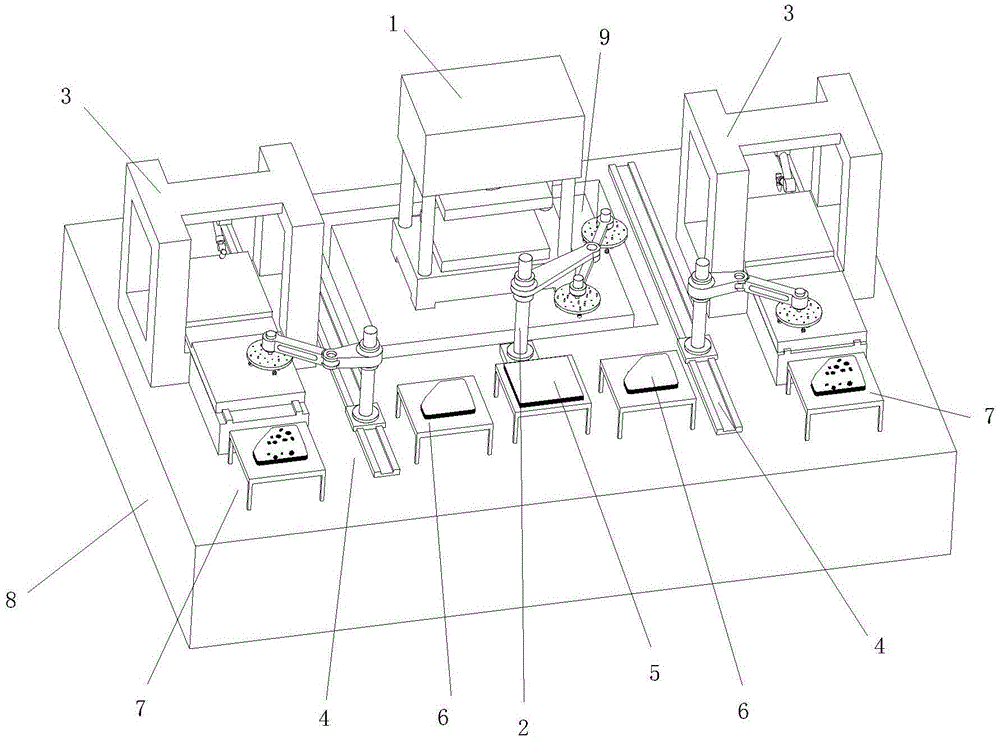

[0041] The present invention as Figure 1-8 As shown, it includes a stamping processing unit 1 (that is, a press machine) set on the foundation 8, a stamping loading and unloading manipulator 2, n sets of laser cutting processing units 3 and k sets of laser cutting loading and unloading mechanisms 4, wherein, n≥1, n Take an integer, k≥1, k takes an integer;

[0042] During work, the number of laser cutting processing units and laser cutting loading and unloading mechanisms can be different. For example, four sets of laser cutting processing units can be used, while only two sets of laser cutting loading and unloading mechanisms can be used. Each set of laser cutting loading and unloading mechanisms is two groups ( or more) laser cutting processing unit service, preferred in this case, n=k=2.

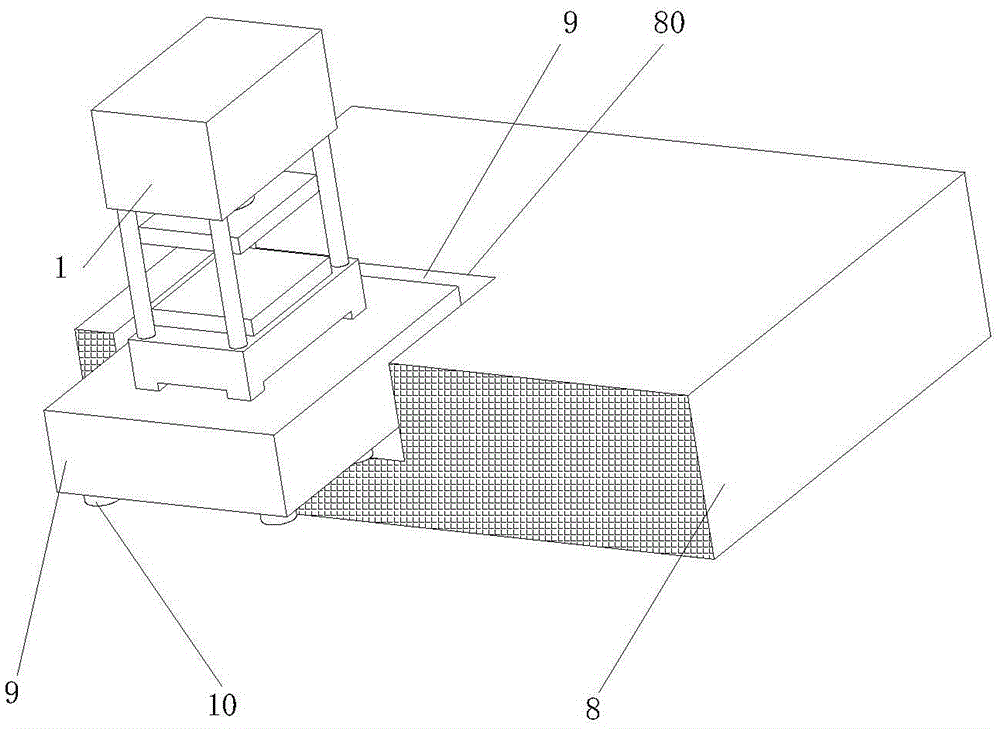

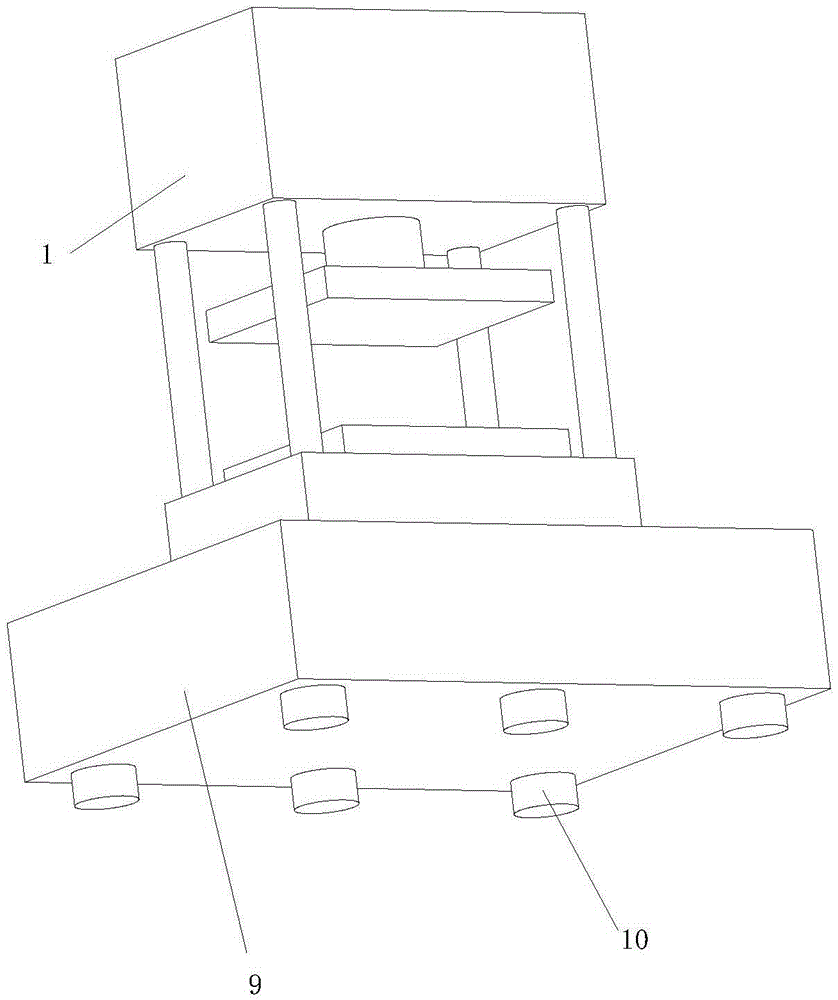

[0043] The stamping processing unit 1 is arranged on the foundation through a damping mechanism, and the stamping processing unit is used to process the blank plate into a semi-finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com