Aluminum foil of easily torn cover

A technology of easy-tear cover and aluminum foil, which can be used in flexible coverings, packaged foods, packaged items, etc., and can solve the problems of poor barrier protection effect and easy residual adhesive layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

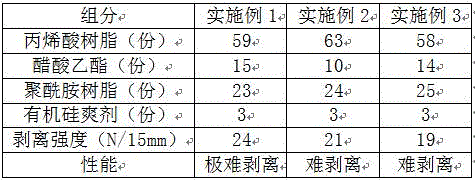

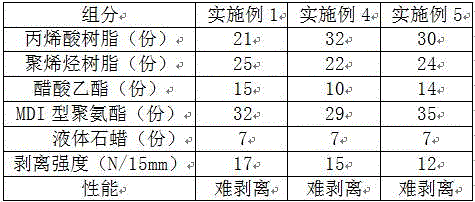

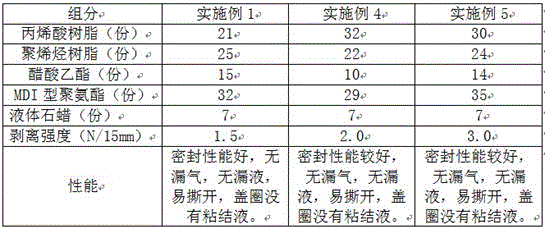

Embodiment 1

[0038] Embodiment 1: An aluminum foil with an easy-to-tear cover includes a barrier layer, a protective layer arranged on the barrier layer and a heat-sealing layer arranged below the barrier layer, and the protective layer is made of acrylic resin, ethyl acetate ester, polyamide resin and silicone slip agent, and the barrier layer is made of acrylic resin, polyolefin resin, ethyl acetate, MDI polyurethane and liquid paraffin. The protective layer is a mixture of the following ingredients:

[0039] Acrylic: 59 parts,

[0040] Ethyl acetate: 15 parts,

[0041] Polyamide resin: 23 parts,

[0042] Silicone slip agent: 3 parts.

[0043] The heat-sealing layer is formed by mixing the following components:

[0044] Acrylic: 21 parts,

[0045] Polyolefin resin: 25 parts,

[0046] Ethyl acetate: 15 parts,

[0047] MDI type polyurethane: 32 parts,

[0048] Liquid paraffin: 7 parts.

[0049] Wherein said polyolefin resin comprises:

[0050] Low-density polyethylene: 80 parts, ...

Embodiment 2

[0054] Embodiment 2: an aluminum foil with an easy-to-tear cover, including a barrier layer, also includes a protective layer arranged on the barrier layer and a heat-sealing layer arranged below the barrier layer, and the protective layer is made of acrylic resin, ethyl acetate ester, polyamide resin and silicone slip agent, and the barrier layer is made of acrylic resin, polyolefin resin, ethyl acetate, MDI polyurethane and liquid paraffin. The protective layer is a mixture of the following ingredients:

[0055] Acrylic: 58 parts,

[0056] Ethyl acetate: 14 parts,

[0057] Polyamide resin: 25 parts,

[0058] Silicone slip agent: 3 parts.

[0059] The easy-tear aluminum foil of this embodiment is made into a sample, and the conditions of other components in the sample are equal to those of Example 1, and the peel strength and performance of the protective layer and the barrier layer are tested, and the test results are recorded .

Embodiment 3

[0060] Embodiment 3: an aluminum foil with an easy-to-tear cover, including a barrier layer, also includes a protective layer arranged on the barrier layer and a heat-sealing layer arranged below the barrier layer, and the protective layer is made of acrylic resin, ethyl acetate ester, polyamide resin and silicone slip agent, and the barrier layer is made of acrylic resin, polyolefin resin, ethyl acetate, MDI polyurethane and liquid paraffin. The protective layer is a mixture of the following ingredients:

[0061] Acrylic: 63 parts,

[0062] Ethyl acetate: 10 parts,

[0063] Polyamide resin: 24 parts,

[0064] Silicone slip agent: 3 parts.

[0065] The easy-tear aluminum foil of this embodiment is made into a sample, and the conditions of other components in the sample are equal to those of Example 1, and the peel strength and performance of the protective layer and the barrier layer are tested, and the test results are recorded .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com