Biological denitrification device

A technology for biological denitrification and purification pool, applied in the field of biological denitrification, can solve the problems of limited application scope, low process flexibility, large space occupation, etc., and achieve the effect of reducing production cost, high process flexibility, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

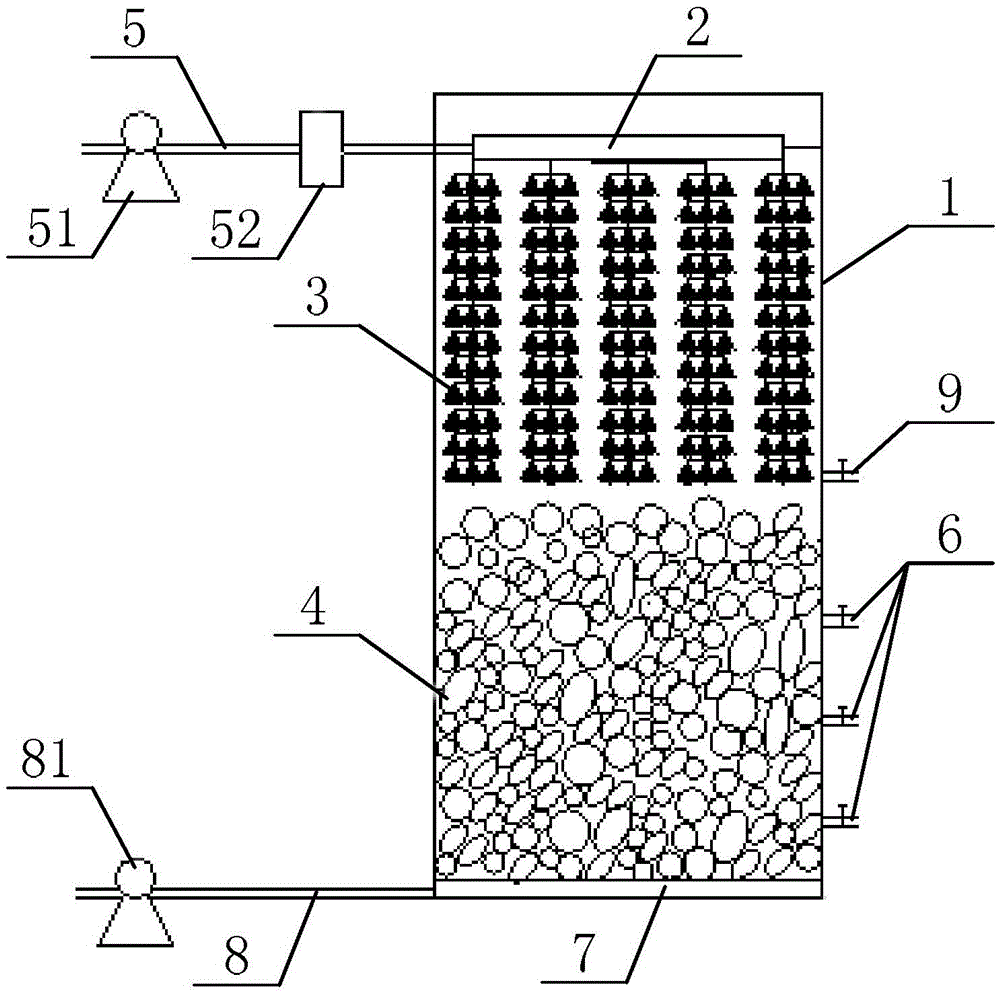

[0021] Such as figure 1 As shown, a biological denitrification device, its specific structure may include: a purification pool 1, a water distributor 2, a fiber packing 3 with aerobic nitrifying microorganisms attached, a solid packing 4 with anaerobic denitrifying microorganisms attached, a purification pool Water inlet pipe 5, purification tank water outlet 6, backwash air pan 7, backwash water inlet pipe 8 and backwash water outlet 9; water distributor 2 is located on the upper part of purification tank 1, and the water inlet of water distributor 2 is connected The pool inlet pipe 5 is connected; the fiber filler 3 is set in the purification tank 1 and is located below the water distributor 2; the solid filler 4 is set in the purification tank 1 and is located below the fiber filler 3; multiple purification tank outlets 6 It is located at different heights on the side wall of the purification tank 1, and the height of the water outlet 6 of each purification tank is lower th...

Embodiment approach

[0023] (1) The water distribution pipe of the water distributor 2 mainly has two functions: one is that when the sewage to be treated enters the water distributor 2 from the water inlet pipe 5 of the purification tank, the water distribution pipe of the water distributor 2 can discharge the sewage to be treated in the purification tank 1 distributes water evenly, and the other provides support for the fiber filler 3.

[0024] (2) Aerobic nitrifying microorganisms (the aerobic nitrifying microorganisms can be nitrosifying bacteria and nitrifying bacteria) are attached to the fibrous packing 3, and when the sewage to be treated flows out from the water distribution pipe of the water distributor 2, it contacts the fibrous packing 3, and The nitrification reaction occurs under the action of aerobic nitrifying microorganisms, thereby realizing the nitrification treatment of the sewage to be treated.

[0025] In practical application, the fiber filler 3 can be a plurality of tubular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com