Functional polymer with surface activity, preparation method therefor and application of functional polymer with surface activity

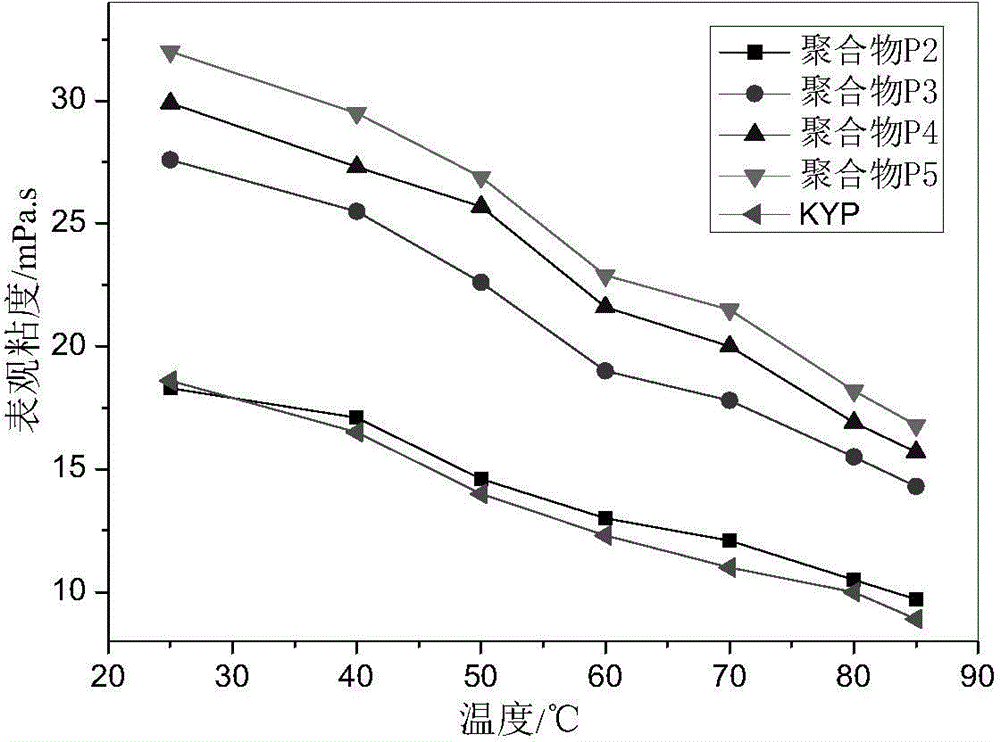

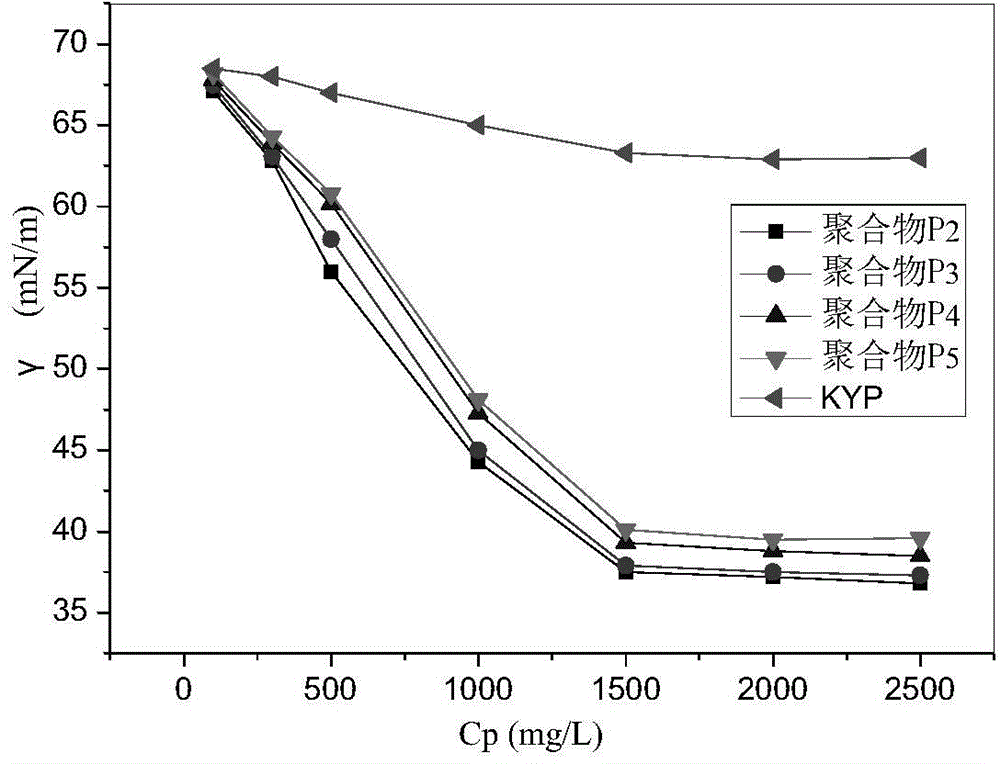

A functional polymer and surface active technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve enhanced oil recovery, good cationic precipitation resistance and temperature resistance, and solve the problem of temperature resistance and resistance to high inorganic prices The effect of poor cationic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

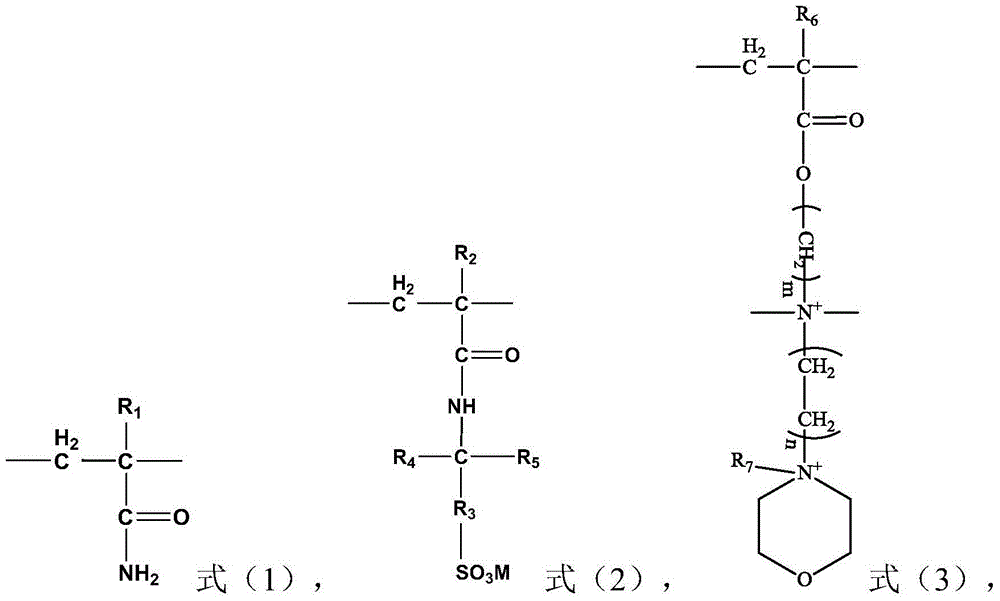

Method used

Image

Examples

Embodiment 1

[0067] Adopt aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 0.25g structure monomer YD-1 (Shanghai Boyihe chemical industry) as water-soluble surface active monomer, 19.75g propylene as shown in formula (13) Amide, 5.0g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomer and distilled water, the total content of monomer is 10% by weight, fully stirred to the The solution turned into a clear solution. Then add 25 mg of auxiliary agent urea, 75 mg of disodium edetate, 1 mL of ammonia water and 10 mg of isopropanol, and at the same time adjust the pH value of the system to 6 with sodium hydroxide, and feed high-purity nitrogen with a volume concentration of 99.99% for 30 minutes. Oxygen was removed from the polymerization flask. Then add 20 mg of ammonium persulfate and 10 mg of sodium bisulfite in sequence, continue to pass high-purity nitrogen gas for 10 minu...

Embodiment 2

[0071] Adopt aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 0.1875g structure monomer YD-1 (Shanghai Boyihe chemical industry) as the water-soluble surface active monomer, 24.1875g propylene shown in formula (13) Amide, 13.125g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomer and distilled water, the total content of monomer is 15% by weight, fully stirred to the The solution turned into a clear solution. Then add 25 mg of auxiliary agent urea, 75 mg of disodium edetate, 1 mL of ammonia water and 10 mg of isopropanol, and at the same time adjust the pH value of the system to 7 with sodium hydroxide, and feed high-purity nitrogen with a volume concentration of 99.99% for 30 minutes. Oxygen was removed from the polymerization flask. Then add 20mg of ammonium persulfate and 10mg of sodium bisulfite successively, and continue to pass high-purity nitrogen gas ...

Embodiment 3

[0075] Adopt aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 0.25g structure monomer YD-2 (Shanghai Boyihe chemical industry) as water-soluble surface active monomer, 34.75g propylene as shown in formula (14) Amide, 15 g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomers and distilled water, the total content of monomers is 20% by weight, fully stirred into the solution in the polymerization reaction bottle turned into a clear solution. Then add 50mg of auxiliary agent urea, 100mg of disodium ethylenediaminetetraacetic acid, 1mL of ammonia water and 5mg of N,N-methylenebisacrylamide, and at the same time adjust the pH value of the system to 8.0 with sodium hydroxide. High-purity nitrogen for 30 minutes to remove oxygen from the polymerization flask. Then add 15mg of ammonium persulfate and 10mg of sodium bisulfite successively, and continue to pass high-pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com