A kind of polymer with surface active function and its preparation method and application

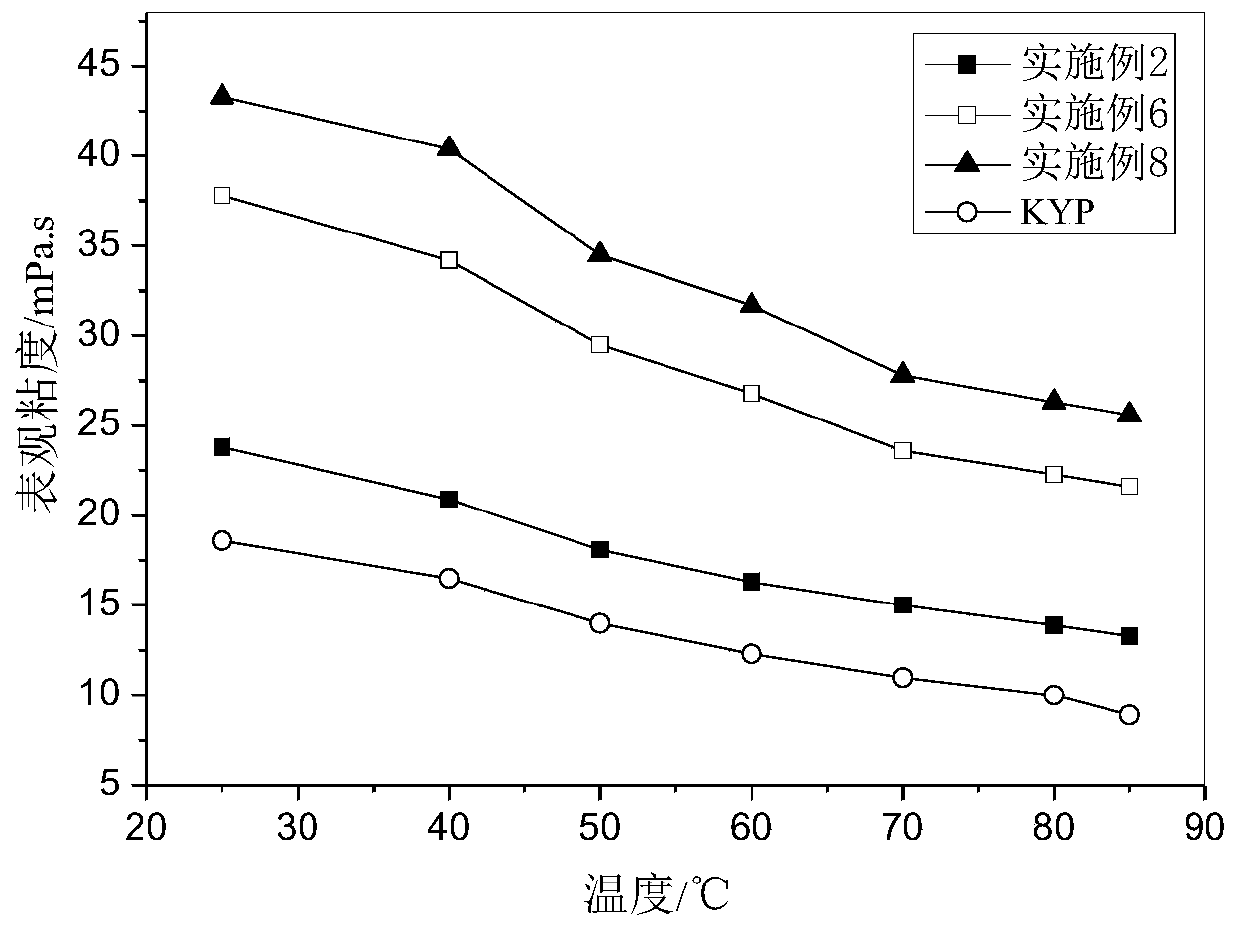

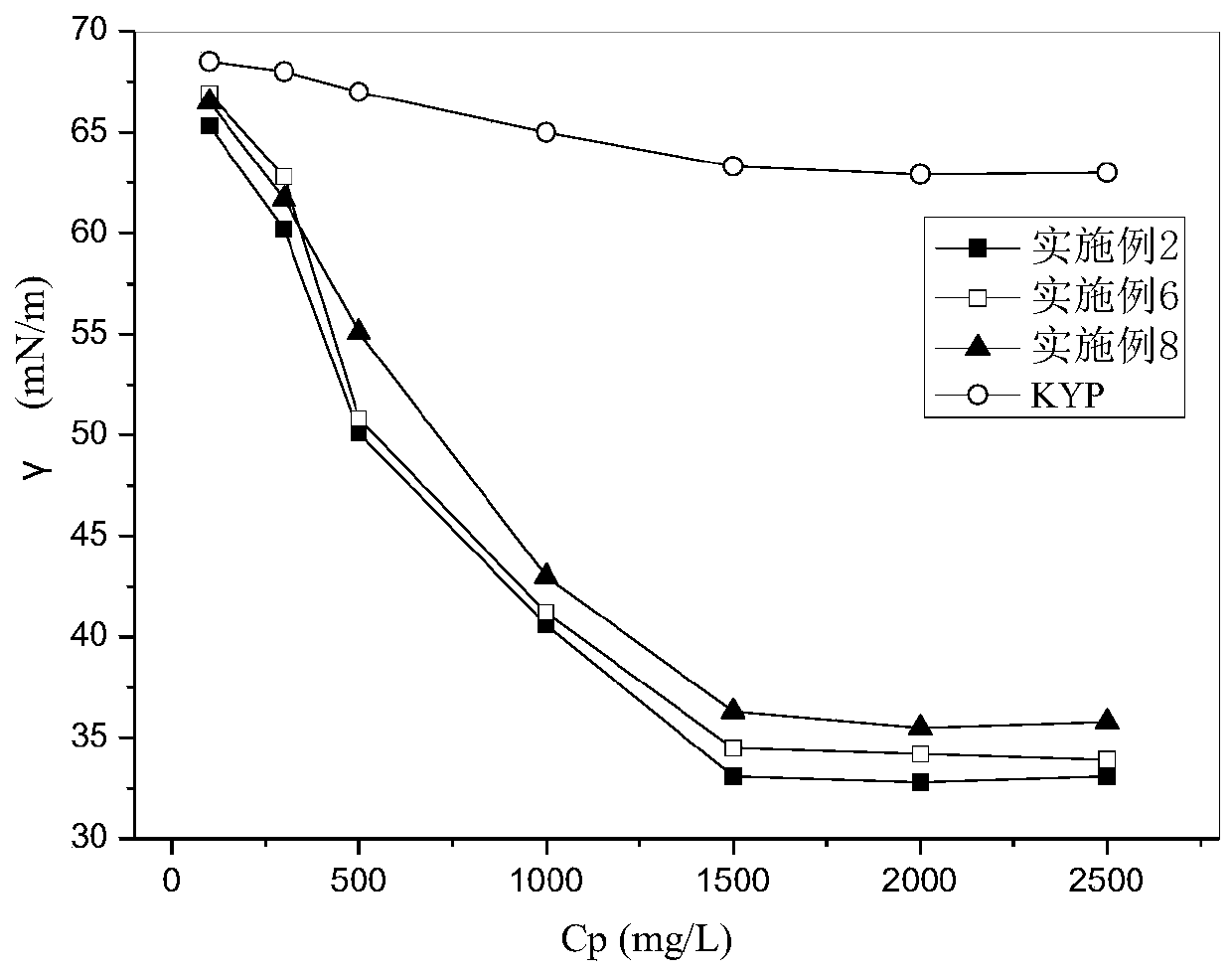

A technology of surface activity and polymer, applied in the field of polymers, can solve the problems that polymers used for oil displacement cannot have good surface activity, thickening water medium ability and temperature resistance and salt resistance ability, etc., to achieve enhanced oil recovery , solve the effect of poor temperature and salt resistance and good surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

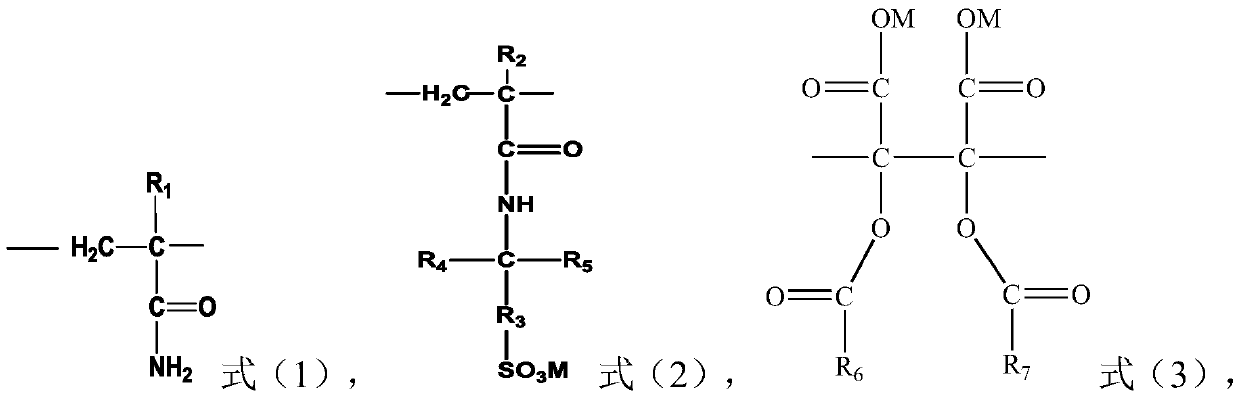

[0071] This example is used to illustrate the polymer with surface active function and its preparation method according to the present invention.

[0072] Adopt aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 6.00g as the structural monomer DTE-1 (Zhangjiagang Tianding Chemical Co., Ltd.) shown in formula (14) as water-soluble surface-active monomer, 37.5g Acrylamide, 19.0g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomers and distilled water, the total content of monomers is 25% by weight, fully stirred into the polymerization reaction bottle The solution turned into a transparent solution. Then add 25mg of auxiliary urea, 75mg of disodium edetate, 1mL of ammonia water and 10mg of isopropanol, and at the same time adjust the pH value of the system to 7.8 with sodium hydroxide. % high-purity nitrogen for 30 minutes to remove the oxygen in the polymerizatio...

Embodiment 2

[0076] This example is used to illustrate the polymer with surface active function and its preparation method according to the present invention.

[0077]Adopt aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 5.75g as the structural monomer DTE-2 (Zhangjiagang Tianding Chemical Co., Ltd.) shown in formula (15) as water-soluble surface-active monomer, 37.0g Acrylamide, 19.75g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomers and distilled water, the total content of monomers is 24% by weight, fully stirred into the polymerization reaction bottle The solution turned into a transparent solution. Then add 25 mg of auxiliary agent urea, 75 mg of disodium edetate, and 1 mL of ammonia water, and at the same time adjust the pH value of the system to 7.8 with sodium hydroxide, place the reactor in a water bath, and feed high-purity nitrogen with a volume concentratio...

Embodiment 3

[0081] This example is used to illustrate the polymer with surface active function and its preparation method according to the present invention.

[0082] Adopt aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 4.25g as the structural monomer DTE-3 shown in formula (16) (Zhangjiagang Tianding Chemical Co., Ltd.) as water-soluble surface-active monomer, 40.0g Acrylamide, 18.25g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomers and distilled water, the total content of monomers is 26% by weight, fully stirred into the polymerization reaction bottle The solution turned into a transparent solution. Then add 50 mg of auxiliary agent urea, 100 mg of disodium edetate, 1 mL of ammonia water and 5 mg of N,N-methylenebisacrylamide, and at the same time adjust the pH value of the system to 8.0 with sodium hydroxide, place the reactor in a water bath, Introduce high-pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com