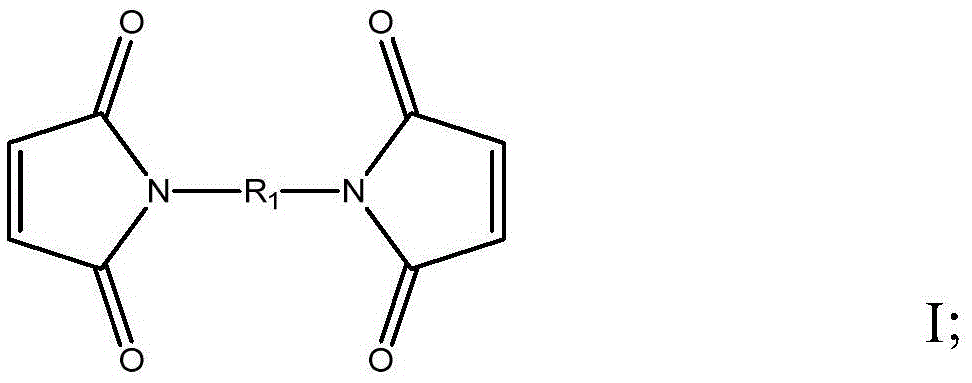

Bismaleimide polymer allowing long-term storage and preparation method thereof

A bismaleimide, maleimide phenoxy technology, applied in the field of bismaleamide polymer and its preparation, can solve the change of product chemical structure, limit storage time and application field, polymerization reaction or Curing reaction and other problems, to achieve the effect of expanding application methods and application fields, prolonging storage period, and improving chemical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

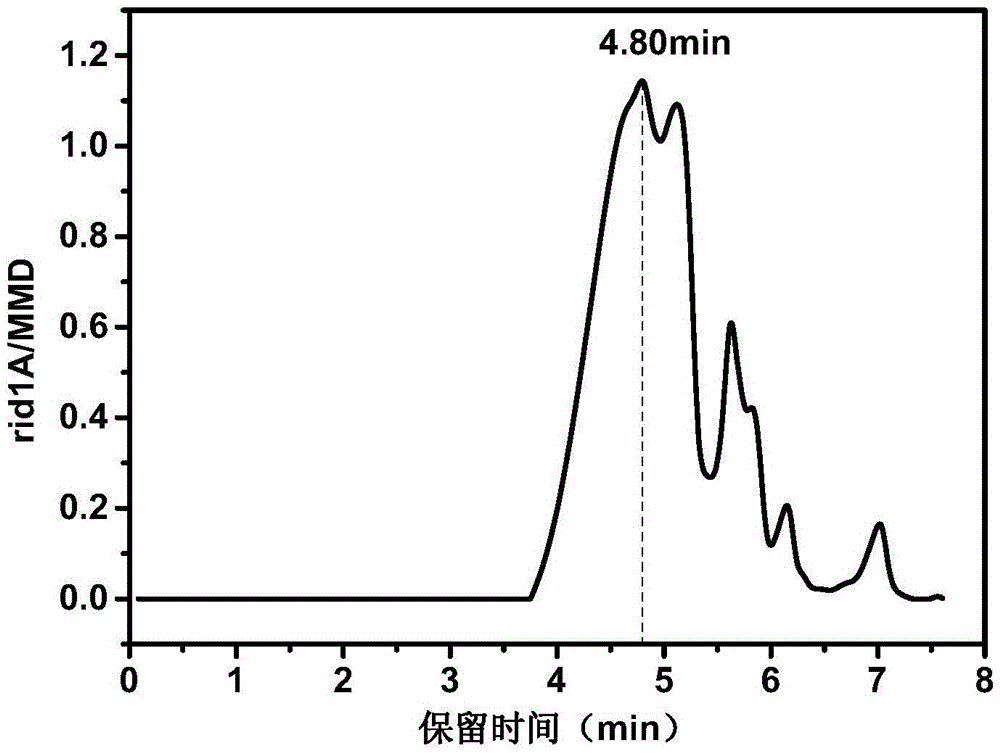

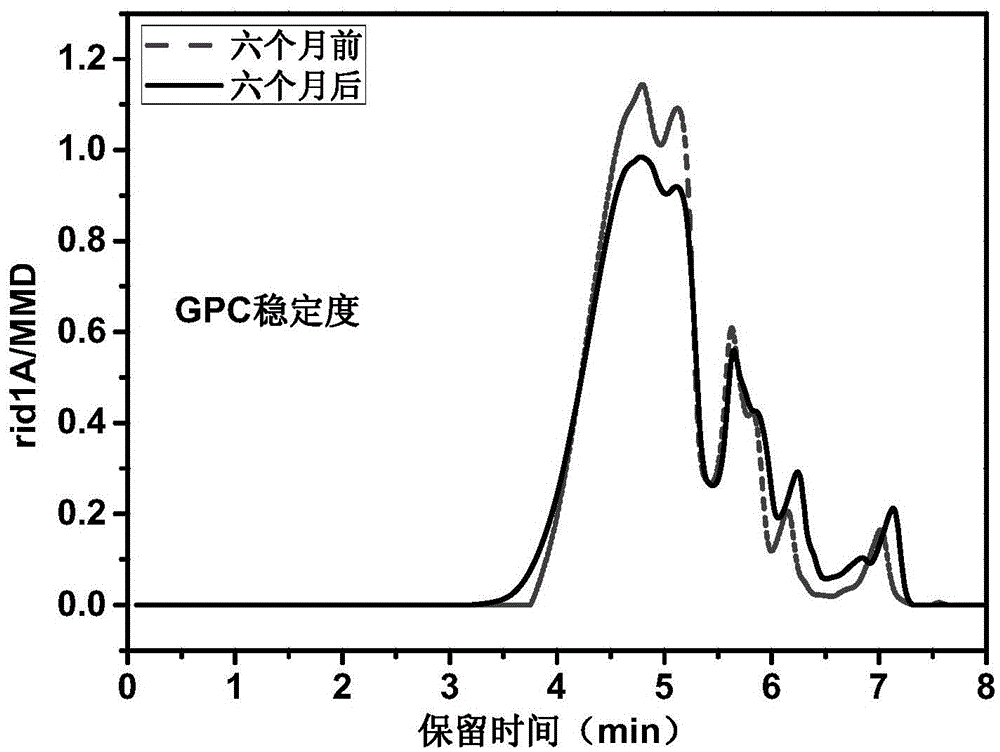

[0040] Bismaleimide polymers were prepared as follows:

[0041] (1) Put 20g of N,N'-(methylenediphenyl)bismaleimide into a 250mL three-necked flask, add 80g of γ-butyrolactone solvent, heat to 120°C, and stir until completely dissolved to obtain Solution A, standby;

[0042] (2) Put 3.572g of barbituric acid and 0.011g of azobisisobutyronitrile into another 250mL three-necked flask, add 14.29g of γ-butyrolactone solvent, and stir at room temperature for 30 minutes to obtain solution B for later use;

[0043] (3) adding the solution B to the solution A at one time, incubating and stirring at 120°C for 6 hours, and cooling to room temperature to obtain a wine red reaction solution;

[0044] (4) Add the reaction solution to 1300 g of ethanol, stir well until the product is completely precipitated, and obtain a light yellow suspension. After the solid is separated by centrifugation, the solid product is washed with ethanol, and then baked and dried at 80° C. for 24 hours , 19.34...

Embodiment 2

[0048] Bismaleimide polymers were prepared as follows:

[0049] (1) Put 20g of N,N'-(methylenediphenyl)bismaleimide into a 250mL three-necked flask, add 80g of γ-butyrolactone solvent, heat to 120°C, and stir until completely dissolved to obtain Solution A, standby;

[0050] (2) Put 3.572g of barbituric acid and 0.011g of benzoyl peroxide into another 250mL three-necked flask, add 14.29g of gamma-butyrolactone solvent, and stir at room temperature for 30 minutes to obtain solution B for later use;

[0051] (3) adding the solution B to the solution A at one time, incubating and stirring at 120°C for 6 hours, and cooling to room temperature to obtain a wine red reaction solution;

[0052] (4) Add the reaction solution to 1300 g of methanol, stir well until the product is completely precipitated, and obtain a light yellow suspension. After the solid is separated by centrifugation, the solid product is washed with methanol, and then baked and dried at 80° C. for 24 hours , 19.58...

Embodiment 3

[0054] Bismaleimide polymers were prepared as follows:

[0055] (1) Put 20g of N,N'-(1,3-phenylene)bismaleimide into a 250mL three-necked flask, add 80g of N-methylpyrrolidone, heat to 110°C, stir well until it dissolves completely, and get Solution A, standby;

[0056] (2) Put 3.572g of barbituric acid and 0.011g of benzoyl peroxide into another 250mL three-necked flask, add 14.29g of N-methylpyrrolidone, and stir at room temperature for 30 minutes to obtain solution B for later use;

[0057] (3) adding the solution B to the solution A at one time, incubating and stirring at 110°C for 6 hours, and cooling to room temperature to obtain a wine red reaction solution;

[0058] (4) The reaction solution is added to 1300g of ethanol, fully stirred until the product is completely precipitated to obtain a light yellow suspension, after the solid is separated by suction filtration, the solid product is washed with ethanol, and then baked and dried at 80°C for 24 After 1 hour, 18.87 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com