Method for improving wear resistance and high-temperature resistance of stirring head for stirring and friction welding

A technology of friction stir welding and stirring head, which is applied in the direction of coating, metal material coating process, etc., can solve the problem of limited wear resistance of metal materials, difficult wear resistance of stirring head and high temperature thermal stability, which affect the reliability of welded joints and stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

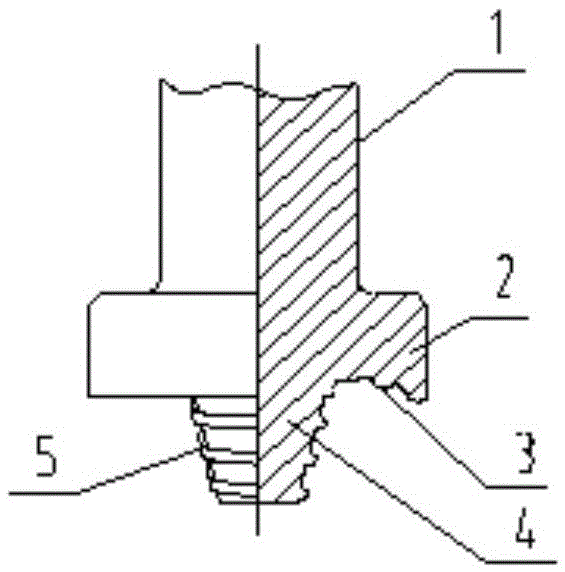

Embodiment 1

[0061] According to the method of the present invention, the wear-resistant and high-temperature-resistant coating is prepared on the processed and manufactured stirring head concave shoulder and the tapered stirring needle substrate, and the weight percentage of the wear-resistant and high-temperature resistant coating raw material powder is 25% WC+1% La 2 o 3 +3.0%Al+3.5%Ti+0.8%Nb, the balance is Ni60, and its powder particle size is: -100~+200 mesh; La 2 o 3 The purity of rare earth oxides is 99.99%; nickel-based self-fluxing alloy Ni60, the mass percentage of its components is carbon 1.7%, silicon 4.5%, boron 3%, iron 3.5%, chromium 15%, and the balance is Ni; The filling method adopts the preset powder method to preset uniform nickel-based ceramic composite alloy powder with a thickness of 1mm on the surface of the concave shoulder of the stirring head; preset uniform nickel-based ceramic composite alloy powder with a thickness of 0.8mm on the surface of the conical stirri...

Embodiment 2

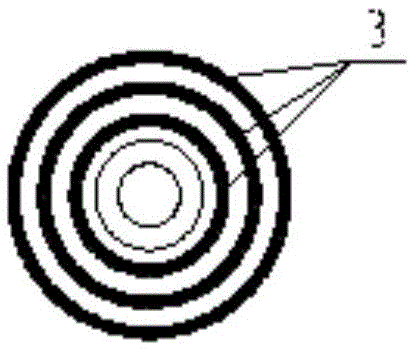

[0066] According to the method of the present invention, ring-shaped and spiral wear-resistant and high-temperature resistant coatings are prepared on the processed and manufactured stirring head concave shaft shoulder and the tapered stirring needle substrate, and the raw material powder formula and laser cladding process parameters of the wear-resistant and high-temperature resistant coating are the same as Embodiment 1 is the same. The difference from Example 1 is that the uniform nickel-based ceramic composite alloy powder with a thickness of 0.8-1.8 mm is preset on the surface of the concave shoulder of the stirring head by the method of preset powder; ~1.0mm uniform nickel-based ceramic composite alloy powder; using the same coating raw material formula and deposition process parameters as in Example 1 to prepare a coating different from Example 1 on the concave shoulder and conical stirring pin substrate with reasonable Annular and spiral wear-resistant and high-tempera...

Embodiment 3

[0070] According to the method of the present invention, ring-shaped and spiral wear-resistant and high-temperature resistant coatings are prepared on the processed and manufactured stirring head concave shoulder and the tapered stirring needle substrate. The raw material powder formula and preparation process of the wear-resistant and high-temperature resistant coating are all the same as those in the examples. Two same. The difference is that the rotation speed of the stirring head lower than the second embodiment is selected, and the higher welding speed is used to weld TC4 titanium alloy high-melting point materials, which are respectively 750r / min and 100mm / min, the rotation speed has decreased by 18.5%, and the welding speed has increased 30%. Compared with Example 1 and Example 2, the weld structure after welding shows that the grains of the weld structure are equiaxed, the degree of uniformity of the grains is greatly improved, and the refinement is remarkable. The sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com