Preparation method of alginate fiber

A technology of seaweed fiber and sodium alginate, which is applied in fiber processing, wet spinning, alginate artificial filament, etc., can solve the problems of restricting the development of seaweed fiber, large waste water discharge, and serious water consumption, etc. Excellent performance and reproducibility, short production process, and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

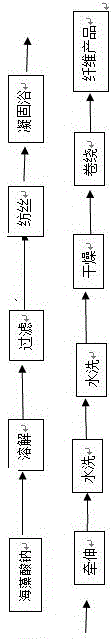

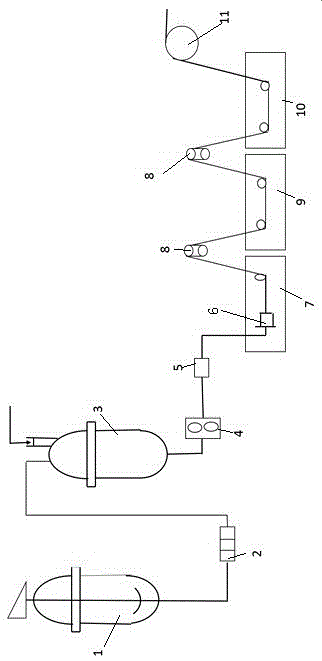

[0015] The present invention includes the extraction of sodium alginate, the preparation of sodium alginate spinning solution and wet spinning, and integrates and simplifies the process, eliminating the need for ethanol precipitation and drying in the extraction process of sodium alginate in the prior art. Dry crushing and redissolution during the preparation of sodium alginate spinning solution can not only reduce the discharge of waste liquid, but also reduce the degradation of sodium alginate. like figure 1 As shown in the schematic diagram of the process flow of the present invention, the preparation method of the seaweed fiber of the present invention specifically includes the following steps;

[0016] Step 1. Extraction of sodium alginate: Take 60g of kelp and place it in 1L of dilute hydrochloric acid (0.1mol / L), soak it at room temperature for 12h, wash off the surface extract with deionized water, add an appropriate amount of 3%Na 2 C0 3 Soak in the solution for 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com