Ultralow NOx pulverized coal burner

A pulverized coal burner, ultra-low technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems that cannot be directly used, so as to reduce the generation of NOx, realize NOx emissions, and reduce NOx The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

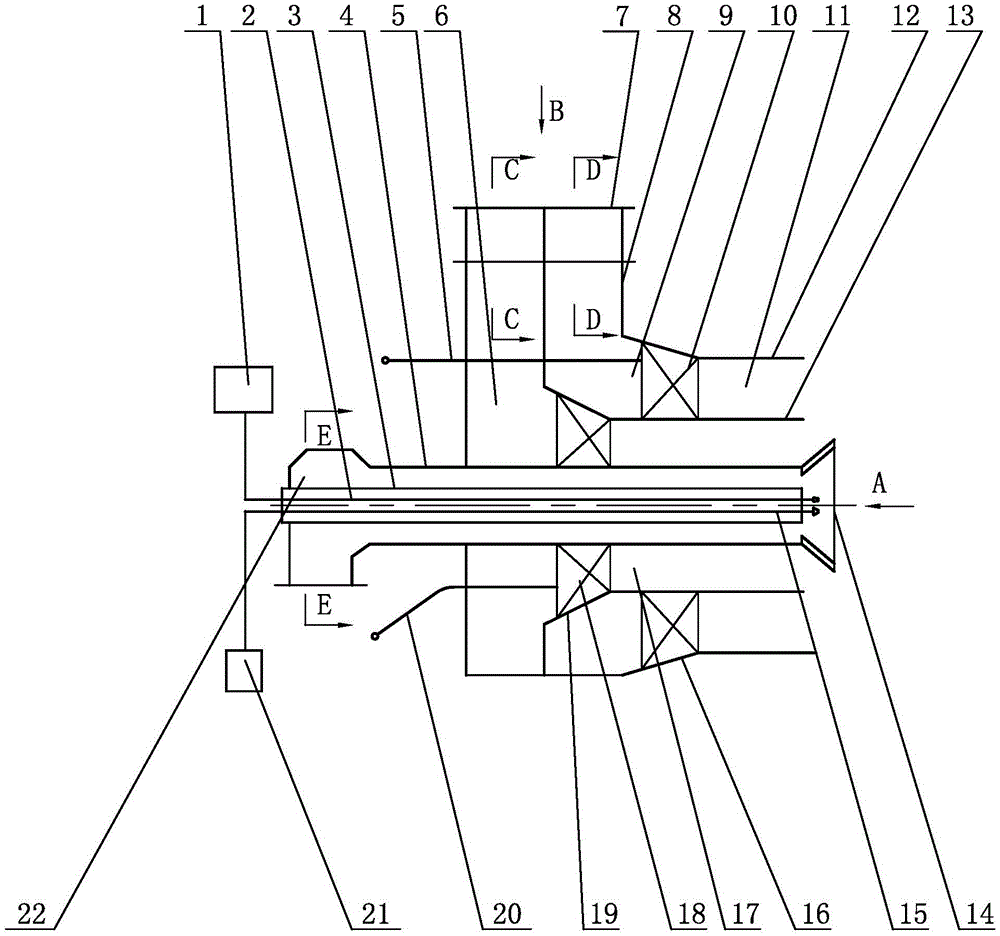

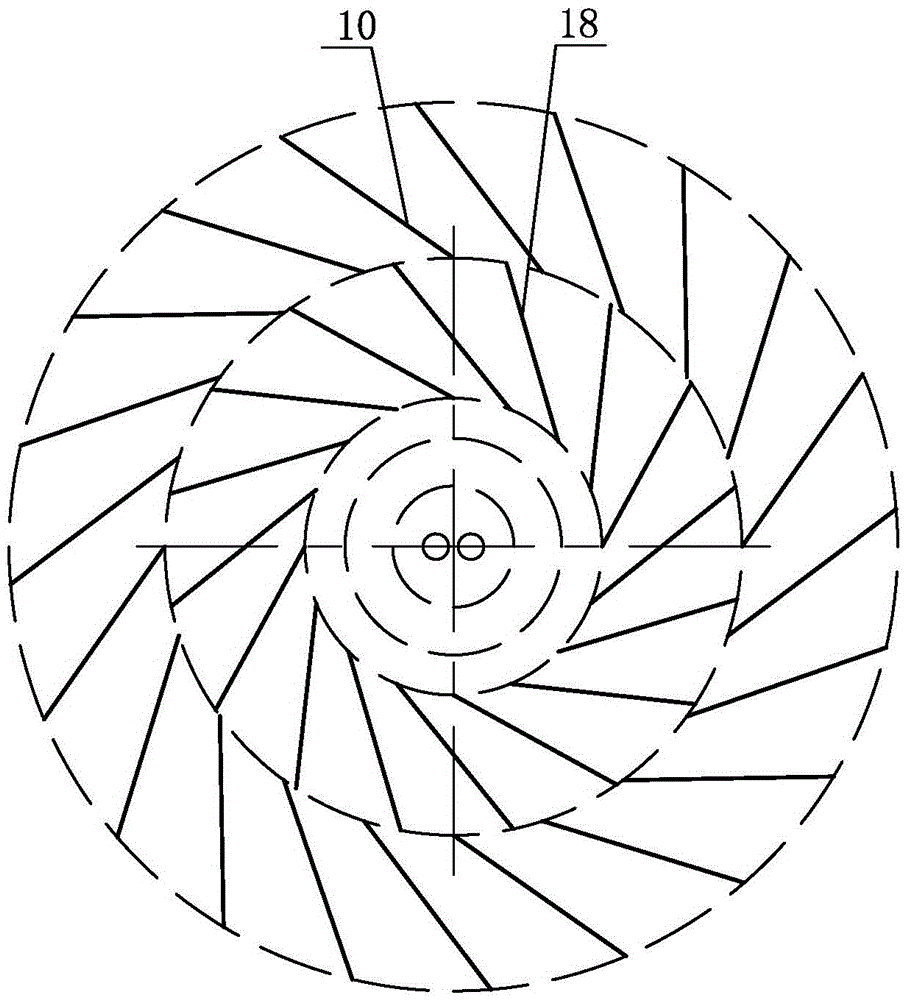

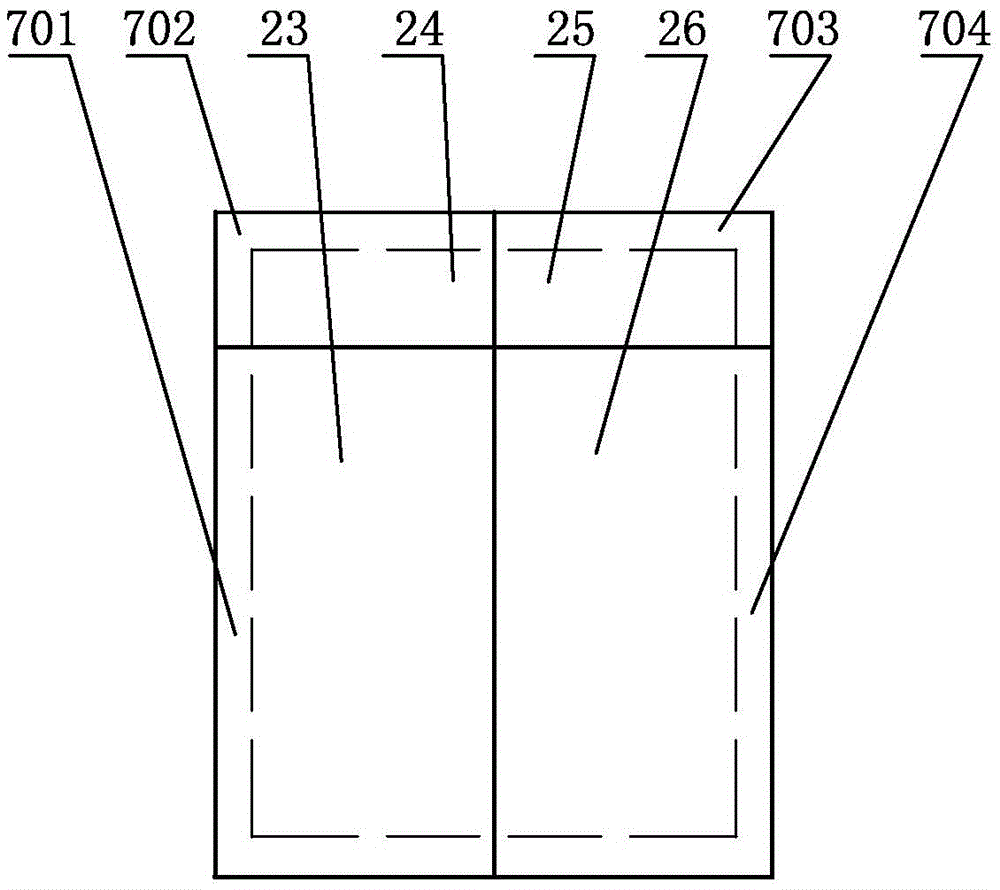

[0021] Refer to 1, figure 2 , image 3 , Figure 4 and Figure 5 , an ultra-low NO of the present invention x The pulverized coal burner includes a secondary air box 8, an electric damper 7, a coaxial primary air duct 4, a secondary internal air duct 13 and a secondary external air duct 12, and the primary air duct 4 is arranged on the axis There is a central tube 3 inside, the central tube 3 is provided with a light vehicle oil gun 15 and an ignition electrode 2, the light oil gun 15 is connected to an oil pump 21, and the ignition electrode 2 is connected to an ignition transformer 1 , which is characterized in that the secondary air box 8 is provided with an inner secondary air chamber 6 and an outer secondary air chamber 9; one end of the inner secondary air chamber 6 is connected to the primary air pipe 4 and the secondary inner air chamber The inner secondary air passage 17 between the air ducts 13 is connected, and the other end is provided with a first return air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com