Correction method for down-conversion fluorescence intensity ratio temperature measurement technology

A technology of fluorescence intensity ratio and technology, applied in thermometers, measuring devices, measuring heat and other directions, can solve the problems of inaccurate temperature measurement results of temperature measurement technology, and achieve the effect of strong anti-interference ability, improved accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

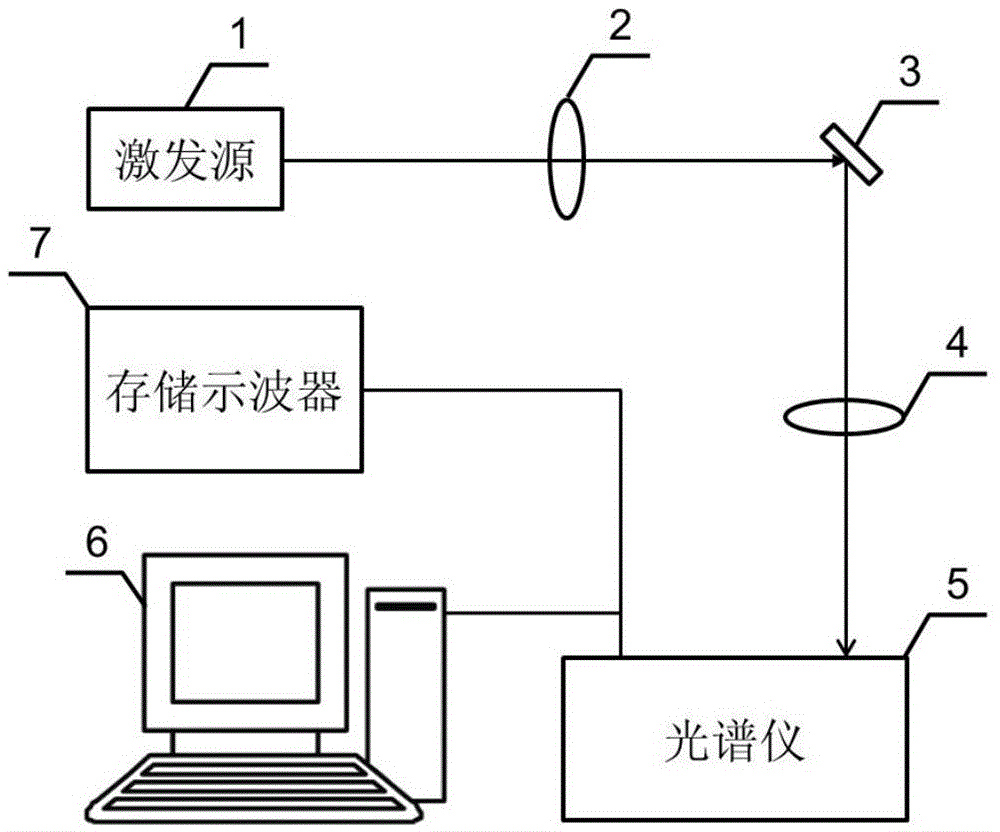

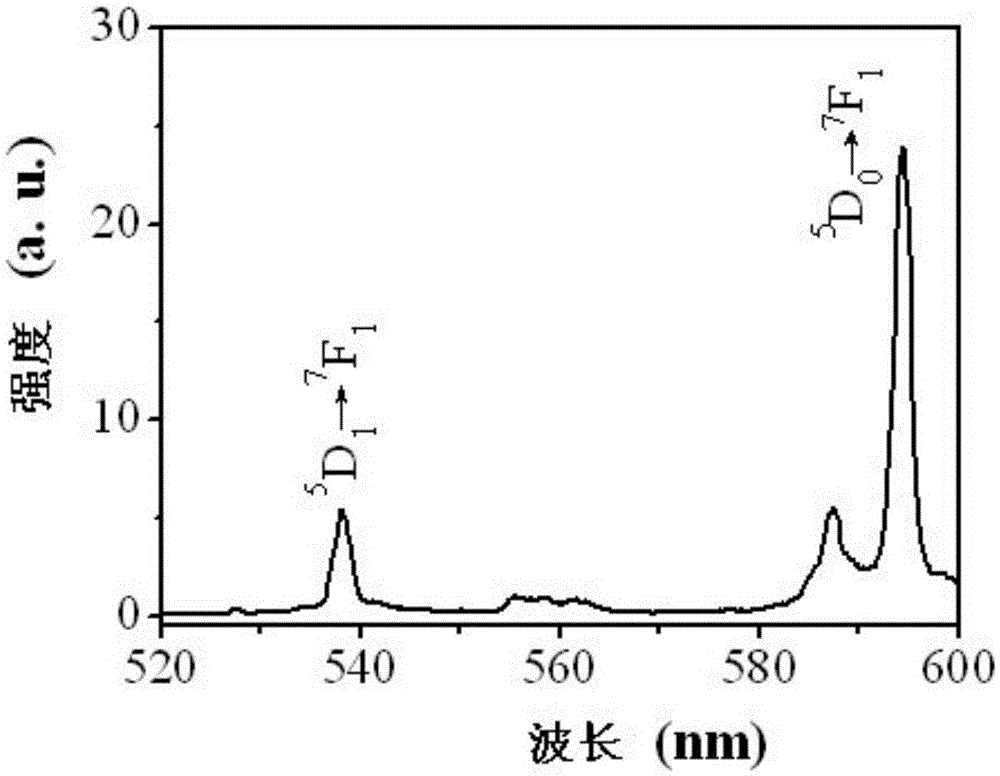

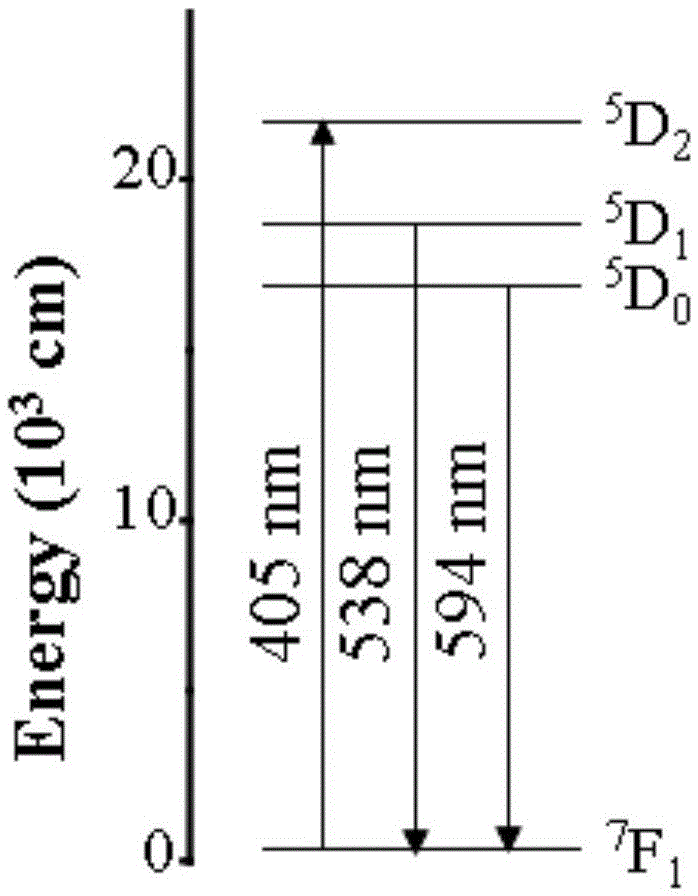

[0017] Specific Embodiment 1: In this embodiment, a correction method for down-conversion fluorescence intensity ratio temperature measurement technology is carried out according to the following steps: 1. The pulsed excitation light emitted by the excitation source is converged by a convex lens and irradiated onto the temperature-sensitive temperature sensor doped with rare earth ions. On the material, the down-converted fluorescence emitted by the temperature-sensing material doped with rare earth ions is converged into the computer-controlled grating spectrometer through another convex lens, and the fluorescence spectrum collected by the computer-controlled grating spectrometer has two fluorescence emission peaks, respectively Fluorescent emission peaks produced by the radiative transition from two adjacent and thermally coupled energy levels of rare earth ions to the lower energy level, the fluorescence wavelength emitted by the upper energy level A is shorter than the wavel...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that: the excitation source is a 405nm light-emitting diode. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the temperature-sensing material doped with rare earth ions is Eu 3+ Doped with temperature-sensitive materials. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com