Method for preparing poultry artificial bear gall powder

A technology for bear bile powder and poultry is applied in the field of preparation of artificial bear bile powder for poultry, which can solve the problems of low efficiency and complicated extraction method, and achieve the effects of high efficiency and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

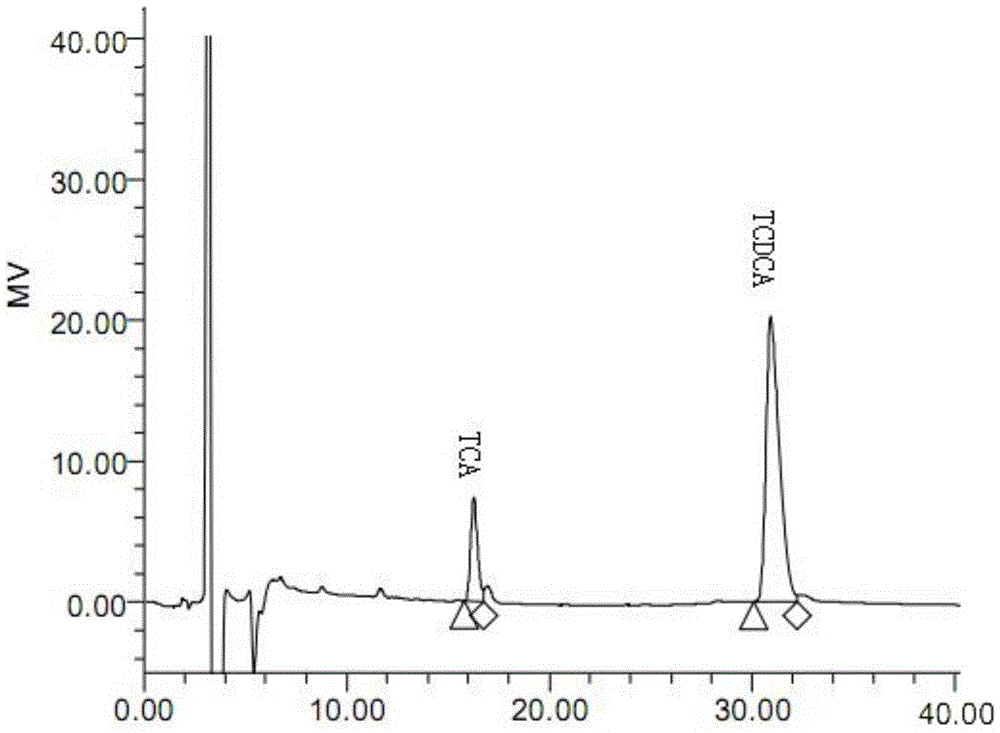

[0032] Get the fresh bile 1000g that just extracts from live chicken body, adopt high performance liquid chromatography to analyze its bile acid composition, such as figure 1 As shown, it was found that the bile acid component ratio in the bile was TCDCA:TCA=83:17.

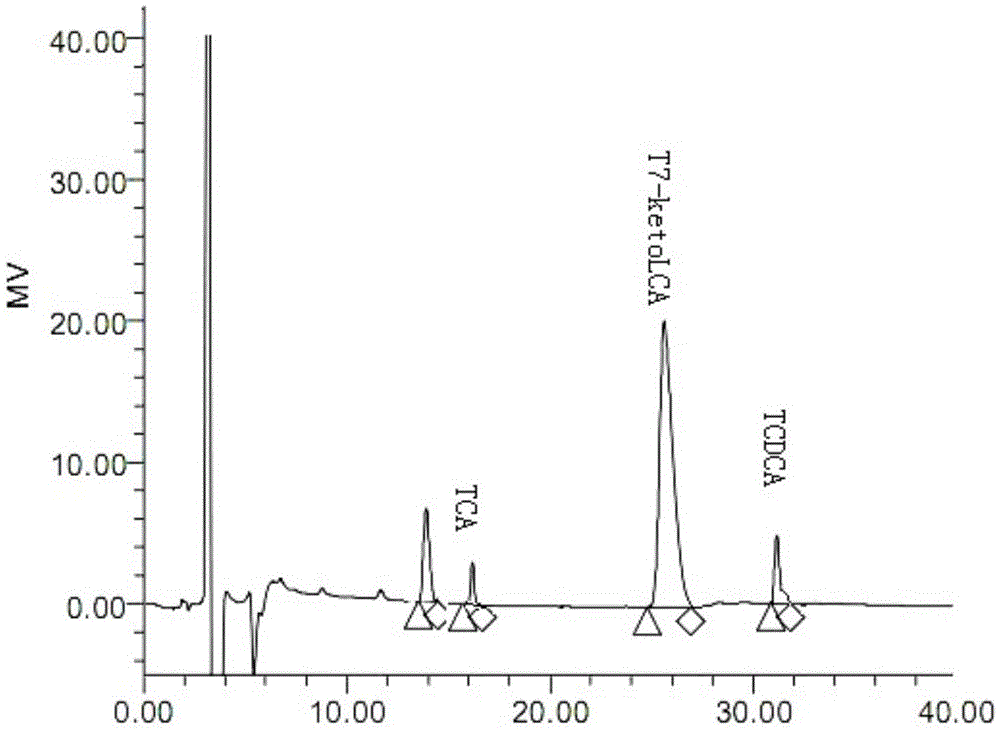

[0033] At room temperature, add 15% dilute hydrochloric acid dropwise to the chicken bile to adjust the pH to 3; then slowly stir the bile at a stirring speed of 0.02m / s, during the stirring process, according to the ratio of bile to sodium peroxide mass ratio of 1:0.015, Slowly add sodium peroxide into the bile in 10 batches within 5 hours, and add a batch of sodium peroxide about every 30 minutes. After the sodium peroxide is completely added, continue to stir and react at room temperature for 9 hours to carry out the oxidation reaction; after the oxidation reaction is completed, Such as figure 2 As shown, the high-performance liquid chromatography sampling analysis shows that the bile acid composition change ...

Embodiment 2

[0038] Take 1000g of fresh bile just extracted from live ducks, analyze its bile acid components by high performance liquid chromatography, and find that the ratio of bile acid components in the bile is TCDCA:TCA=82:18.

[0039] At room temperature, add 12% dilute hydrochloric acid dropwise to the chicken bile to adjust the pH to 4; then slowly stir the bile at a stirring speed of 0.03m / s. During the stirring process, according to the ratio of bile to sodium peroxide mass ratio of 1:0.017, Slowly add sodium peroxide into the bile in 15 batches within 5 hours, and add a batch of sodium peroxide about every 20 minutes. After the sodium peroxide is completely added, continue to stir and react at room temperature for 10 hours to carry out the oxidation reaction; after the oxidation reaction is completed, High-efficiency liquid chromatography sampling analysis draws that after the reaction is completed, the bile acid composition changes as TCDCA: T7-ketoLCA=8.8: 91.2 (because TCA ox...

Embodiment 3

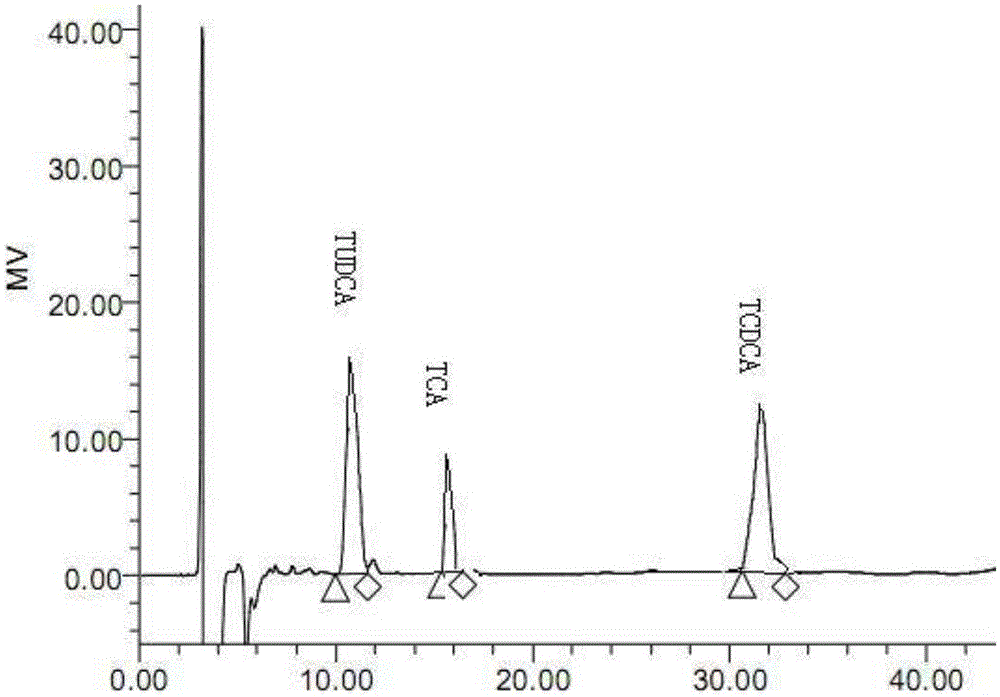

[0044] Take 1000g of fresh bile just extracted from live goose, and analyze its bile acid components by high performance liquid chromatography, and find that the ratio of bile acid components in the bile is TCDCA:TCA=83.5:16.5.

[0045] At room temperature, add 10% dilute hydrochloric acid dropwise to the chicken bile to adjust the pH to 4; then slowly stir the bile at a stirring speed of 0.03m / s. During the stirring process, according to the ratio of bile to sodium peroxide mass ratio of 1:0.017, Slowly add sodium peroxide into the bile in 15 batches within 5 hours, and add a batch of sodium peroxide about every 20 minutes. After the sodium peroxide is completely added, continue to stir and react at room temperature for 10 hours to carry out the oxidation reaction; after the oxidation reaction is completed, High-efficiency liquid chromatography sampling analysis draws that after the reaction is completed, the bile acid composition changes as TCDCA: T7-ketoLCA=8.5: 91.5 (becaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com