Manufacturing method of crib

A manufacturing method and a technology for a crib, which are applied in the field of daily necessities for babies, can solve problems such as mortise cracking, corrosion, flammability, etc., and achieve the effects of improved overall performance, uniform density distribution, and good dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The first step: design the crib style. Let's take the simplest crib as an example. The simplest crib consists of five large parts: two headboards, two side rails and a bed board.

[0017] The second step: according to the designed crib style, five foaming molds are developed based on the shapes of five large parts.

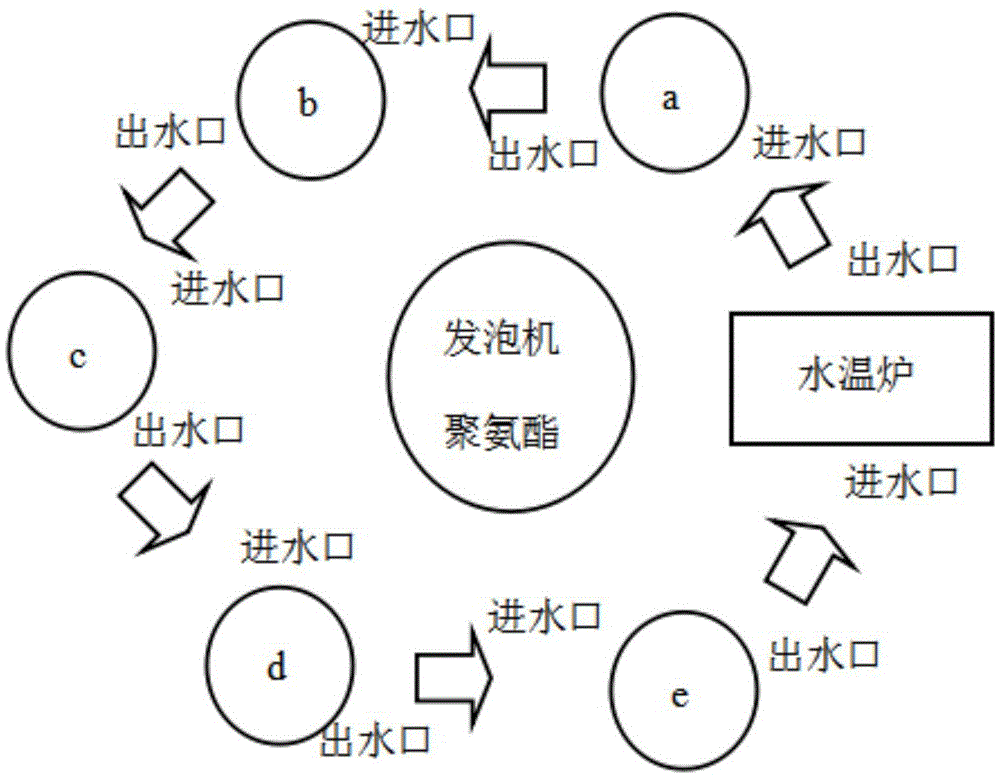

[0018] Step 3: Place the developed five foaming molds around the foaming machine in turn (for the convenience of description, they are called a.b.c.d.e in sequence) to form a circle around the foaming machine (the discharge head of the foaming machine can rotate around). Water temperature heating or electric heating technology allows the mold to preheat to about 25-35 degrees. The specific temperature is set differently depending on the indoor temperature of the factory building. In winter, the temperature should be set higher at about 35 degrees, and in summer it should be set at about 25 degrees. (When heating with water temperature, a water temperature...

Embodiment 2

[0025] In the embodiment of the present invention, plastic is raw material to make crib

[0026] The first step: design the crib style. Let's take the simplest crib as an example. The simplest crib consists of five large parts: two headboards, two side rails and a bed board.

[0027] Step 2: According to the designed crib style, five injection molds are developed based on the shapes of five large parts.

[0028] Step 3: Install the developed five foaming molds in five injection molding machines in sequence.

[0029] Step 4: Add the pellets into the barrel (each feeding should be quantitative to ensure uniform plasticization), heat and melt, (the operation process of each injection molding machine below is the same)

[0030] Step 5: Injection and pressure maintenance. The injection molding machine uses a screw to inject the molten plastic into the cavity (after the injection, keep the pressure on the molten plastic for a certain period of time).

[0031] Step 6: Keep cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com