Horseshoe-type bulk plastic composite non-woven cloth and manufacturing method and application thereof

A technology of nonwoven fabrics and manufacturing methods, which is applied in the direction of nonwoven fabrics, applications, textiles, and papermaking, and can solve the problems of high fiber fineness and high density of nonwoven fabrics, which affect the air permeability of double-layer nonwoven fabrics, and achieve Good toughness and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

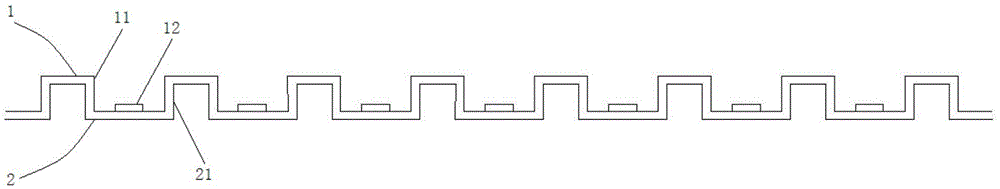

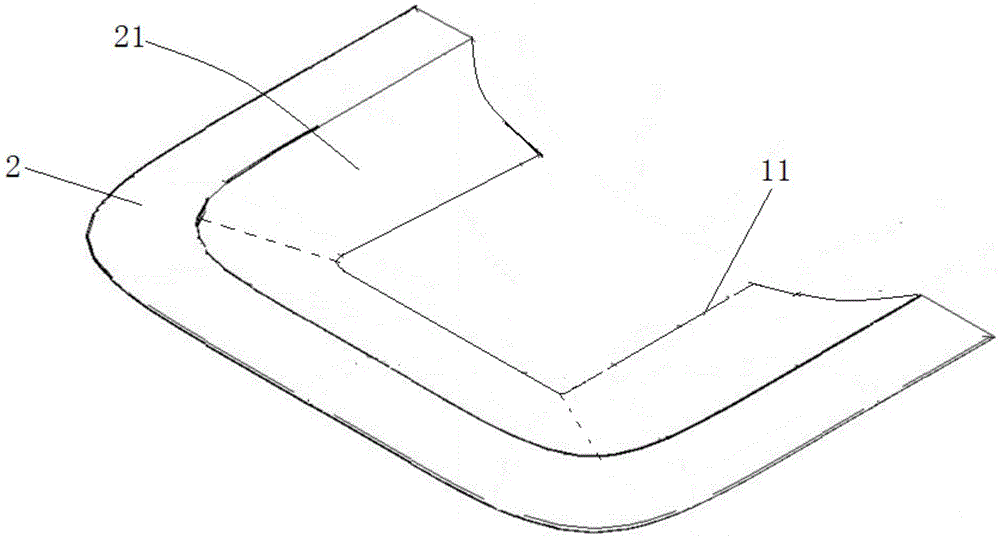

[0029] refer to figure 1 and figure 2 , a horseshoe-shaped expanded composite nonwoven fabric according to the present invention, the composite nonwoven fabric comprises: a hot-air nonwoven fabric layer or a melt-blown nonwoven fabric layer 2; a spunbonded nonwoven fabric layer 1, which is stacked on The upper surface of the hot-air nonwoven layer or the melt-blown nonwoven layer 2; the spunbonded nonwoven layer 1 is a polypropylene fiber layer; Equidistantly arranged block-shaped bulky protrusions 11, correspondingly, the surface of the hot-air nonwoven fabric layer or melt-blown non-woven fabric layer 2 is provided with grooves 21 corresponding to the block-shaped bulky protrusions 11 The bulky bulky protrusion 11 is in the shape of a horseshoe, and correspondingly, the groove 21 is in the shape of a concave horseshoe; one side of the spunbonded nonwoven fabric layer faces inward.

[0030]In addition, the block-shaped bulky protrusions 11 on the surface of the spunbond no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com