Gel particles and preparation method thereof

A technology of gel particles and silica sol, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of small sludge treatment volume and complex sludge pretreatment procedures, and achieve enhanced stability and pollution prevention. The effect of harmless treatment of mud and excellent deformation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 100 parts of acrylamide, 0.5 parts of dimethylaminoethyl methacrylate, and 0.2 parts of methylenebisacrylamide in 257 parts of deionized water to prepare an aqueous solution, add 5 parts of silica sol, 100 parts of water content 50%, oil-containing 0.5% of the sludge mass, stirred and mixed to obtain uniformly dispersed sludge slurry to be polymerized, 0.1 part of potassium ammonium persulfate and 0.1 part of sodium bisulfite were dissolved in 2 parts of deionized water to prepare an aqueous solution, and added to the sludge to be polymerized In the sludge slurry, after uniform stirring, the reaction is static at room temperature for 2 hours, and the product is cut into pieces, granulated, and sieved to obtain sludge-filled gel particles with a ratio of sludge pieces to acrylamide monomers of 1:1.

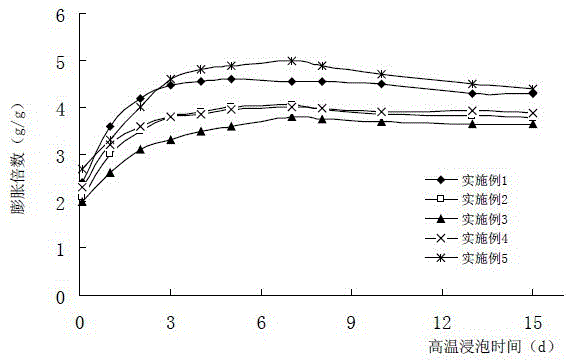

[0030] According to the evaluation method in "Q / SH10250426-2009 Pre-crosslinked Particle Profile Control Agent Technical Conditions", the expansion multiple, elastic...

Embodiment 2

[0033] Dissolve 100 parts of acrylamide, 0.5 parts of dimethylaminoethyl methacrylate, and 0.3 parts of methylene bisacrylamide in 258 parts of deionized water to prepare an aqueous solution, add 5 parts of silica sol, 150 parts of 0.5% of the sludge block, stirring and mixing to obtain uniformly dispersed sludge slurry to be polymerized, 0.2 parts of potassium ammonium persulfate and 0.2 parts of sodium bisulfite were dissolved in 4 parts of deionized water to prepare an aqueous solution, and added to the sludge to be polymerized In the sludge slurry, after being stirred evenly, the reaction is static at room temperature for 2 hours, and the product is cut into pieces, granulated, and sieved to obtain sludge-filled gel particles with a ratio of sludge pieces to acrylamide monomers of 1.5:1.

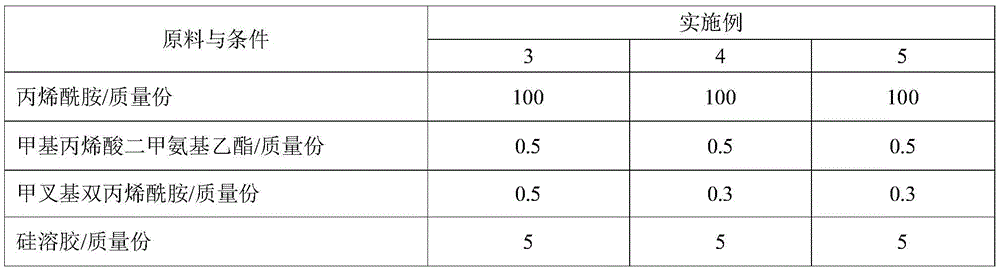

[0034] Embodiments 3-5 According to the steps of Embodiments 1 and 2, the formula and conditions are shown in Table 1.

[0035] Table 1 embodiment 3~5 gel granule synthetic formula and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com