Compound pour point-depressing viscosity reducer for high pour-point crude oil and preparation method thereof

A viscosity reducer and composite technology, applied in chemical instruments and methods, mechanical equipment, drilling compositions, etc., can solve the problems of large pour point reduction range, high freezing point, difficult transportation, etc. The effect of high viscosity reduction rate and prolonged wax cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

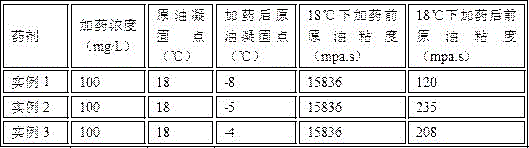

Examples

preparation example Construction

[0022] In the present invention, the specific steps of the preparation method include:

[0023] 1) Dissolve EVA and xylene at a mass ratio of 1:4 at room temperature, or dissolve EVA and diesel at a ratio of 1:4 at 60°C;

[0024] 2) Mix and react the product of the first step with dodecylbenzenesulfonic acid according to the mass ratio of 200:1 to prepare modified EVA. Among them, the product of dissolving EVA in xylene reacts at room temperature, and the product of dissolving EVA in diesel oil React at 60°C;

[0025] 3) React triethanolamine and dodecylbenzenesulfonic acid at a ratio of 4:6 at a temperature of 40°C to prepare dodecylbenzenesulfonic acid triethanolamine salt, dodecylbenzenesulfonic acid and triethanolamine compound;

[0026] 4) Add polyether BCH-1130% and lignin amphoteric surfactant to 50% of dodecylbenzenesulfonic acid triethanolamine salt, dodecylbenzenesulfonic acid and triethanolamine compound prepared in 3) 10% and polyether TEF323210% were mixed and ...

Embodiment 1

[0034] Add 320g of xylene to a 500mL four-necked bottle with a thermometer and a stirrer, then add 80g of EVA, start the stirrer to stir and dissolve, and drop 1.2g-2g of dodecylbenzenesulfonic acid after it is completely dissolved, and stir evenly. React at room temperature for 24 hours to obtain a light yellow viscous liquid—modified EVA.

[0035] Add 120g of triethanolamine, polyether BCH-1160g, lignin amphoteric surfactant 20g, polyether TEF323220g into a 500mL four-necked bottle with a thermometer, agitator and condenser in sequence, start the agitator, and add twelve Alkylbenzenesulfonic acid 180g, temperature controlled within 40°C, stirred for 4h to obtain a light brown viscous liquid mixed agent.

[0036] Add 120 g of the above-mentioned modified EVA and 280 g of the above-mentioned mixed agent into a 500 mL four-necked bottle equipped with a thermometer and a stirrer, and stir at a constant temperature of 60 ° C for 3 hours to obtain a light brown composite pour poin...

Embodiment 2

[0038] Add 320g of diesel oil into a 500mL four-necked bottle with a thermometer and agitator, add 80g of EVA, start the agitator to stir, raise the temperature to 60°C and wait until it is completely dissolved, add 2g of dodecylbenzenesulfonic acid dropwise, stir evenly, at 60°C After 8 hours of reaction, a yellow viscous liquid—modified EVA was obtained.

[0039] Add 160g of triethanolamine to a 500mL four-neck bottle equipped with a thermometer, agitator and condenser tube, start to add dodecylbenzenesulfonic acid dropwise, and control the dropping speed during the addition of 240g to keep the temperature at 40°C Within 2 hours after the dropwise addition of the reagent, a light yellow translucent viscous liquid—dodecylbenzenesulfonic acid triethanolamine salt, dodecylbenzenesulfonic acid, triethanolamine compound was obtained.

[0040] Add 200g of the above-mentioned modified EVA to a 500mL four-necked bottle with a thermometer and a stirrer, and dodecylbenzenesulfonic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com