Green separating process for components of lignocellulose

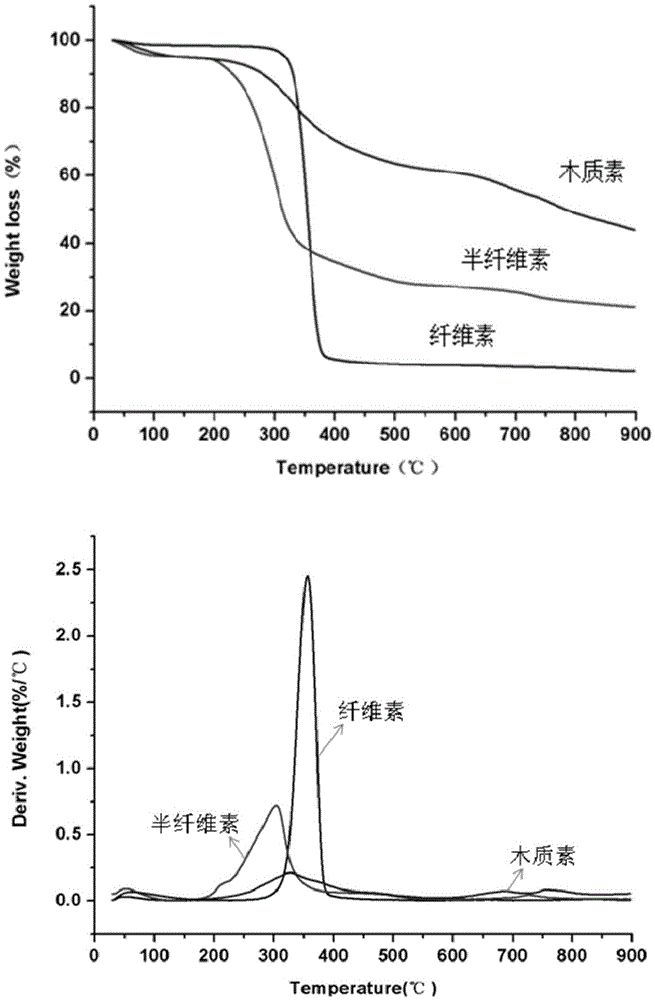

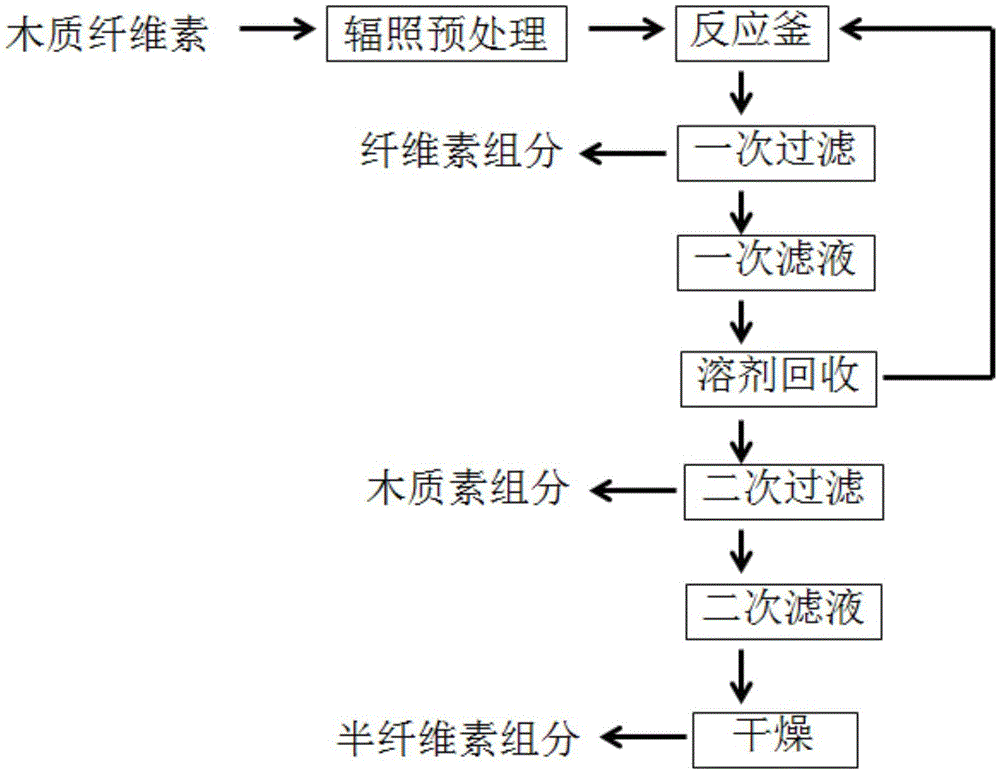

A lignocellulosic and green process technology, which is applied in the high-value utilization of biomass resources and the field of biochemical industry, can solve the problems of waste acid or waste lye discharge, large water consumption, secondary pollution, etc., and achieve low energy consumption and high yield. The effect of high yield and purity, simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the following specific examples, which are only used to illustrate the present invention but not to limit the scope of the present invention.

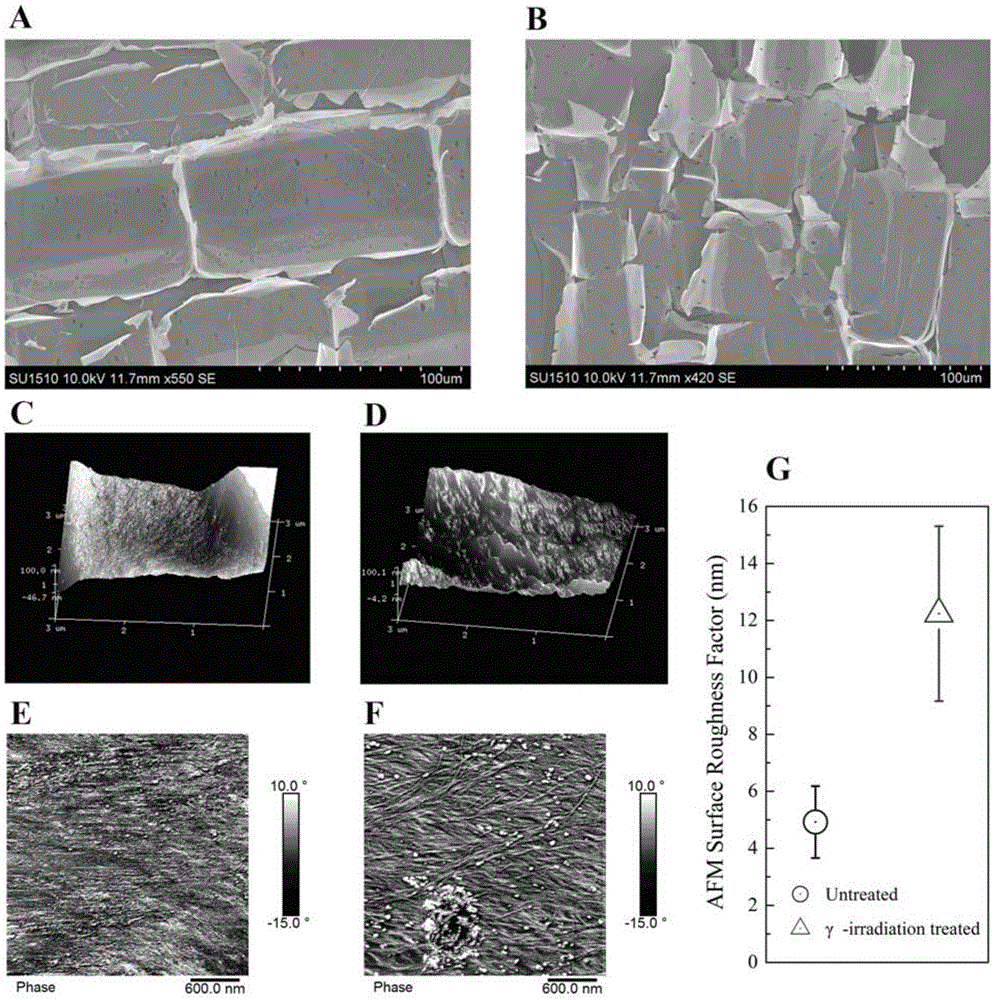

[0027] Case 1:

[0028] Put the reeds into the irradiation box and irradiate at 500kGy. Weigh 1.0 g of irradiated crushed reed powder into a 50 mL reactor, add 10 mL of tetrahydrofuran / water (volume ratio 4:6) mixed solution, and react at 170°C for 3 h. After the reaction, cool down, rinse the residual residue in the reaction kettle with a mixed solution of 1 volume of tetrahydrofuran / water (volume ratio: 4:6), filter once, dry the filter cake at 105°C for 2 hours, and weigh to obtain the cellulose component 0.56g, the detected glucose content is 91.7%. Recover THF in the filtrate, the recovery rate is 91%, and can be reused. After secondary filtration, the filter cake was dried at 105° C. for 4 hours, and weighed to obtain 0.21 g of lignin component with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com