A method for preparing high bulk density flavored nucleotide disodium mixed crystals

A technology of nucleotide disodium and mixed crystals, which is applied in the field of preparation of high bulk density flavored nucleotide disodium mixed crystals, which can solve the problem of not being able to meet the requirements for the preparation of high-quality umami flavor agents and not strictly controlling the nucleation of crystals , product crystals are finely broken, etc., to achieve the effect of green and friendly solvent system, solving the difficulty of GMP crystallization, and shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Take 7.11 g of crude disodium inosinate and 7.89 g of amorphous disodium guanylate, add them to 250 ml of pure water, keep the solution at 25°C, start stirring at 100 rpm to dissolve it. Solid sodium hydroxide was added to adjust the pH of the aqueous I+G solution to 7.5.

[0049] 2) Adjust the stirring to 200rpm, add 75ml of absolute ethanol (V=30%V) within 30min 水 ), after mixing evenly, add 0.075 g of I+G seed crystal (w=0.5% I+G crude product), and grow the crystal for 20 minutes.

[0050] 3) Continue to add 425ml of ethanol dropwise, the time for adding the first 50ml is 2h, and the time for adding the last 375ml is 1h.

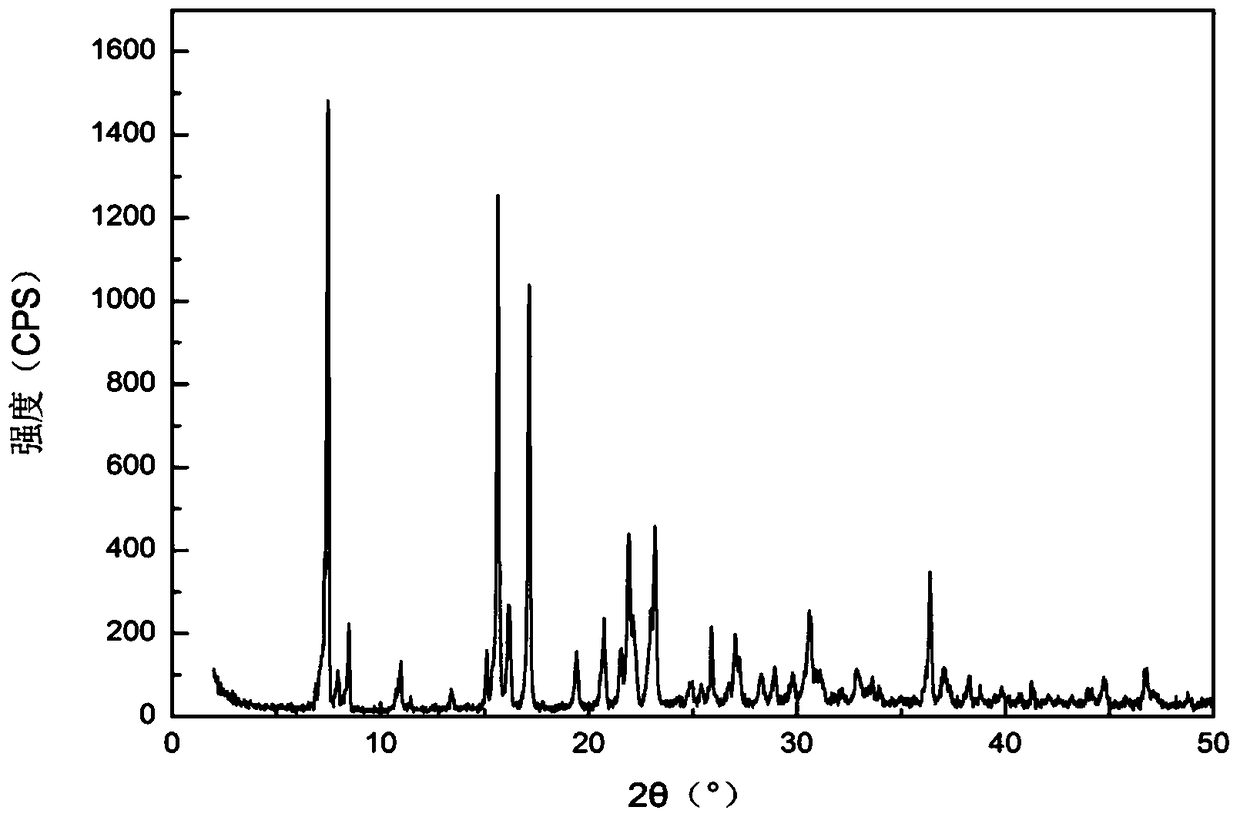

[0051] 4) Suction filtration, washing the filter cake with 95% ethanol, and drying at normal temperature and pressure for 1 hour. 12.2 g of the I+G mixed crystal product was obtained with a yield of 80.9%. After measurement, the bulk density of the product is 0.81g / ml. The detection result of the Malvern particle size analyzer is d(50)=360 ...

Embodiment 2

[0054] 1) Take 30.45g of crude disodium inosinate and 32.05g of crude disodium guanylate, add them to 250ml of pure water, keep the solution at 45°C, start stirring at 600rpm to dissolve it. Solid sodium hydroxide was added to adjust the pH of the aqueous I+G solution to 8.5.

[0055] 2) Adjust and stir at 400rpm, add 25ml of anhydrous methanol (V=10%V) within 30min 水 ), after mixing evenly, add 6.25 g of I+G seed crystals (w=0.5% I+G crude product), and grow the crystals for 30 minutes.

[0056] 3) Continue to add 225ml of methanol dropwise, the time for adding the first 150ml is 3h, and the time for adding the last 75ml is 1h.

[0057] 4) Suction filtration, the filter cake was washed with 95% ethanol, and dried at normal temperature and pressure for 3 hours to obtain 64.76 g of I+G mixed crystal product with a yield of 94.2%. After measurement, the bulk density of the product is 0.77g / ml. The detection result of the Malvern particle size analyzer was d(50)=244 μm.

[00...

Embodiment 3

[0060] 1) Take 18.75g of crude disodium inosinate and 18.75g of crude disodium guanylate, add them into 250ml of pure water, keep the solution at 35°C, start stirring at 300rpm to dissolve it. Solid sodium hydroxide was added to adjust the pH of the aqueous I+G solution to 8.0.

[0061] 2) Add 65ml of absolute ethanol (V=26%V) within 30min 水 ), after mixing evenly, add 2.0 g of I+G seed crystals (w=5.3% I+G crude product), and grow the crystals for 30 minutes.

[0062] 3) Continue to add 255ml of ethanol dropwise, the time for adding the first 65ml is 2h, and the time for adding the last 115ml is 2h.

[0063] 4) Suction filtration, the filter cake was washed with 95% ethanol, and dried at normal temperature and pressure for 1 h to obtain 37.95 g of I+G mixed crystal product with a yield of 96.1%. After measurement, the bulk density of the product is 0.86g / ml. The detection result of the Malvern particle size analyzer was d(50)=419 μm.

[0064] The product appearance obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com