Catalyst for preparation of methanol by carbon dioxide hydrogenation

A carbon dioxide and catalyst technology, applied in the field of catalysts for hydrogenation of carbon dioxide to methanol, can solve the problem of low catalyst activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Catalyst preparation

[0036] Mix 500 grams of palladium nitrate aqueous solution (containing 25 grams of palladium) with 975 grams of 100-120 mesh ZrO 2 The powders were mixed, allowed to stand at room temperature for 12 hours, dried at 110° C. for 12 hours, calcined at 500° C. in an air atmosphere for 4 hours, and cooled naturally to obtain a catalyst precursor. Pressing, crushing and sieving into 40-60 mesh particles under 16MPa, and then reducing at 200° C. for 2 hours in a hydrogen-nitrogen mixed atmosphere with a hydrogen content of 5v% to obtain a catalyst.

[0037] Methanol synthesis

[0038] The synthesis of methanol is carried out in a fixed bed reactor. Methanol synthesis reaction conditions: reaction temperature 270°C, reaction pressure 4MPa, hydrogen:carbon dioxide:nitrogen volume ratio 60:20:20, GHSV=15000mL / (h·g).

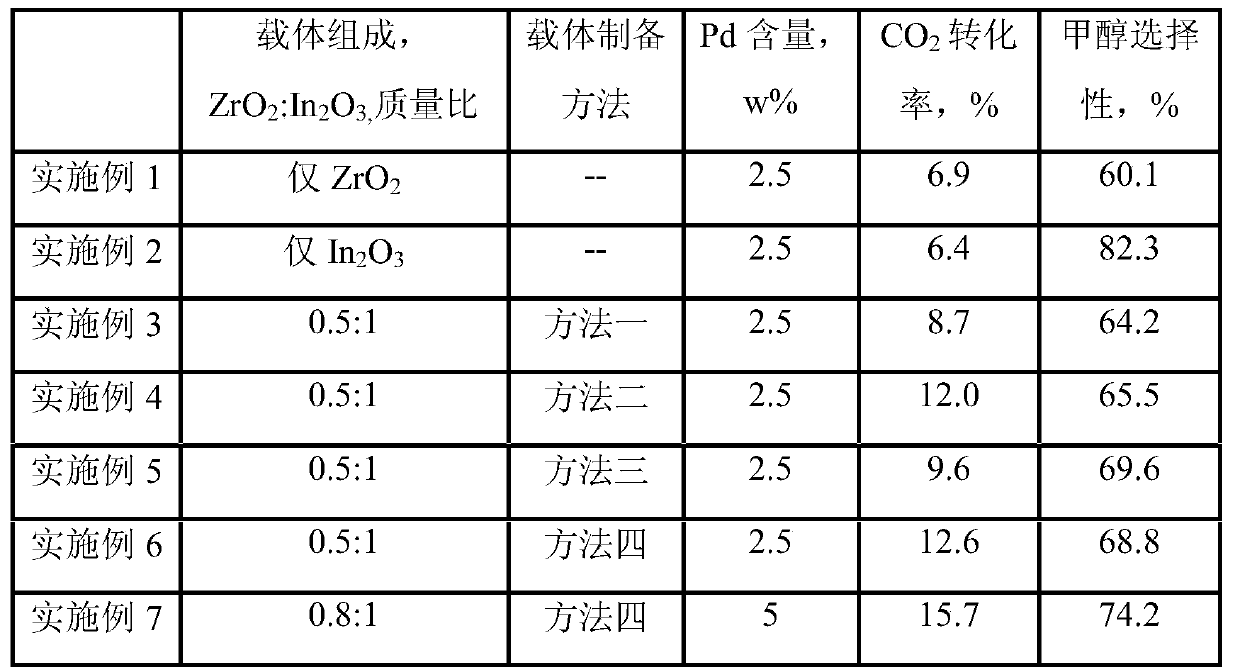

[0039] For the convenience of comparison, the catalyst composition, preparation process and methanol synthesis reaction results are listed...

Embodiment 2

[0041] Catalyst preparation

[0042] Mix 500 grams of palladium nitrate aqueous solution (containing 25 grams of palladium) with 975 grams of 100-120 mesh In 2 o 3 The powders were mixed, allowed to stand at room temperature for 12 hours, dried at 110° C. for 12 hours, calcined at 500° C. in an air atmosphere for 4 hours, and cooled naturally to obtain a catalyst precursor. Pressing, crushing and sieving into 40-60 mesh particles under 16MPa, and then reducing at 200° C. for 2 hours in a hydrogen-nitrogen mixed atmosphere with a hydrogen content of 5v% to obtain a catalyst.

[0043] Methanol synthesis

[0044] The synthesis of methanol is carried out in a fixed bed reactor. Methanol synthesis reaction conditions: reaction temperature 270°C, reaction pressure 4MPa, hydrogen:carbon dioxide:nitrogen volume ratio 60:20:20, GHSV=15000mL / (h·g).

[0045] For the convenience of comparison, the catalyst composition, preparation process and methanol synthesis reaction results are list...

Embodiment 3

[0047] Vector preparation

[0048] 100~120 mesh ZrO 2 Powder and 100-120 mesh In 2 o 3 The powder is mixed as a carrier in a mass ratio of 0.5:1.

[0049] Catalyst preparation

[0050] Mix 500 grams of palladium nitrate aqueous solution (containing 25 grams of palladium) with 975 grams of carrier, let stand at room temperature for 12 hours, dry at 110°C for 12 hours, and then roast at 500°C in an air atmosphere for 4 hours, and cool naturally to obtain a catalyst precursor . Pressing, crushing and sieving into 40-60 mesh particles under 16MPa, and then reducing at 200° C. for 2 hours in a hydrogen-nitrogen mixed atmosphere with a hydrogen content of 5v% to obtain a catalyst.

[0051] Methanol synthesis

[0052] The synthesis of methanol is carried out in a fixed bed reactor. Methanol synthesis reaction conditions: reaction temperature 270°C, reaction pressure 4MPa, hydrogen:carbon dioxide:nitrogen volume ratio 60:20:20, GHSV=15000mL / (h·g).

[0053] For the convenience ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com