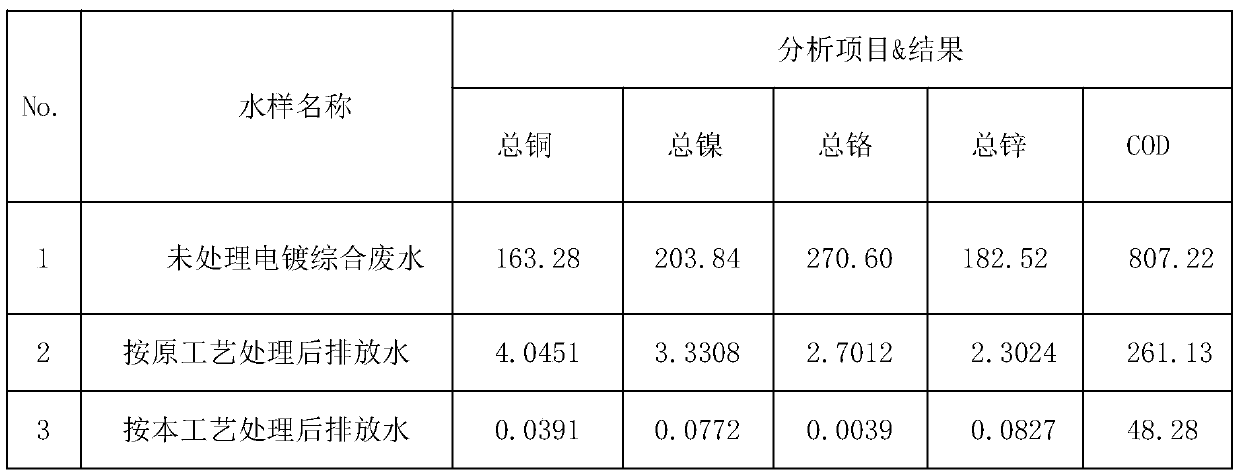

Processing technology for electroplating synthetic wastewater

A comprehensive electroplating and treatment process technology, applied in the fields of metallurgical wastewater treatment, special compound water treatment, multi-stage water treatment, etc., can solve the problems that the treatment of heavy metals is not easy to meet the standard, and the cost is high. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

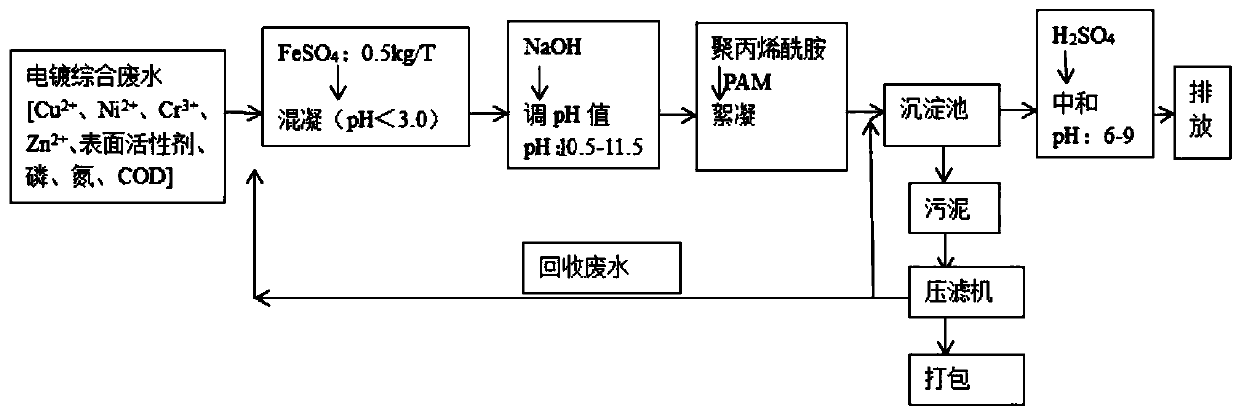

[0031] A process for treating comprehensive electroplating wastewater, the specific steps are:

[0032] (1) network breaking: add sulfuric acid to the comprehensive electroplating wastewater, adjust the pH value to 2, and stir for 30min; then add a complex breaking agent, and the addition amount is 1.0Kg per ton of waste water, and the reaction is 30min;

[0033] (2) coagulation: adding ferrous sulfate to the waste water to carry out coagulation reaction, the dosage is 0.5Kg per ton of waste water, and the reaction is 30min;

[0034] (3) Adjust pH value: adjust the pH value of wastewater to 11 with NaOH;

[0035] (4) flocculation: add polyacrylamide for flocculation, and the addition amount is 100g per ton of water;

[0036] (5) Precipitation treatment for 2h, after solid-liquid separation, the supernatant liquid is the first-level effluent;

[0037] (6) network breaking: add a network breaking agent in the primary effluent, the amount of addition is 0.5Kg per ton of waste w...

Embodiment 2

[0049] A process for treating comprehensive electroplating wastewater, the specific steps are:

[0050] (1) network breaking: add sulfuric acid to the comprehensive electroplating wastewater, adjust the pH value to 3, and stir for 30min; then add a network breaking agent, and the addition amount is 2.0Kg per ton of waste water, and the reaction is 30min;

[0051] (2) coagulation: adding ferrous sulfate to the waste water to carry out coagulation reaction, the dosage is 0.5Kg per ton of waste water, and the reaction is 30min;

[0052] (3) Adjust pH value: adjust the pH value of wastewater to 10.5 with NaOH;

[0053] (4) flocculation: add polyacrylamide for flocculation, and the addition amount is 200g per ton of water;

[0054] (5) Precipitation treatment for 1h, after solid-liquid separation, the supernatant liquid is the first-level effluent;

[0055] (6) network breaking: adding a network breaking agent in the primary effluent to break the network, the addition amount is 0.5...

Embodiment 3

[0062] A process for treating comprehensive electroplating wastewater, the specific steps are:

[0063] (1) network breaking: add sulfuric acid in the comprehensive electroplating wastewater, adjust the pH value to 2, and stir for 30min; then add Na2S, the addition amount is 2.0Kg per ton of wastewater, and the reaction is 40min;

[0064] (2) coagulation: adding ferrous sulfate to the waste water to carry out coagulation reaction, the dosage is 0.5Kg per ton of waste water, and the reaction is 30min;

[0065] (3) Adjust pH value: adjust the pH value of wastewater to 11 with NaOH;

[0066] (4) flocculation: add polyacrylamide for flocculation, and the addition amount is 150g per ton of water;

[0067] (5) Precipitation treatment for 2h, after solid-liquid separation, the supernatant liquid is the first-level effluent;

[0068] (6) network breaking: adding a network breaking agent in the primary effluent to break the network, the addition amount is 0.5Kg per ton of waste water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com