Method for preparing high-purity ricinus oil according to chromatographic separation

A castor oil, high-purity technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problem of no high-purity castor oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

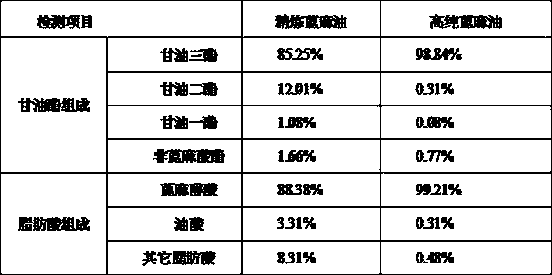

[0025] The preparation of embodiment 1 high-purity castor oil

[0026] Under normal temperature and pressure, 1 kg of coarse-pore 100-200 mesh silica gel, n-hexane, ethyl acetate volume ratio of 6:1 eluent was stirred into a homogenate and then added to the chromatography column. After the silica gel was solidified, the buffer was added Quartz sand, 100g crude castor oil was dissolved in 300ml eluent, stirred evenly, added to the chromatography column, and eluted for 30min; the eluent with a volume ratio of n-hexane and ethyl acetate of 4:1 was eluted for 90min; The column pressure is 0.5MPa, and the eluent with a volume ratio of n-hexane and ethyl acetate of 1:1 is eluted for 30 minutes, analyzed by TLC, and the iodine cylinder is used for color development, and high-purity castor oil is collected. Half of the solution volume is heated at 80°C. Wash twice with salt water, dry the oil layer with anhydrous sodium sulfate, filter, and distill under reduced pressure to obtain 66 ...

Embodiment 2

[0030] The preparation of embodiment 2 high-purity castor oil

[0031] Under normal temperature and pressure, 1 kg of coarse-pore 100-200 mesh silica gel and n-hexane, ethyl acetate, acetic acid volume ratio of 6:1:0.1 eluent was stirred into a homogenate and added to the chromatography column, and the silica gel was solidified Finally, add buffering agent quartz sand, dissolve 100g crude product castor oil in 300ml eluent, stir evenly, add in the chromatographic column, and elute for 30min; the volume ratio of n-hexane, ethyl acetate and acetic acid is 7:3 : 0.1 eluent elution 90min; pressure 0.5MPa, n-hexane, ethyl acetate and acetic acid volume ratio of 1:1:0.1 eluent elution 30min, TLC analysis, iodine cylinder color development, collection of high purity castor oil, half of the volume of the solution was washed twice with hot brine at 80°C, the oil layer was dried with anhydrous sodium sulfate, filtered, and distilled under reduced pressure to obtain 53 g of castor oil, w...

Embodiment 3

[0032] The preparation of embodiment 3 high-purity castor oil

[0033] 1 kg of coarse-pore 100-200 mesh silica gel and V petroleum ether: V ethyl acetate = 4:1 eluent were stirred into a homogenate and then added to the chromatography column. After the silica gel was solidified, the buffer quartz sand was added, and 100g Crude castor oil was dissolved in 300ml eluent, stirred evenly and added to the chromatographic column, chromatographic separation, TLC analysis, iodine cylinder color development, high-purity castor oil was collected, vacuum distillation, and the obtained oil was added to 3g of Clay clay and 3g of gac, decolouring under 90 ℃ of temperature vacuum degree-0.098MPa 2 hours, the high-purity castor oil after distillation and decolouring is press-filtered under 0.5MPa with the press filter that macromolecule precision microporous membrane is housed, thereby Obtain 59g of high-purity castor oil, the yield is 59%. After testing, the castor oil fatty acid contains ric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com