Air-liquid dual injection type airlift loop reactor

A loop reactor, double-spray technology, applied in the direction of bioreactor/fermenter combination, special-purpose bioreactor/fermenter, biochemical equipment, etc., can solve the problem that the content of substrate, nutrient and oxygen cannot be kept consistent , poor gas-liquid separation effect, poor mixing contact between phases, etc., to achieve large-scale industrial production and application, low equipment cost, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings.

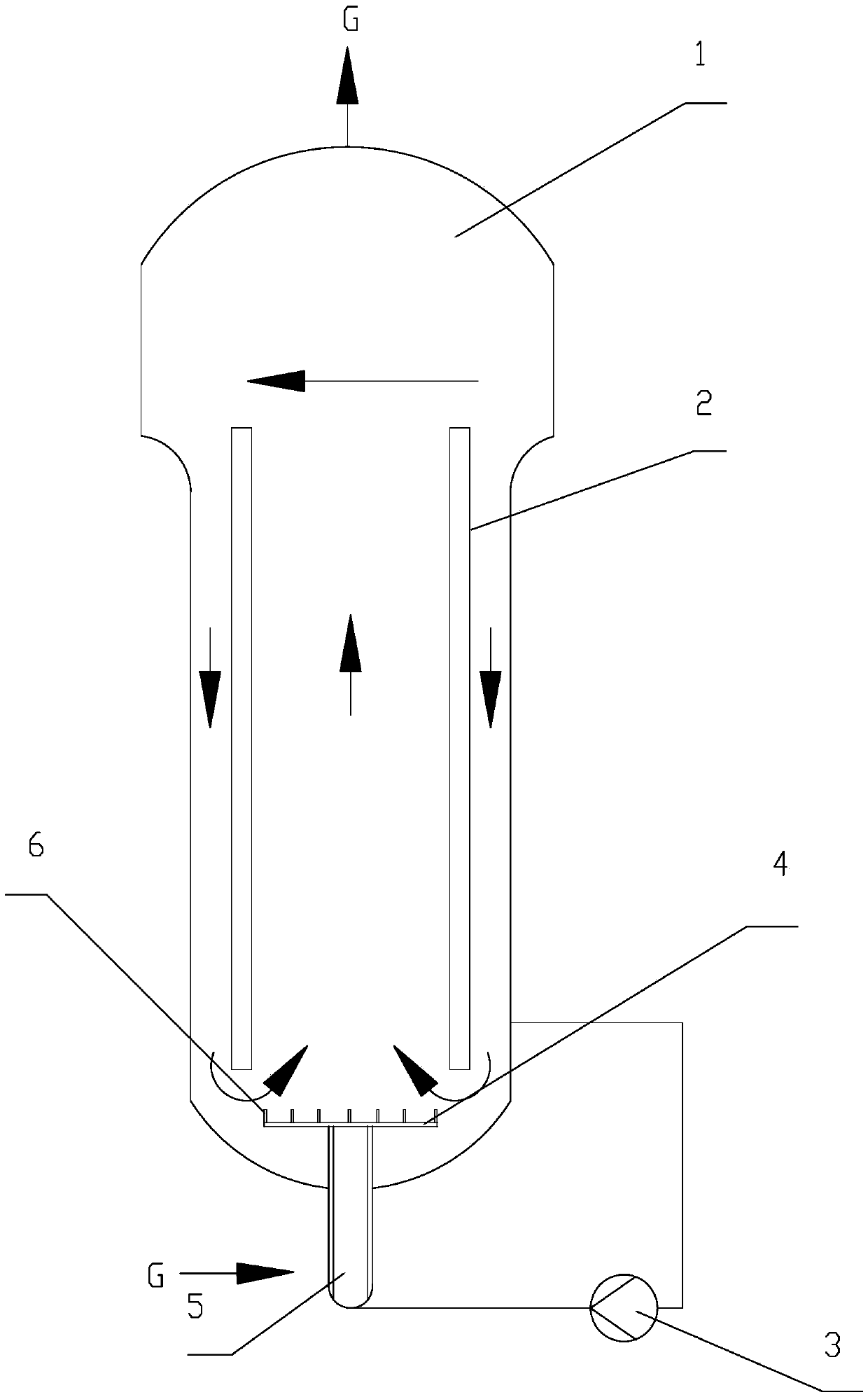

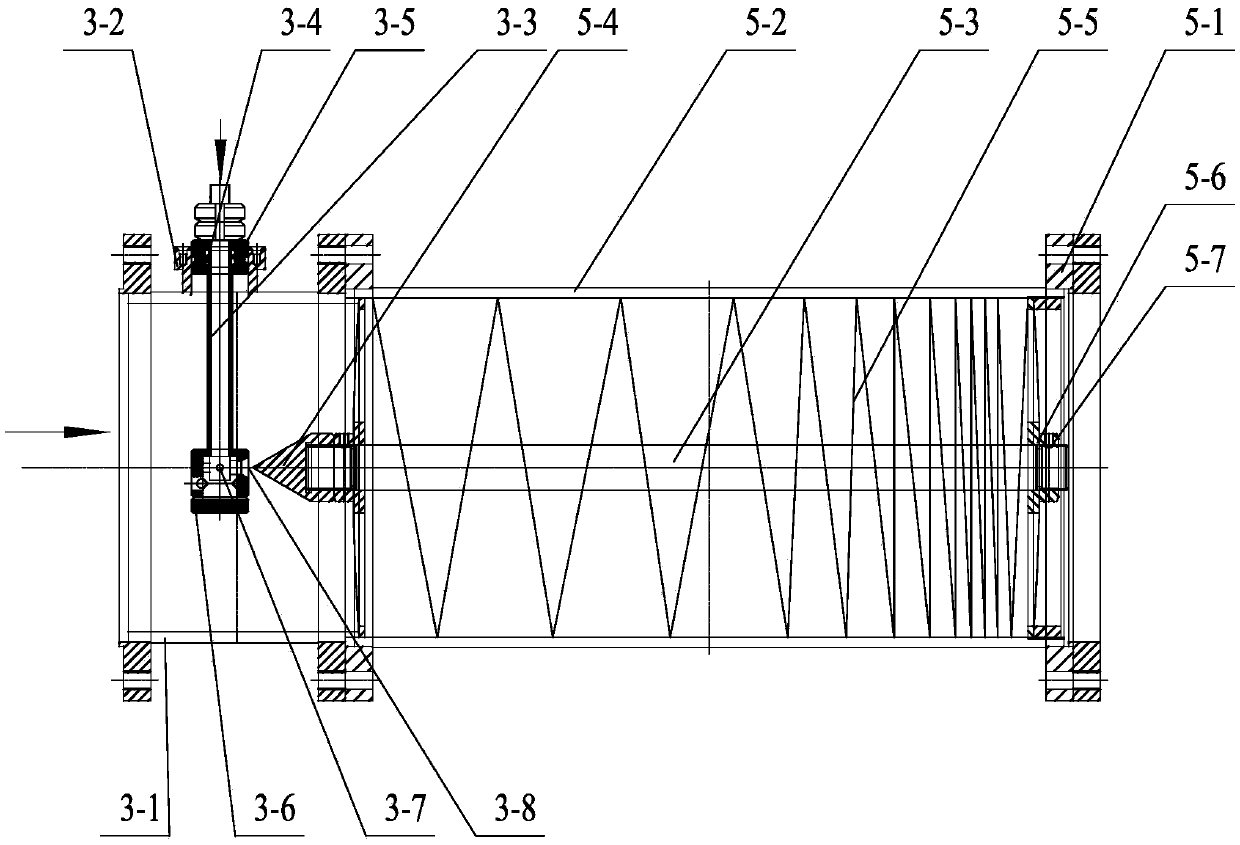

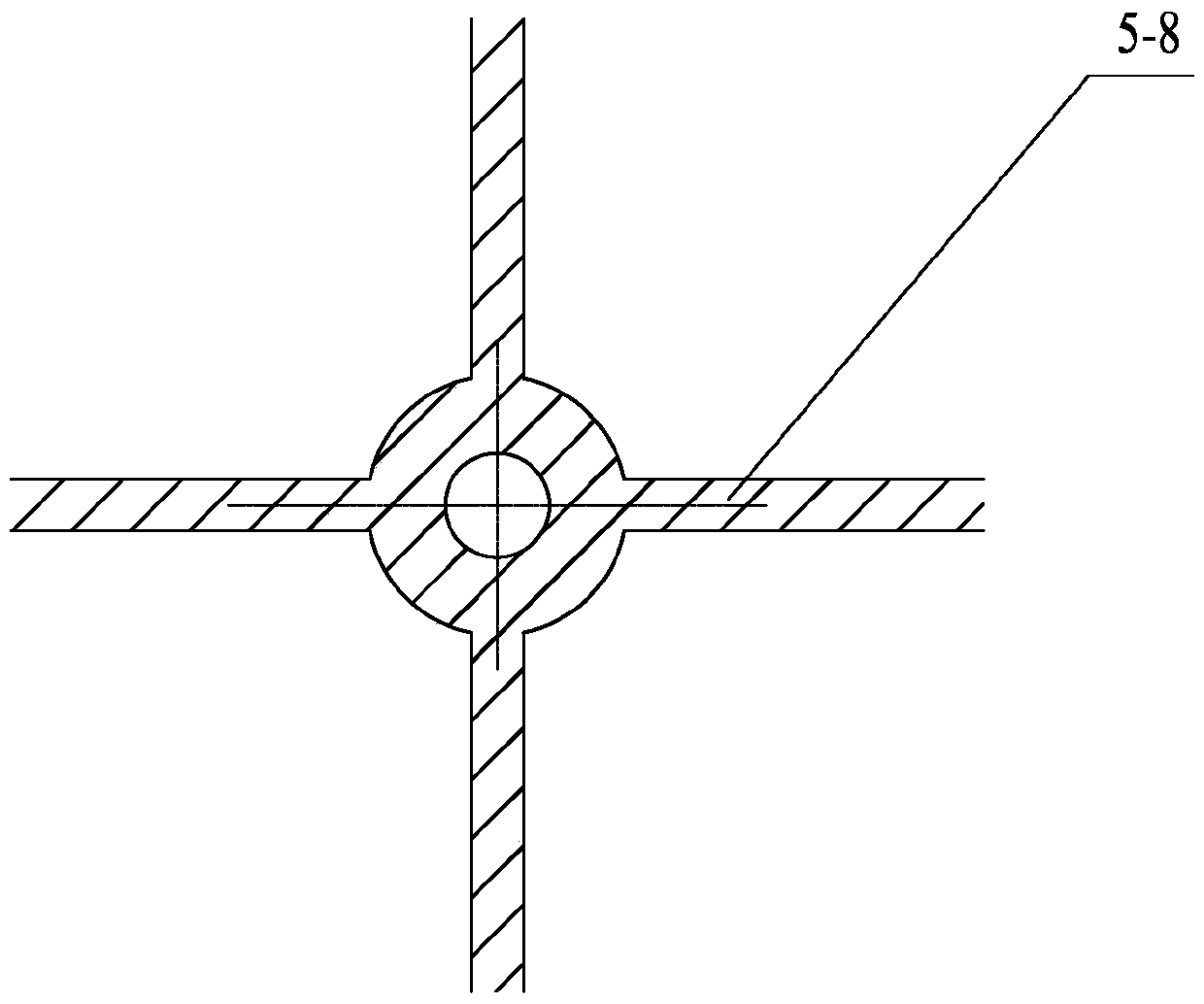

[0026] Such as Figure 1 to Figure 4 As shown: the gas-liquid double-jet airlift loop reactor includes a fermenter 1, a guide tube 2, a fermentation liquid pump 3, a distribution pipe 4, a static spiral cutting device 5, a spray hole 6, and an air filling head 3- 1. Pipe seat 3-2, air guide pipe 3-3, sealing ring 3-4, sealing block 3-5, throttle seat 3-6, throttle valve core 3-7, air hole 3-8, flange 5 -1. Cutting tube 5-2, mandrel 5-3, guide cone 5-4, cutting piece 5-5, briquetting block 5-6, lock nut 5-7, blade 5-8, etc.

[0027] Such as figure 1 As shown, the gas-liquid double-spray air-lift circulation reactor of the present invention includes a fermenter 1, the material of the fermenter 1 is SUS316L, and the nominal volume is 500L; a guide tube 2 is set in the fermenter 1 , the guide tube 2 adopts an existing commercially available molybdenum guide tube; the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com