Powder metallurgy brake pad friction material and preparation method thereof

A technology for brake pads and friction materials, which is applied in the field of powder metallurgy materials, can solve the problems of high density and hardness of friction materials, poor stability of friction coefficient, and various alloy components, and achieves low wear, good matching, and improved The effect of antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

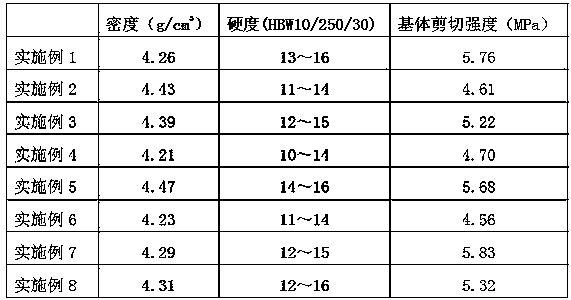

Embodiment 1

[0036] The preparation method of the powder metallurgy brake pad friction material of this embodiment includes the following specific steps:

[0037] A. Use an electronic scale to weigh the raw materials. The composition and mass percentage of the raw materials are: copper powder: 56%, chromium-iron alloy powder: 29%, flake graphite: 10%, silicon carbide: 5%. The composition and mass percentage of ferrochrome powder are: chromium: 40%, carbon: 3%, silicon: 1.5%, and the balance is iron.

[0038] B. Use a coulter-type high-speed mixer to fully mix the raw materials. In order to improve the uniformity of the mixing of the materials and prevent the segregation of the raw materials, 0.5% of the total mass of the raw materials is added as a binder during mixing. The mixing time is 30 min.

[0039] C. Use a special powder metallurgy press to press the raw materials into shape. The pressing pressure is 16 MPa.

[0040] D. Adopt a bell-type pressure sintering furnace capable of raising te...

Embodiment 2

[0043] The preparation method of the powder metallurgy brake pad friction material of this embodiment includes the following specific steps:

[0044] A. Use an electronic scale to weigh the raw materials. The components of the raw materials and their mass percentages are: copper powder: 47%, ferrochrome powder: 33%, flake graphite: 15%, silicon carbide: 5%. The composition and mass percentage of ferrochrome powder are: chromium: 35%, carbon: 4%, silicon: 1%, and the balance is iron.

[0045] B. Use a coulter-type high-speed mixer to fully mix the raw materials. The mixing time is 35 min.

[0046] C. Use a special powder metallurgy press to press the raw materials into shape. The pressing pressure is 18 MPa.

[0047] D. Adopt a bell-type pressure sintering furnace capable of raising temperature step by step for pressure sintering. The sintering temperature is 1000℃ and the sintering time is 11h. During sintering, in order to improve the compactness and bonding strength of the mater...

Embodiment 3

[0050] The preparation method of the powder metallurgy brake pad friction material of this embodiment is the same as that of embodiment 1, except for the following:

[0051] In step A, the components of the raw materials and their mass percentages are: copper powder: 50%, ferrochrome powder: 33%, flake graphite: 11%, and silicon carbide: 6%.

[0052] In step B, the adhesive is alcohol which accounts for 0.8% of the total mass of the raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com