Method for preparing cellulose-reinforced nanocomposite fiber film by electrospinning

A nano-composite fiber and electrospinning technology, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problems of difficult film formation, poor thermal stability and poor compatibility of PMMA fiber films, and achieve improved Effects of mechanical properties, thermal properties, and excellent usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Embodiment 1: The method for preparing cellulose-reinforced nanocomposite fiber film by electrospinning in this embodiment is carried out according to the following steps:

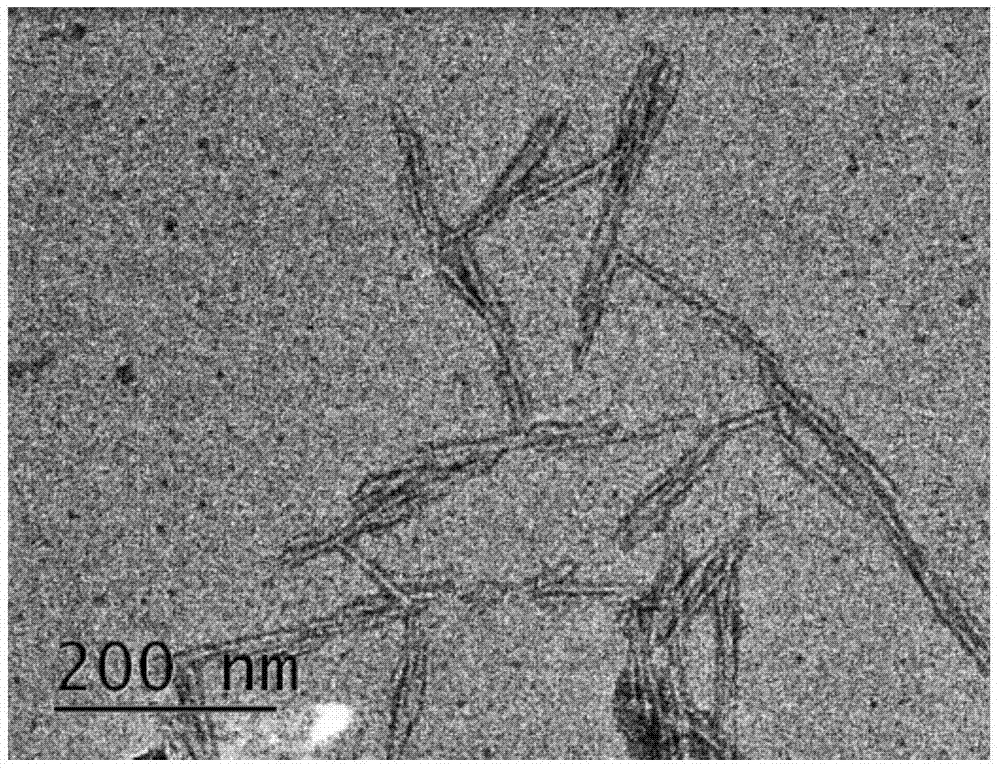

[0030] 1. Mix 20-40g of microcrystalline cellulose and 160-400g of sulfuric acid solution, stir for 1-2 hours to obtain a mixed solution, add 10-20 times the mass of the mixed solution to dilute with deionized water to obtain a suspension, and place the suspension at 4 Stand still at ℃ for 24 hours, remove the settled CNC in the lower layer, add deionized water and centrifuge for 10-20 minutes, repeat the washing for 3 times to obtain a weakly acidic suspension, and then place the weakly acidic suspension in a dialysis bag for dialysis , until the pH value is 7, and then ultrasonically disperse for 5 to 10 minutes to obtain a CNC aqueous suspension;

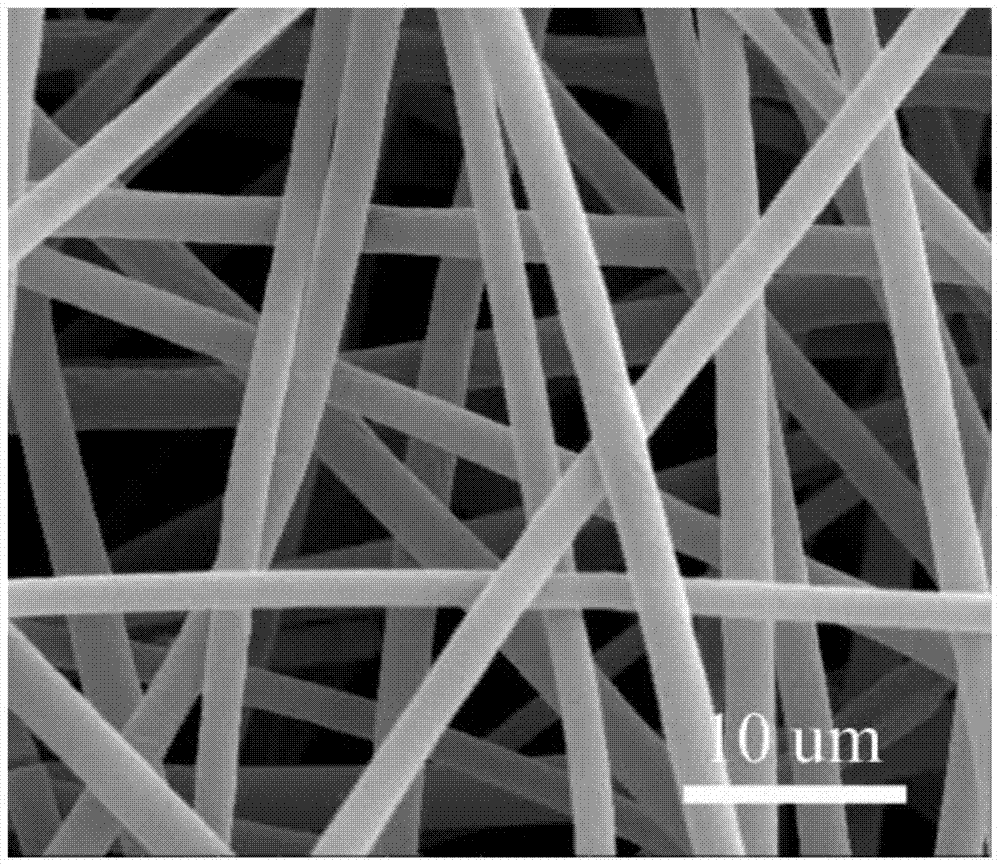

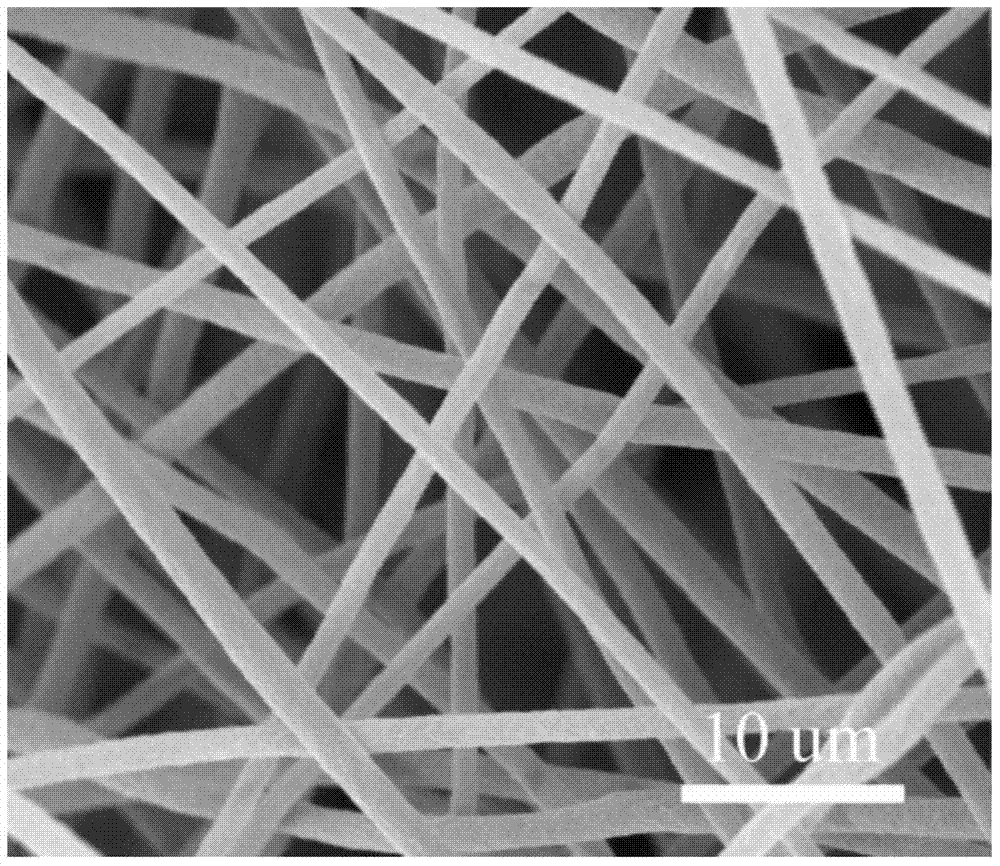

[0031] 2. Put 200-300ml of CNC aqueous suspension into a flask, add an equal volume of dimethylformamide (DMF) and stir evenly to obtain CNC / H 2 O / DM...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass concentration of the sulfuric acid solution in step 1 is 64%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036]Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in step 1, deionized water with a mass of 12 to 18 times the mass of the mixed solution is added for dilution. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com