Multistage cutting and grinding blow-down pump

A sewage pump and grinding technology, which is applied in the direction of pumps, pump devices, pump components, etc., can solve the problems that affect the normal operation and service life of the sewage pump, the blades or the main shaft are easy to be entangled, and the cutting effect is poor, so as to improve the cutting mill. crushing capacity, improve the quality of cutting and grinding, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

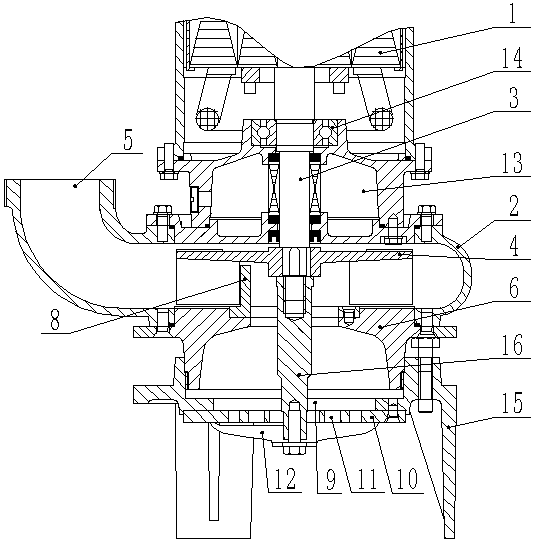

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0026] like figure 1 As shown, a multi-stage cutting and grinding sewage pump includes a pump body 1 and a pump casing 2 arranged on the lower side of the pump body 1. The pump body 1 is axially fixed with a pump shaft 3, and the pump body 1 is fixed axially. The lower end of the pump shaft 3 protrudes from the pump body 1 and the lower end of the pump shaft 3 is fixedly connected with the impeller 4. Here, the connection form between the impeller 4 and the pump shaft 3 is a key connection, and the impeller 4 is located at the In the cavity of the pump casing 2, a water outlet 5 is arranged on one side of the pump casing 2.

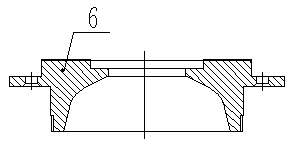

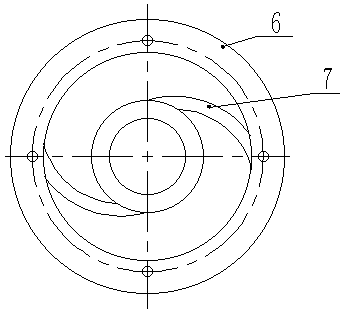

[0027] The lower end of the pump casing 2 is fixedly connected with a blade fixing frame 6, and the blade fixing frame 6 and the pump casing 2 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com