Slide damping type water hydraulic overflow valve for high-pressure and high-flow systems

A sliding damping, large flow technology, applied in valve details, safety valves, balance valves, etc., can solve the problems of poor anti-pollution ability, inapplicability, and the valve core cannot be returned, and achieve improved reliability and anti-pollution ability. , Simple design and manufacture, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

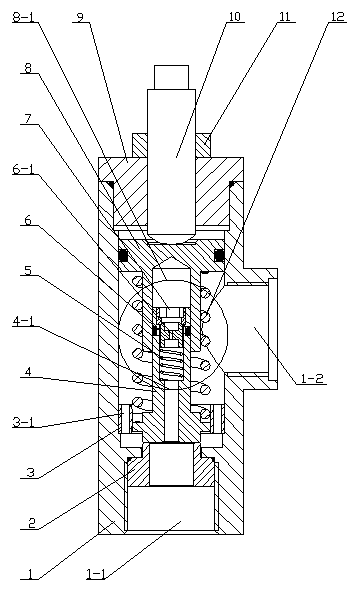

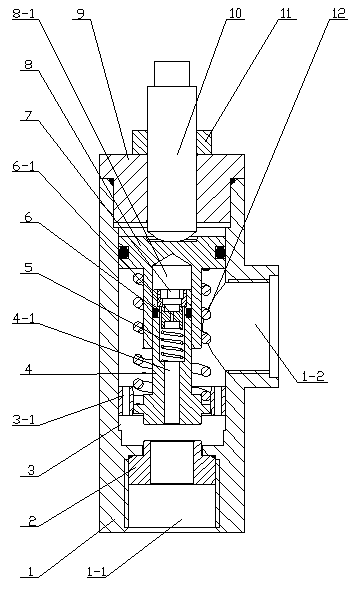

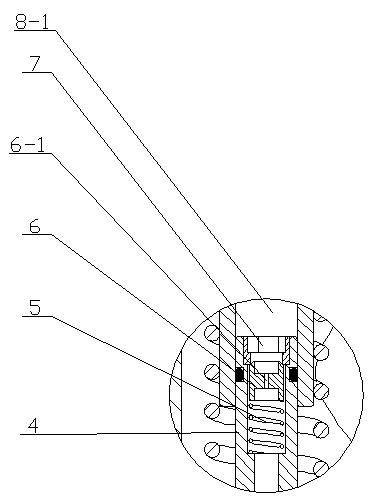

[0026] Such as figure 1 , 2 , 3, the present invention includes a valve body 1, a valve seat 2, a damping ring 3, a main valve core 4, a damping spring 5, a damper 6, a damping valve plate 7, a spring push rod 8, an upper end cover 9, and an adjusting screw 10 And the main spring 12, the valve body 1 is provided with a water inlet 1-1, a water outlet 1-2 and an end cap installation hole, the inner bottom of the valve body 1 is provided with a circular step, and the valve seat 2 is provided with an A water flow channel 2- 1. The valve seat 2 is installed on the inner bottom of the valve body 1. The damping ring 3 is a ring structure, and there are many small holes on the damping ring 3. The lower surface of the damping ring 3 is against the circular step at the inner bottom of the valve body 1. Above, the main valve core 4 is provided with an annular groove and a water flow channel 4-1, the main valve core 4 is installed in the damping ring 3, and the bottom of the main valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com