High-strength wear-resistant mixing drum for constructional engineering

A construction engineering, high-strength technology, applied in the direction of mixer accessories, mixers with rotating stirring devices, chemical/physical processes, etc., can solve the problem that the wear resistance, corrosion resistance and oil resistance can not meet the needs, and can not remove sludge , low service life of equipment and other problems, to achieve good sewage treatment effect, anti-corrosion ability and anti-cavitation wear performance, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

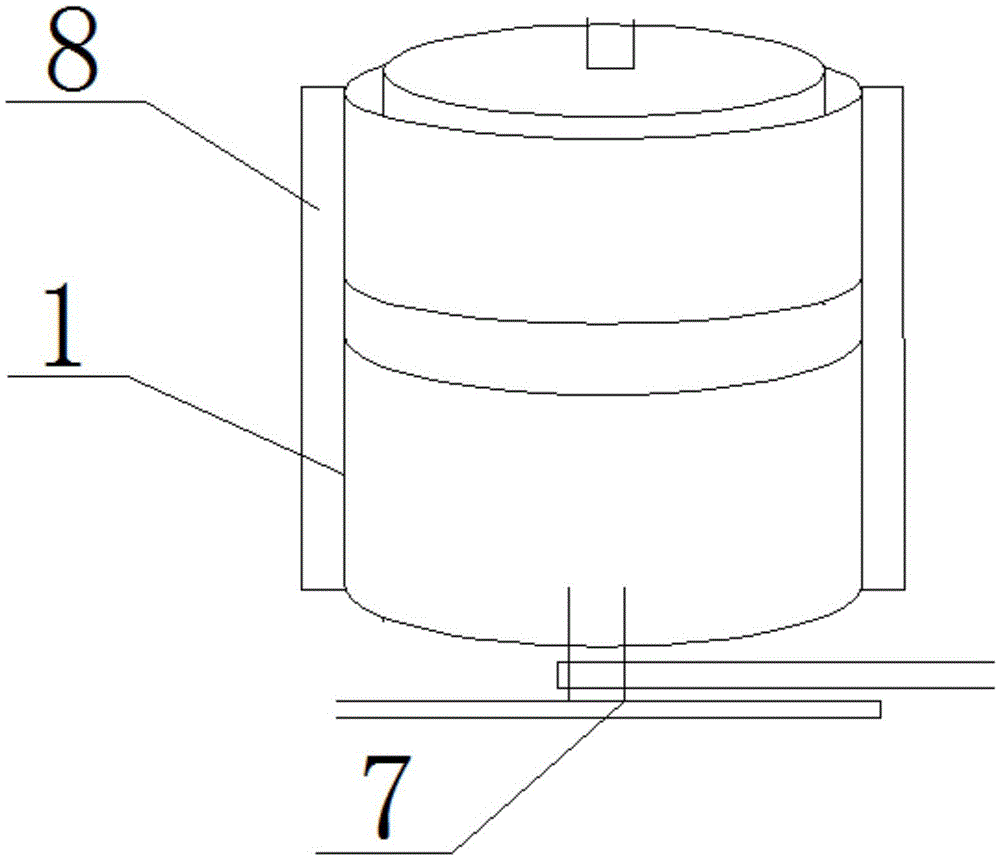

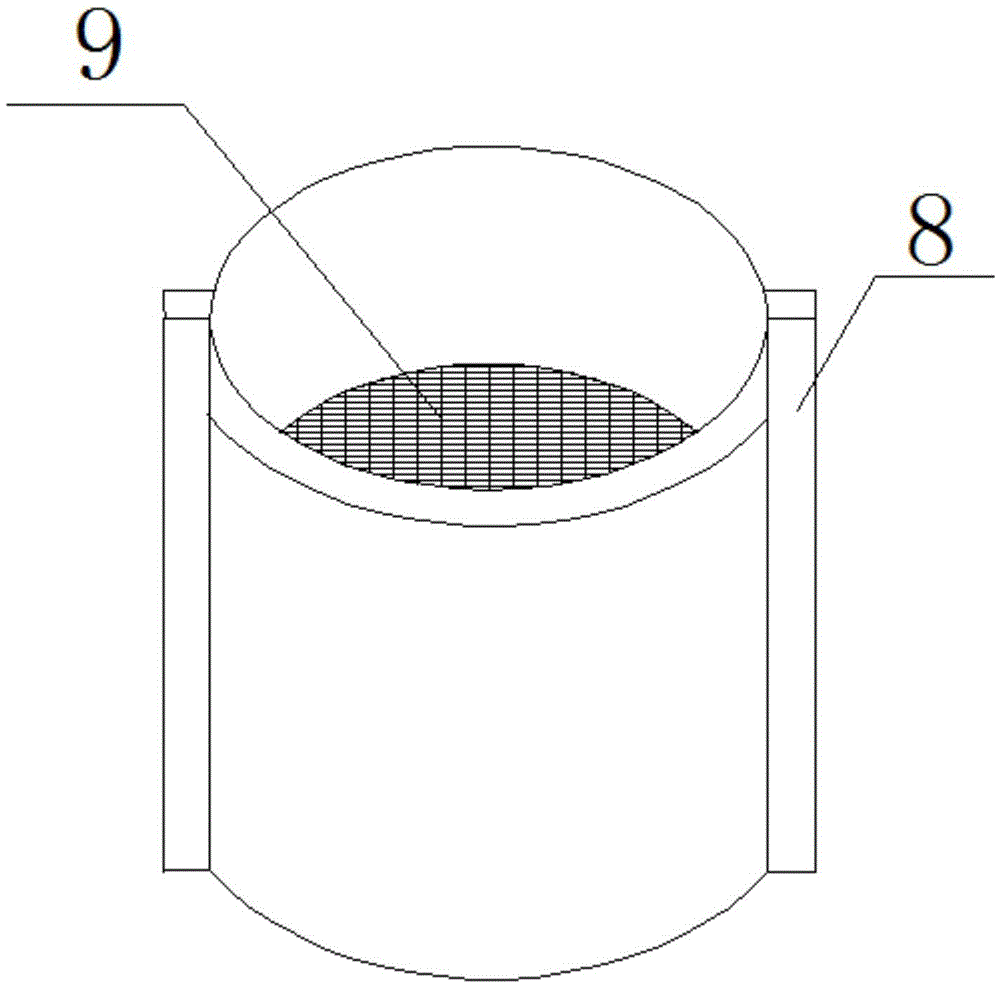

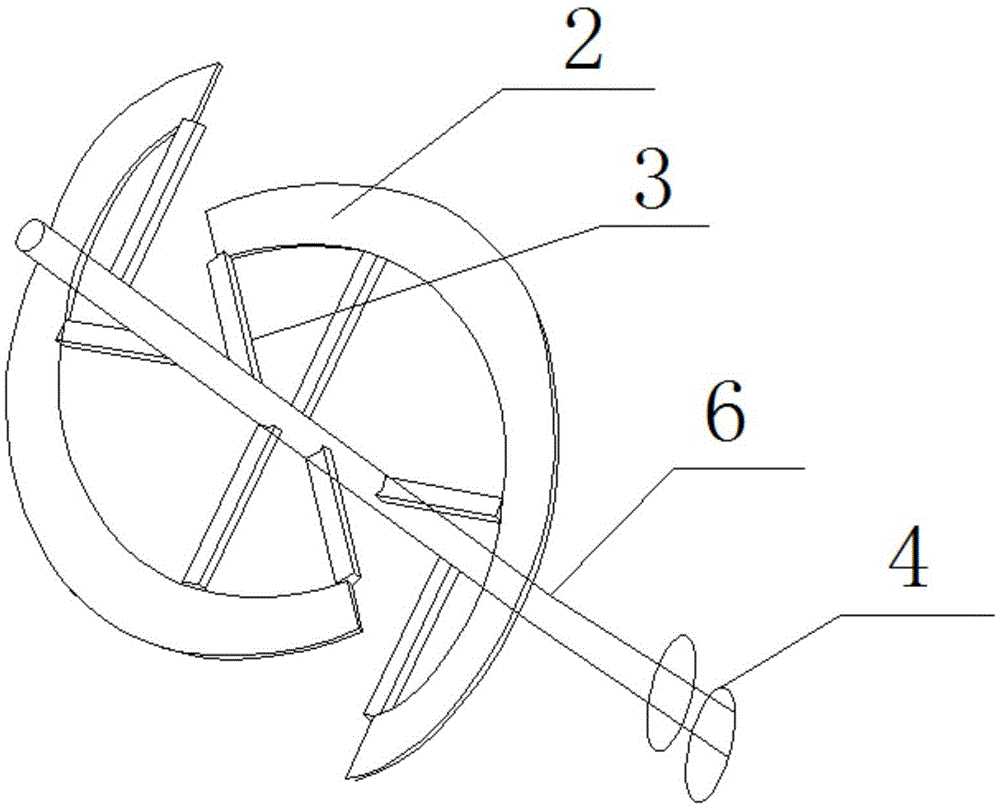

[0020] see Figure 1 to Figure 5 , the present invention provides a technical solution: a high-strength wear-resistant mixing cylinder for construction engineering, including a cylinder body 1, driving guide rails 8 are provided on both sides of the cylinder body 1, and a stirring device is arranged inside the cylinder body 1. Described stirring device comprises stirring blade 2, support column 3, rotating shaft 6 and rotating wheel 4, and described stirring blade 2 is installed on the rotating shaft 6 by supporting column 3, and described rotating wheel 4 is installed on the rotating disk 7, so There is also a liftable anti-settling net 9 between the drive rails 8; it also includes a power supply 10, a control unit 11, a drive circuit 14, a lifti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com