Preparation method of 3, 5-dibromo iodobenzene

A technology of dibromoiodobenzene and iodoaniline, applied in 3 fields, can solve problems such as many by-products, high toxicity, long reaction steps, etc., and achieves the effects of improving yield, easy operation and control, and being beneficial to industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 3 of the present invention, the preparation method of 5-dibromoiodobenzene comprises the following steps:

[0021] Step 1, the preparation step of 2,6-dibromo-4-iodoaniline intermediate, add p-iodoaniline and absolute ethanol in a container, under normal temperature conditions, add dibromohydantoin in batches; no raw materials are detected by HPLC When the product is produced, stop the reaction; directly filter to obtain the 2,6-dibromo-4-iodoaniline intermediate; the molar ratio of p-iodoaniline to dibromohydantoin is 1:1.

[0022] Step 2, add 2-, 6-dibromo-4-iodoaniline intermediate and hypophosphorous acid in another container, add sodium nitrite solution dropwise after cooling down, a large amount of solids will wash out after dropping, filter directly , recrystallized from absolute ethanol to obtain needle-like 3,5-dibromoiodobenzene. The molar ratio of 2,6-dibromo-4-iodoaniline intermediate to sodium nitrite is 1:1.

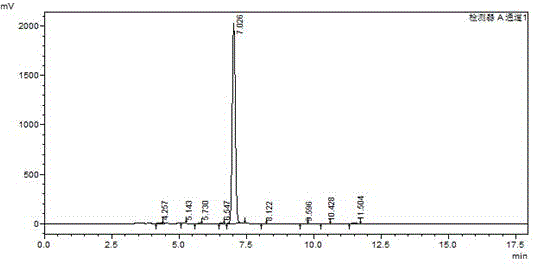

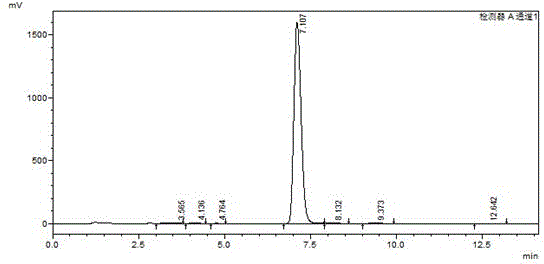

[0023] Preparation of intermediate 2,6-dibro...

Embodiment 2

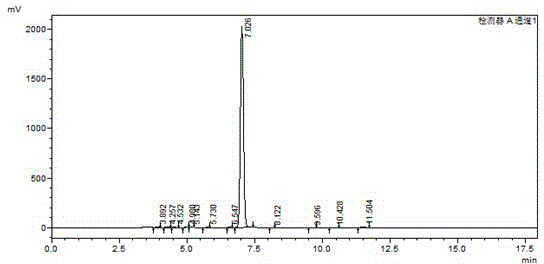

[0030] The preparation of intermediate 2,6-dibromo-4-iodoaniline: the detailed steps are as follows: wherein, the dosage is as follows: p-iodoaniline: 219g, dibromohydantoin: 290g, absolute ethanol: 1800ml. Add 219g of p-iodoaniline (1mol) and 1000ml of absolute ethanol into a 2000ml reaction bottle, stir for 20 minutes to disperse evenly. Then add 290 g of dibromohydantoin in batches, control the reaction temperature at 20-25° C., and complete the addition in about 2 hours. After the addition, a large amount of white solids will precipitate out. Reaction was continued at this temperature for 1 hour. The reaction was monitored by HPLC. When the raw materials disappeared, the reaction was stopped, filtered at 20-25°C, and dried under normal pressure at 100°C to obtain 350 g of off-white powdery solid. like image 3 And the HPLC collection of illustrative plates of 2,6-dibromo-4-iodoaniline shown in Table 3, collection of illustrative plates shows 2,6-dibromo-4-iodoaniline con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com