Polyethylene composition and film thereof

A polyethylene and composition technology, applied in the field of polyethylene composition and its film, can solve the problems of poor film-forming properties and easy cracking of the film, and achieve the effects of low haze, good strength and puncture resistance, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

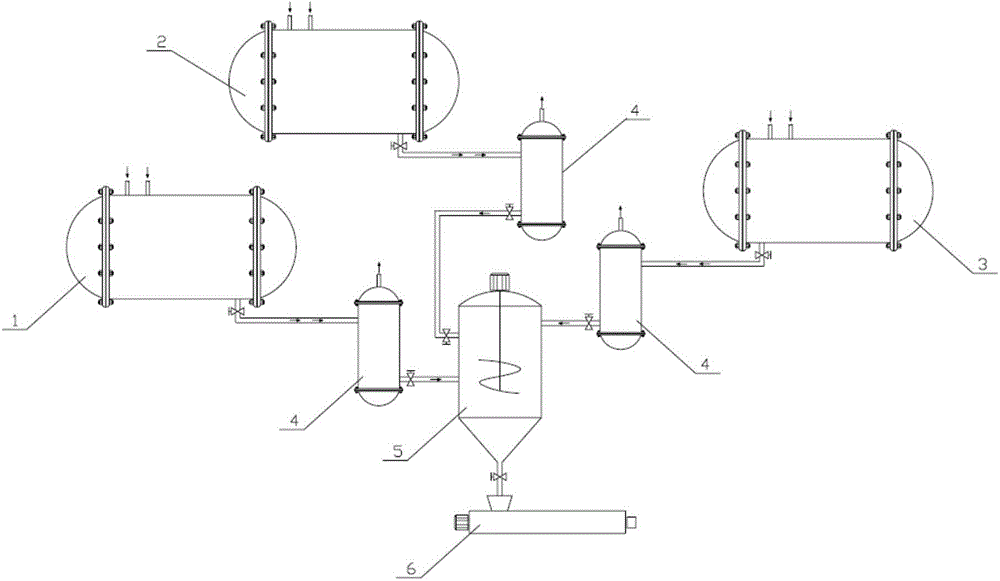

Image

Examples

Embodiment approach

[0021] According to a preferred embodiment of the present invention, the polyethylene composition contains component A, component C and optional component B; the component A is linear low density polyethylene copolymerized with ethylene / alpha olefin , its melt index MI at a temperature of 190°C and a load of 2.16kg A 0.01-2g / 10min, density ρ A 0.880-0.936g / cm 3 ; The component B is a linear low-density polyethylene copolymerized with ethylene / α-olefin, and its melt index MI at a temperature of 190°C and a load of 2.16kg B 2.1-9.9g / 10min, density ρ B 0.910-0.930g / cm 3 ; The component C is a linear low-density polyethylene copolymerized with ethylene / α-olefin, and its melt index MI at a temperature of 190°C and a load of 2.16kg C 10-80g / 10min, density ρ C 0.880-0.930g / cm 3 .

[0022] According to the polyethylene composition provided by the present invention, preferably, the melt index MI of the component A at a temperature of 190°C and a load of 2.16kg A 0.01-1.5g / 10min...

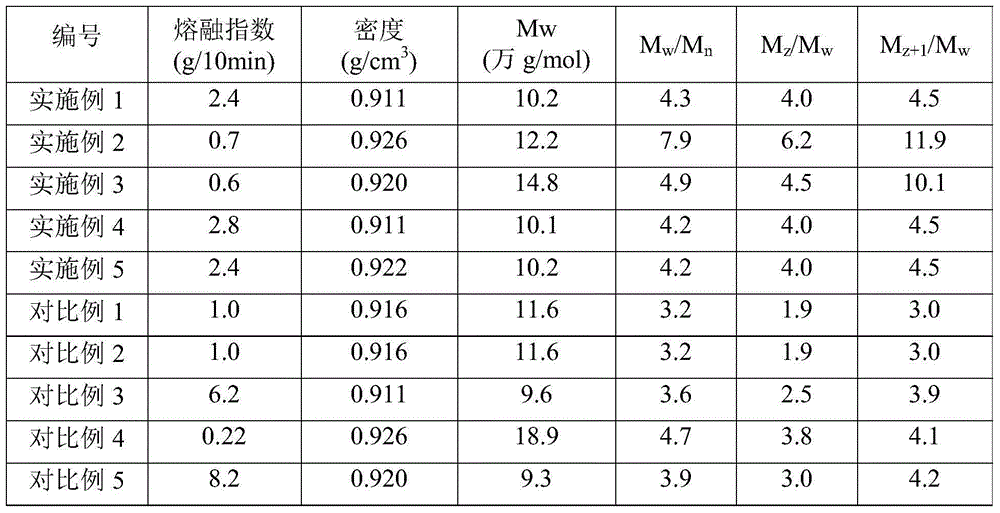

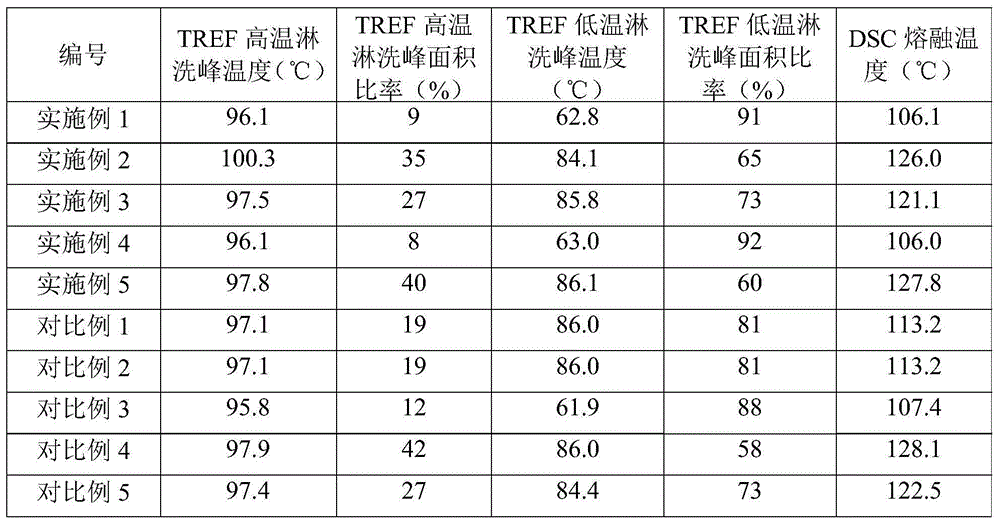

Embodiment 1

[0053] This example is used to illustrate the polyethylene composition and film thereof provided by the present invention.

[0054] (1) Preparation of polyethylene composition:

[0055] The polyethylene composition that this embodiment provides is made up of component A, component B and component C, and these three kinds of components are the linear low density polyethylene (LLDPE) of ethylene / alpha olefin copolymerization, wherein, component A and component B are prepared using a metallocene catalyst (the metallocene catalyst system is a supported metallocene catalyst prepared by CN102453124A embodiment 1, the same below), and component C is prepared using a Ziegler-Natta catalyst (the described The Ziegler-Natta catalyst system is prepared from the Ziegler-Natta catalyst system prepared in Example 1 of CN101838351A, the same below). Specific steps are as follows:

[0056] Add ethylene, α-olefin, hydrogen and nitrogen (ethylene, α-olefin, hydrogen and nitrogen are of polyme...

Embodiment 2

[0066] This example is used to illustrate the polyethylene composition and film thereof provided by the present invention.

[0067] (1) Preparation of polyethylene composition:

[0068] The polyethylene composition that this embodiment provides is made up of component A, component B and component C, and these three kinds of components are the linear low density polyethylene (LLDPE) of ethylene / alpha olefin copolymerization, wherein, component A and component B are prepared by using a metallocene catalyst, and component C is prepared by using a Ziegler-Natta catalyst. Specific steps are as follows:

[0069] Add ethylene, alpha olefin, hydrogen and nitrogen into the fluidized bed gas phase reactor, then add the catalyst system, and then polymerize under the conditions of temperature 84-88°C and pressure 1.8-2.0MPa to obtain components A, Component B and Component C. Among them, the control of the melt index of component A, component B and component C is realized by adjusting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com