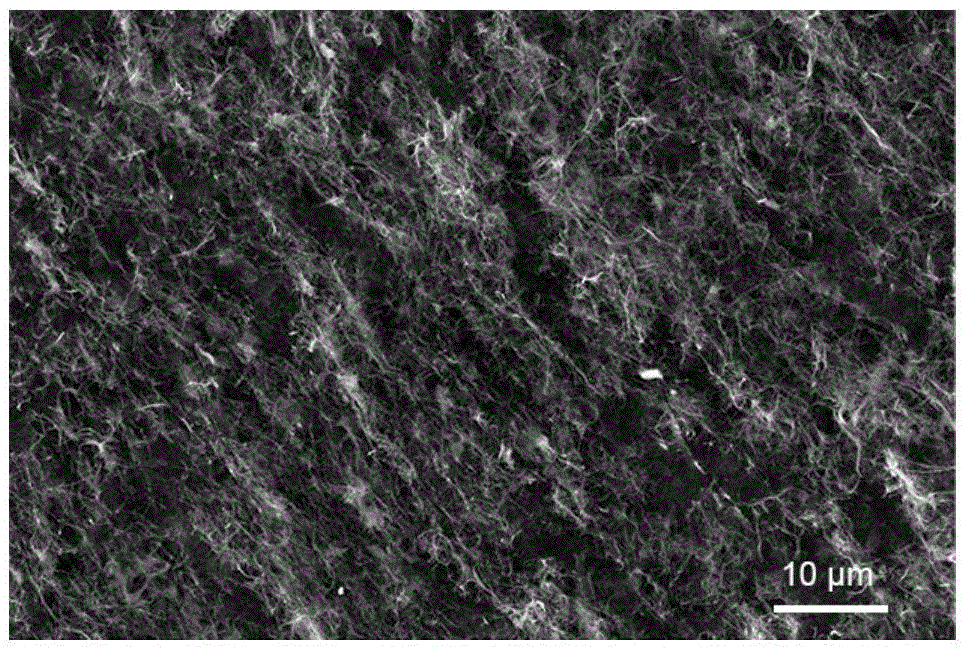

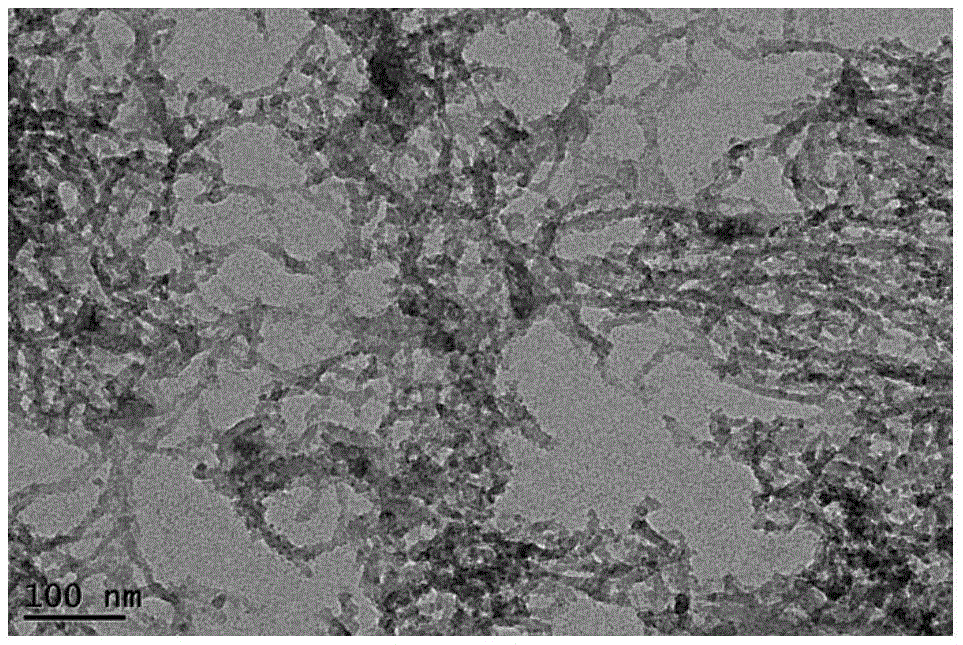

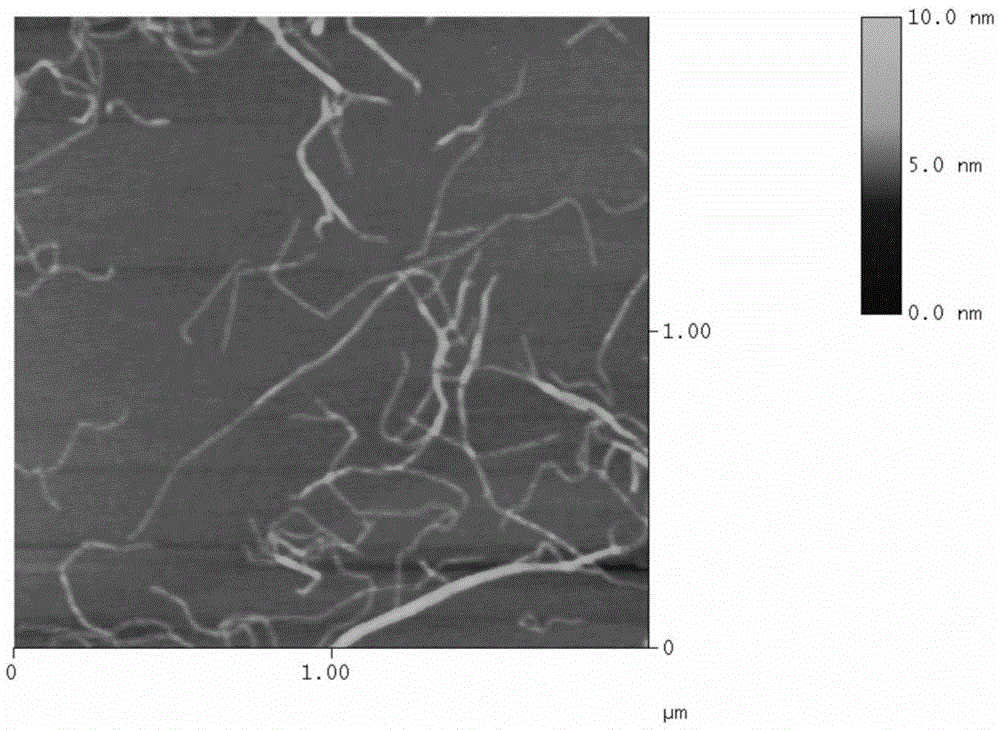

Chitin nano-fibril and preparation method thereof

A technology of nanofibrils and chitin, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of high corrosion of acid-base reagents, thick chitin nanofibrils, and different lengths of chitin. The effect of cost, richness and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0043] 1. Use benzene: ethanol to extract some organic matter from industrial waste shrimp shells at a ratio of 2:1, then use glacial acetic acid to adjust the pH to 4.5 and add 1wt% NaClO 2 Bleaching at 80°C for 3 hours;

[0044] 2. The bleached shrimp shells were prepared as a 1wt% solution to obtain a 1wt% coarse chitin solution by mechanical disc grinding;

[0045] 3. Put the above solution on a magnetic stirrer and stir for 15 minutes, so that chitin is evenly dispersed in the solution;

[0046] 4. Then add TEMPO, NaBr and NaClO, the molar ratio of TEMPO:NaBr:NaClO is 0.1:1:2.5, quickly seal the container and heat it to 80°C for 2 hours, after the reaction, add ethanol 20 times NaClO (molar ratio) to stop Reaction, the solution obtained is washed to neutrality with deionized water;

[0047] 5. Add the above treated solution to NaClO 2 , heated to 40-90°C, reacted for 2 hours, then washed with deionized water until neutral

[0048] 6. Prepare the solution obtained abov...

specific Embodiment 2

[0050] 1. Clean the industrial waste shrimp skin, crush it through an 80-mesh sieve, prepare a 1wt% solution, and store it at 4°C

[0051] 2. Disc-milling the above-mentioned solution by means of mechanical disc-grinding to obtain a coarse chitin dispersion solution;

[0052] 3. Take 400ml of the above solution, stir it evenly, add TEMPO and NaBr, and then add NaClO, the molar ratio of TEMPO:NaBr:NaClO is 0.1:1:2.5, and 0.5mol / L NaOH should be used to control the concentration of the solution during the dropping process. pH=10±0.5, after the dropwise addition, seal the container and heat to 75°C under magnetic stirring, react for 80 minutes, add ethanol 10 times NaClO (molar ratio) after the reaction to terminate the reaction;

[0053] 4. Rinse the obtained solution repeatedly with deionized water to neutrality, then add 8gNaClO 2 (80%) heated to 80°C, further bleached, then washed to neutral, and stored at 4°C;

[0054] 5. Prepare the solution obtained above into a 1.5% dis...

specific Embodiment 3

[0056] 1. Extract the crab shells with benzene:ethanol at a ratio of 2:1 at 80°C for 10 hours, then use hydrochloric acid to adjust the pH to 4-5 and add 1wt% NaClO 2 Heat at 80°C for 2h;

[0057] 2. Take 400ml of the above solution, stir evenly, add 0.064g of TEMPO and 0.4g of NaBr, disperse evenly, then add 2ml of 2mol / L NaClO, use 0.5mol / L of NaOH to control the pH of the solution at 10±0.5, under magnetic stirring Heat to 75°C for 2 hours, then add 20ml of ethanol to terminate the reaction, and wash the obtained solution with deionized water until neutral;

[0058] 3. Add the solution obtained above to 8gNaClO 2 (80wt%), heated to 85°C, reacted for 2.5h, then washed to neutral with deionized water;

[0059] 4. The solution obtained above was formulated into a 1% dispersion, and then the solution was treated with high-speed shear (1800W) for 40 minutes;

[0060] 5. Treat the obtained above solution with a centrifuge at 5000rpm for 10min, take the supernatant, and 2 Ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com