Carbon crystal heating equipment

A heating equipment, carbon crystal technology, applied in the field of carbon crystal heating equipment, can solve the problems of smoke poisoning, high cost, inconvenient operation and use, etc., and achieve the effects of fast heating and heat dissipation, good health care effect, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

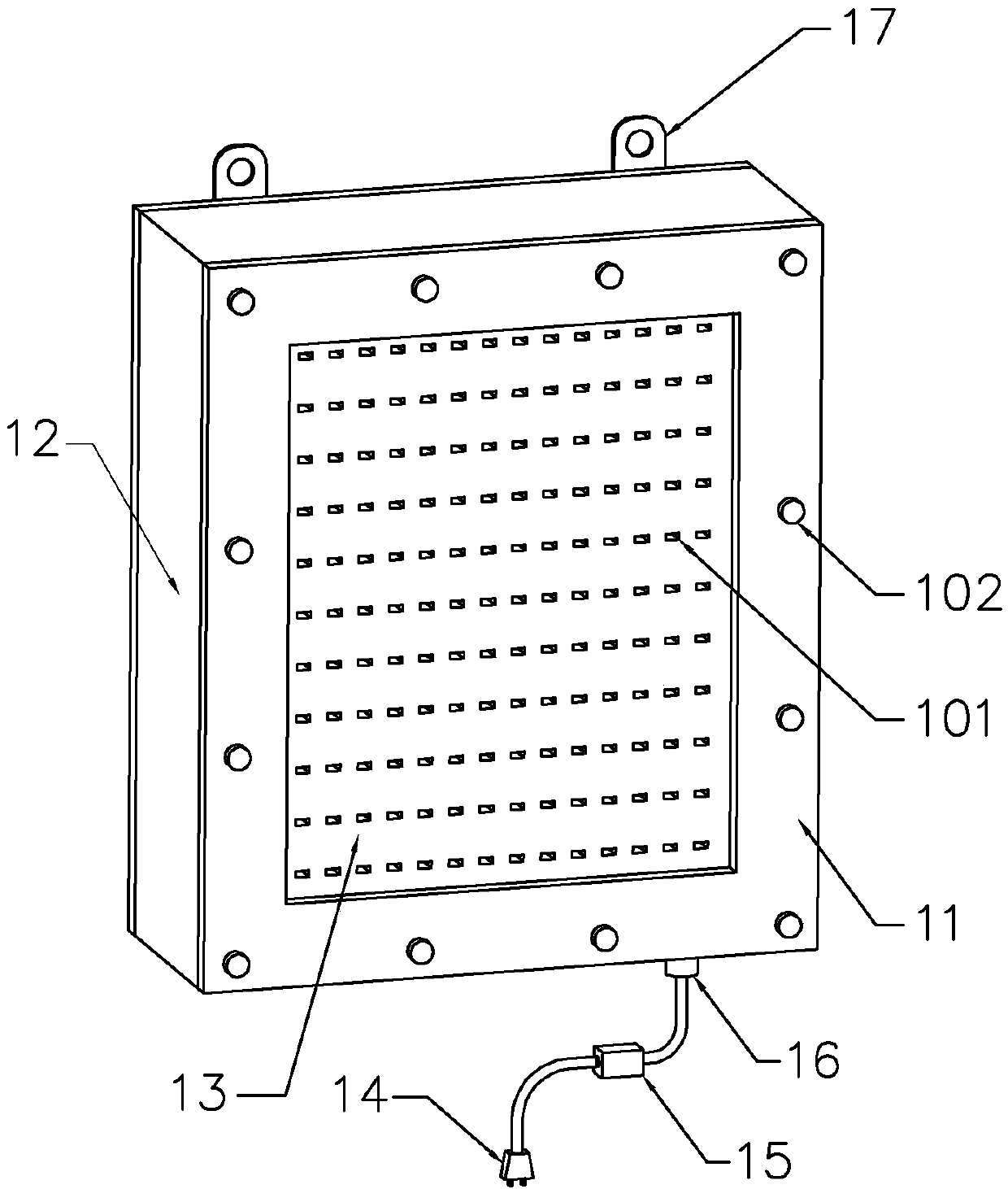

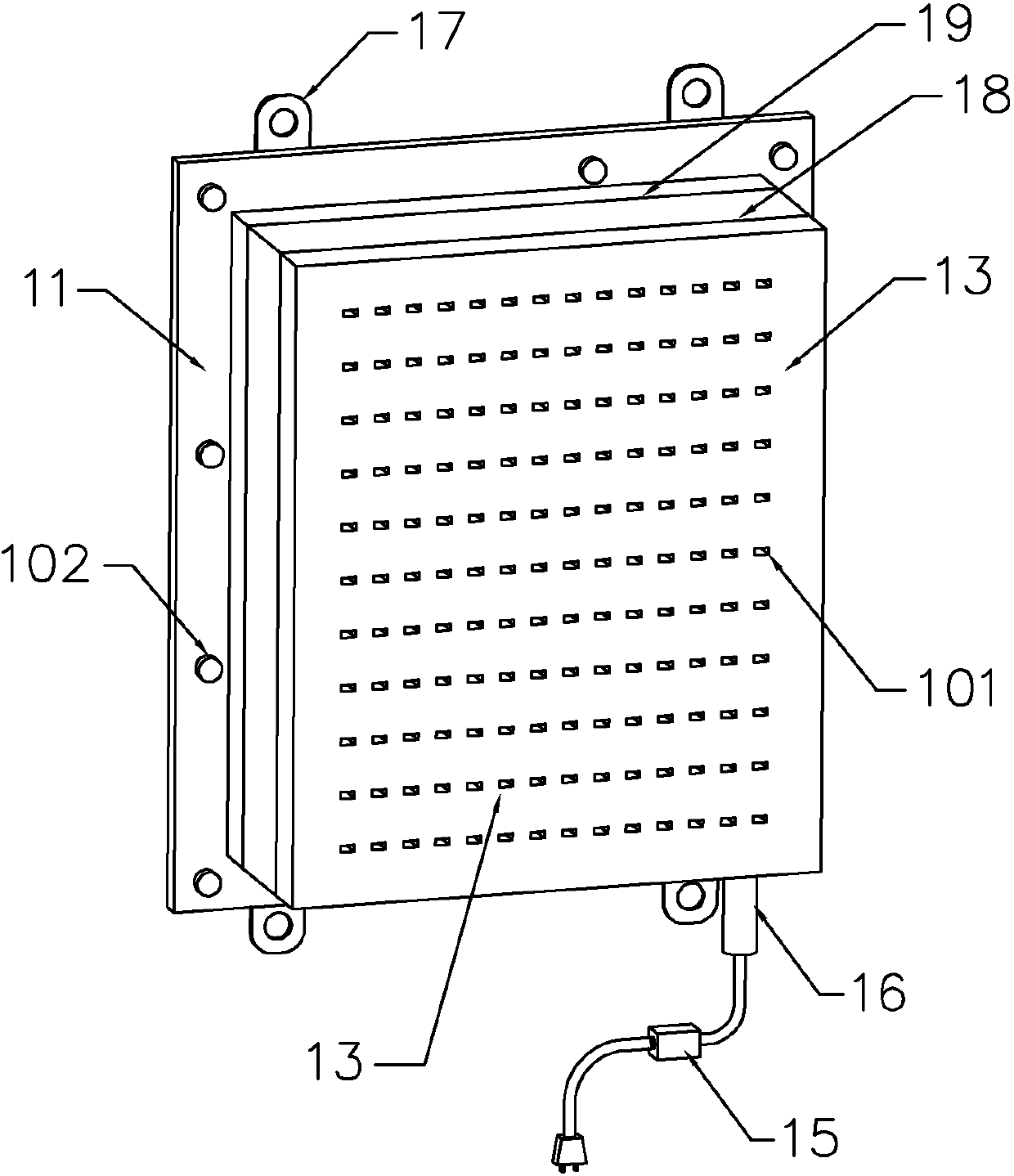

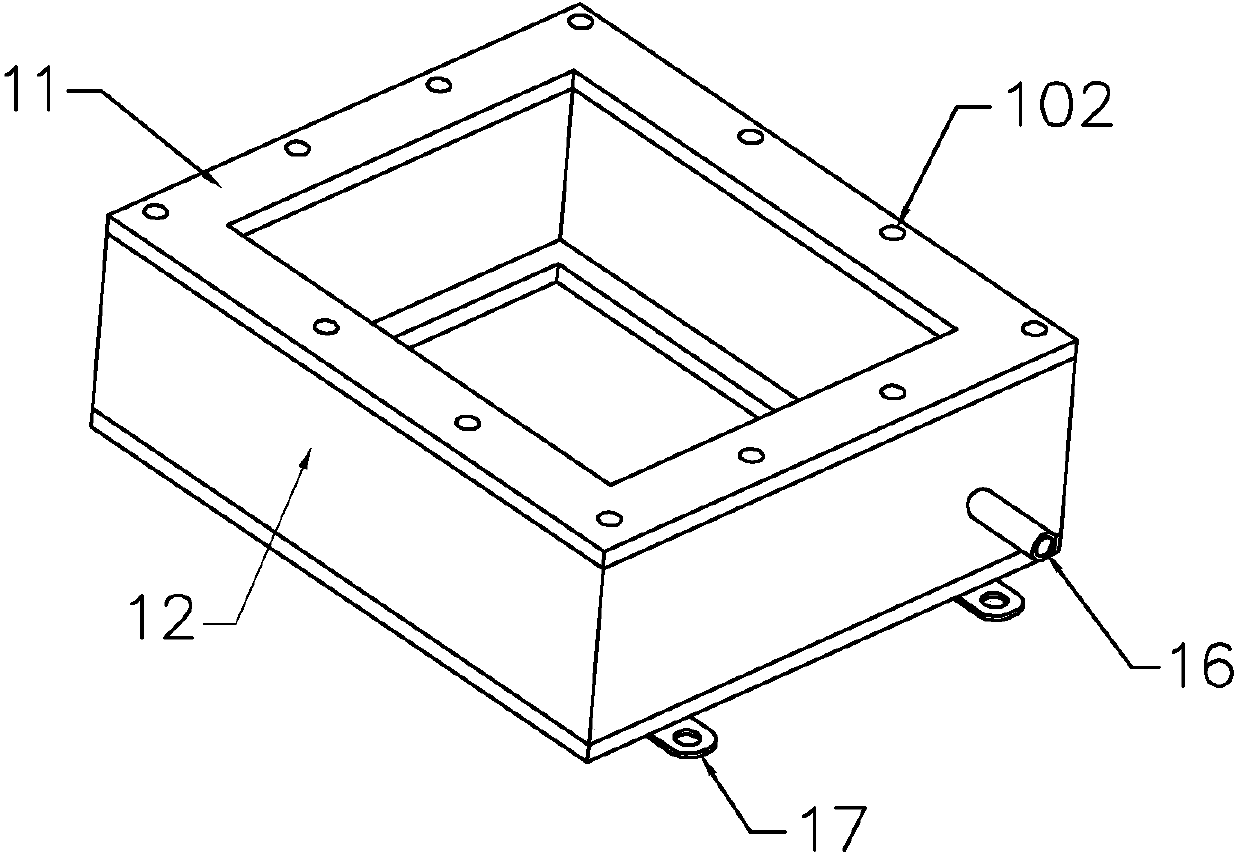

[0019] Embodiment 1, a carbon crystal heating device, mainly includes a heat preservation frame body 12, a carbon crystal heating plate 18, a heat insulation board 19 and a fireproof board 13, the heat preservation frame body 12 is rectangular, and the upper and lower parts of the heat preservation frame body 12 are provided with Frame 11, the two are connected by screws 102; the upper frame 11 is provided with a fireproof board 13, a carbon crystal heating board 18, and a heat insulation board 19 sequentially from the outside to the inside, and the fireproof board 13 is located in the heat preservation frame 12, and the fireproof board 13 is provided with There are heat dissipation holes 101, and the lower part of the fireproof board 13 is provided with a carbon crystal heating plate 18, which is located in the heat preservation frame 12, and the carbon crystal heating plate 18 dissipates heat to the outside through the heat dissipation holes 101 on the fireproof board 13; The...

Embodiment 2

[0021] Embodiment 2, during use, the carbon crystal heating equipment can be connected to the inverter 15 through the power cord, the end of the power cord is connected with a power plug 14, and the power plug 14 is connected to the storage battery to dissipate heat for heating; the inverter 15 Connected to the battery, after the voltage is transformed, it can charge mobile phones, laptops, etc., and can also be used as a power source to charge other electric vehicles.

[0022] The user can make corresponding adjustments according to the size of the operating space, the thickness of the carbon crystal heating plate or its length and width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com