Two-step chromium slag detoxification formula and synergistic process

A chromium slag and process technology, applied in the field of two-step chromium slag detoxification formula and synergistic process, can solve problems such as secondary pollution, and achieve the effects of avoiding poisoning danger, reducing heavy metal content, and simple and efficient energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

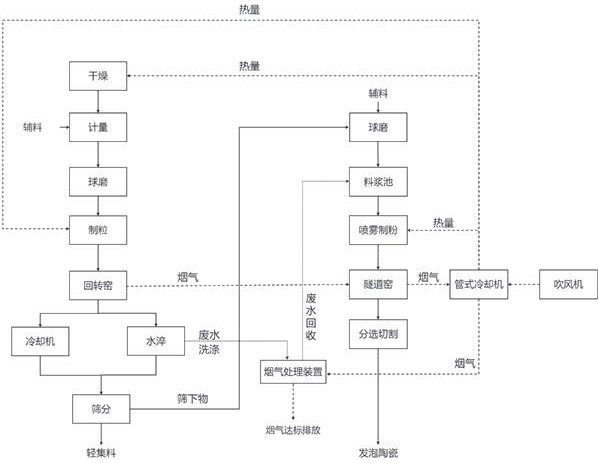

[0044] Such as figure 1 As shown, the chromium slag detoxification process in the present embodiment comprises the following steps:

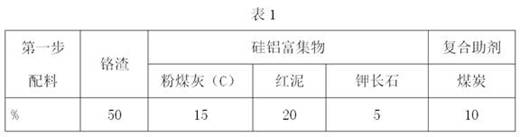

[0045] S1: Ingredients, mix 50% of chromium slag, 30% of red mud, 10% of potassium feldspar, and 10% of ferrous sulfate for granulation. The diameter of the material is 5-20mm, and it is dried to ensure that the obtained spherical material contains water. The drying rate does not exceed 10%, and the granulation rate reaches 99%. The heat used for drying can come from the heat of the firing section of the foamed ceramics, and enters the rotary kiln together with the materials.

[0046] S2: Put the pellets into the rotary kiln for high-temperature firing. The moisture content of the incoming material does not exceed 16%. The maximum temperature in the firing section of the kiln is 900°C, and the residence time is 2h. The flue gas in this step is recycled to the tunnel kiln. .

[0047] S3: Quenching the calcined light aggregate with water at 25°C...

Embodiment 2

[0074] Such as figure 1 As shown, the chromium slag detoxification process in the present embodiment comprises the following steps:

[0075] S1: Ingredients, mixing 40% of chromium slag, 35% of red mud, 15% of potassium feldspar, and 10% of sodium borohydride for granulation. The diameter of the material is 5-20mm, and it is dried to ensure that the obtained spherical material contains water. The drying rate does not exceed 10%, and the granulation rate reaches 99%. The heat used for drying can come from the heat of the firing section of the foamed ceramics, and enters the rotary kiln together with the materials.

[0076] S2: Put the pellets into the rotary kiln for high-temperature firing. The moisture content of the incoming material does not exceed 16%. The maximum temperature in the firing section of the kiln is 900°C, and the residence time is 2h. The flue gas in this step is recycled to the tunnel kiln. .

[0077] S3: Quenching the calcined light aggregate with water a...

Embodiment 3

[0088] Such as figure 1 As shown, the chromium slag detoxification process in the present embodiment comprises the following steps:

[0089] S1: Ingredients, mixing 60% of chromium slag, 35% of red mud, 12% of potassium feldspar, and 3% of manganese slag for granulation, the diameter of the discharge is 5-20mm, and drying treatment to ensure the moisture content of the obtained spherical material No more than 10%, the granulation rate reaches 99%, the heat used for drying can come from the heat of the firing section of the foamed ceramics, and enters the rotary kiln together with the materials.

[0090] S2: Put the pellets into the rotary kiln for high-temperature firing. The moisture content of the incoming material does not exceed 16%. The maximum temperature in the firing section of the kiln is 900°C, and the residence time is 2h. The flue gas in this step is recycled to the tunnel kiln. .

[0091] S3: Quenching the calcined light aggregate with water at 25°C, and the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com