Gas expansion device, throat machining method of expansion pipe and application

A technology of a gas expansion device and a processing method, applied in the field of expansion devices, can solve the problems of flying head, high defective rate, heavy weight, etc., and achieve the effects of reducing production cost, easy acquisition and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

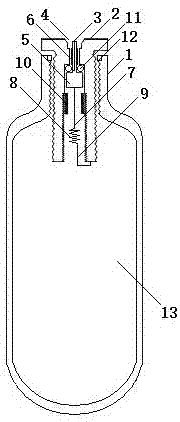

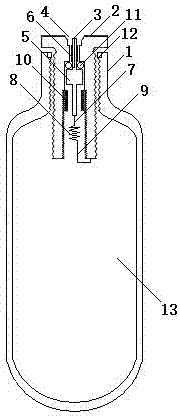

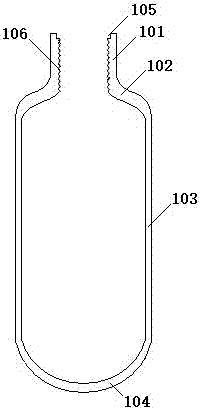

[0055] An expansion device includes an expansion tube 1 and an inflatable ignition head 2. One end of the expansion tube 1 is contracted and sealed, and the other end is contracted with an inflatable ignition head 2. A storage space is formed between the contracted and sealed end 104 and the inflatable ignition head 2. Energy chamber 13; The gas-filled ignition head 2 includes a gas-filled seat body 201, a through hole 202, a valve cavity 203, an ignition chamber 204, a gas nozzle 4, a conductive valve 5, an insulating layer 6, an electric heating wire 8, a retaining ring 10, and a first Sealing ring 11, the middle of the upper end of the inflatable seat body 201 is provided with an inflator 4, a through hole 202 is provided under the inflator nozzle 4, a valve cavity 203 is provided under the through hole 202, and an ignition cavity 204 is provided under the valve cavity 203. A conductive valve 5 and a first sealing ring 11 are provided in 203, and a retaining ring 10 is provid...

Embodiment 2

[0059] As the expansion device described in Example 1, in order to facilitate the connection of the heating wire 8, the conductive valve 5 has an inflatable conductive thimble 501 at one end, and a conductive needle 503 at the other end. When the conductive valve core 502 is in the middle, the conductive needle 503 is connected to the heating wire 8. One end, the other end of the heating wire 8 is connected to the inflatable seat body 201; the expansion tube is made of non-ferrous metal material or metal alloy or ABS or steel or copper alloy or aluminum alloy; the material strength of the conductive valve 5 is the same as the energy storage cavity 13 inside the bottle. The energy pressure is proportional; the material strength of the conductive valve 5 is slightly greater than the energy storage pressure in the energy storage chamber 13 bottle.

Embodiment 3

[0061] As in the expansion device described in embodiment 1 or 2, the bottle mouth 101 is provided with a sealing groove 105, and the sealing groove 105 is provided with a second sealing ring 12; the inner wall of the ignition cavity 204 is provided with an internal thread 205 and a retaining ring 10 The outer wall is provided with an external thread 206 matching the internal thread 205; the thickness of the neck 102 is 20mm, the thickness of the necked end 104 is 20mm, and the thickness of the bottle body 103 is 2mm; the neck 102 and the neck of the expansion tube 1 The necked sealing end 104 is thickened through necking processing; the second sealing ring 12 adopts an O-ring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com