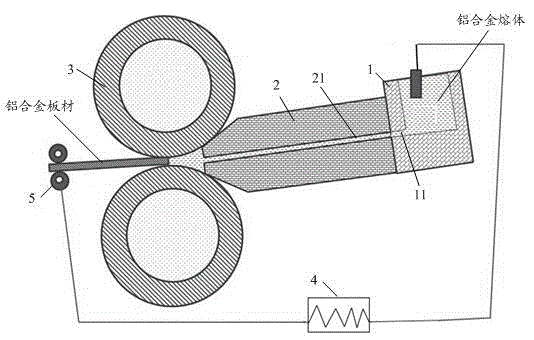

Cast-rolling mechanism for aluminum alloy plates

A technology of aluminum alloy sheet and aluminum alloy melt, which is applied in the field of aluminum alloy sheet production, can solve the problems of delamination, unmelted eutectic phase of casting billet, difficulty in producing 7075 sheet, etc., so as to reduce diffusion capacity and reduce alloying elements. content, reducing the effect of macrosegregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] 1) The diameter of the casting roll is 860mm, the pouring temperature is 680°C, the thickness of the casting plate is 8mm, and the casting speed is 0.65m / min.

[0029] 2) The diameter of the casting roll is 920mm, the pouring temperature is 675°C, the thickness of the casting plate is 7mm, and the casting speed is 0.9m / min.

[0030] 3) The diameter of the casting roll is 1020mm, the pouring temperature is 665°C, the thickness of the casting plate is 6.5mm, and the casting speed is 1.5m / min.

[0031] The invention adopts low-temperature casting in the casting and rolling mechanism of the aluminum alloy plate, which is beneficial to form more crystal nuclei at the front of solidification in the casting and rolling area, refine the grains, and reduce the diffusion ability of alloy elements at the same time, so that more alloy elements are formed during the solidification process. Alloys remain in the solid phase, reducing the content of alloying elements in the residual me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com