A kind of mold processing technology of led optical lens

A mold processing and optical lens technology, which is applied in the field of optical lens molds, can solve the problems of dull knives, rough surface, loss of turning and milling tools, etc., and achieves the effects of long service life, smooth surface and easy turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

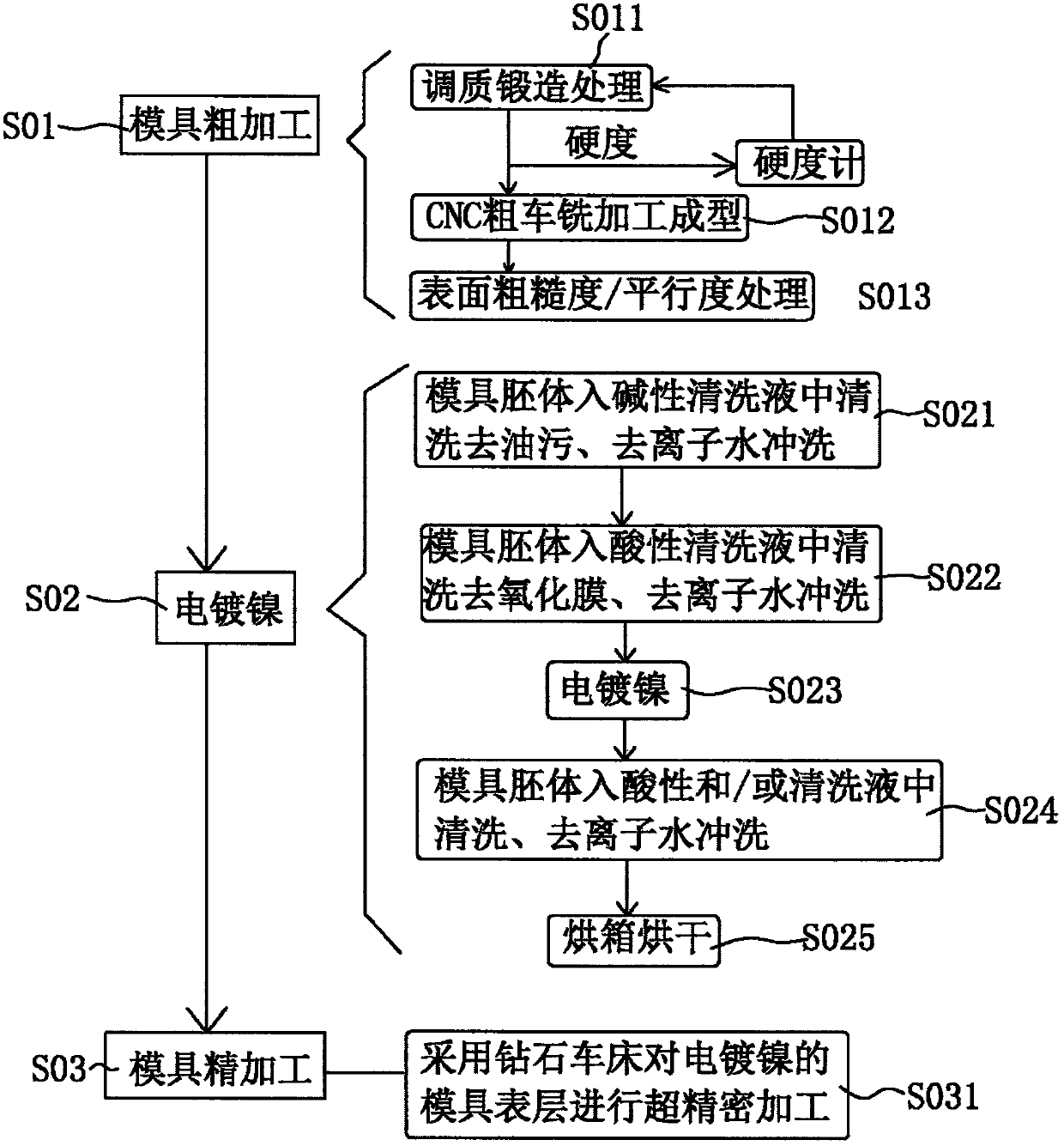

[0020] Embodiment one, refer to the attached figure 1 , a kind of mold processing technology of LED optical lens, is divided into following steps and finishes: mold rough machining (S01)-nickel plating (S02)-mould precision machining (S03), its concrete steps are as follows:

[0021] Step S01, mold rough machining, which includes:

[0022] Step S011, select the die steel material for conventional quenching and tempering forging treatment, wherein the hardness of the die steel material is 30HRC-36HRC. Then send it back for re-conditioning treatment; step S012, use CNC lathe to rough-mill the mold body and make the lens forming surface; step S013, perform surface roughness Ra and parallelism treatment on the lens forming surface completed by turning and milling, and the processed lens The surface roughness Ra of the molding surface is 0.5um, and the parallelism is 1um.

[0023] Step S02, electroplating nickel on the surface of the molding surface of the mold, and electroplatin...

Embodiment 2

[0028] Embodiment 2, a mold processing technology of LED optical lens is completed in the following steps: mold rough machining (S01)-nickel electroplating (S02)-mold precision machining (S03), and its specific steps are as follows:

[0029] Step S01, mold rough machining, which includes:

[0030] Step S011, select the die steel material for conventional quenching and tempering forging treatment, wherein the hardness of the die steel material is 30HRC-36HRC. Then send it back for re-conditioning treatment; step S012, use CNC lathe to rough-mill the mold body and make the lens forming surface; step S013, perform surface roughness Ra and parallelism treatment on the lens forming surface completed by turning and milling, and the processed lens The surface roughness Ra of the molding surface is 0.1um, and the parallelism is 2um.

[0031] Step S02, electroplating nickel on the surface of the molding surface of the mold, and electroplating nickel includes the following processes: ...

Embodiment 3

[0036] Embodiment 3, a kind of mold processing technology of LED optical lens is divided into the following steps to complete: mold rough machining (S01)-nickel plating (S02)-mold precision machining (S03), and its specific steps are as follows:

[0037] Step S01, mold rough machining, which includes:

[0038]Step S011, select the die steel material for conventional quenching and tempering forging treatment, wherein the hardness of the die steel material is 30HRC-36HRC. Then send it back for re-conditioning treatment; step S012, use CNC lathe to rough-mill the mold body and make the lens forming surface; step S013, perform surface roughness Ra and parallelism treatment on the lens forming surface completed by turning and milling, and the processed lens The surface roughness Ra of the molding surface is 0.4um, and the parallelism is 1.5um.

[0039] Step S02, electroplating nickel on the surface of the molding surface of the mold, and electroplating nickel includes the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com