Pretreatment device for raw water of artificial wetland and pretreatment process for raw water of artificial wetland

A pretreatment device and artificial wetland technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as blockage, achieve no flow loss, reduce land occupation, and save sewage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

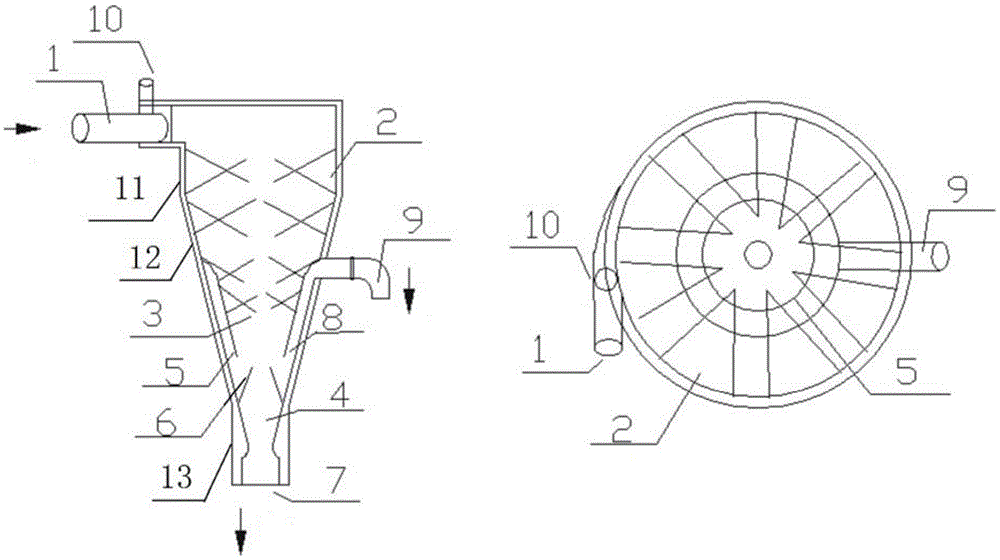

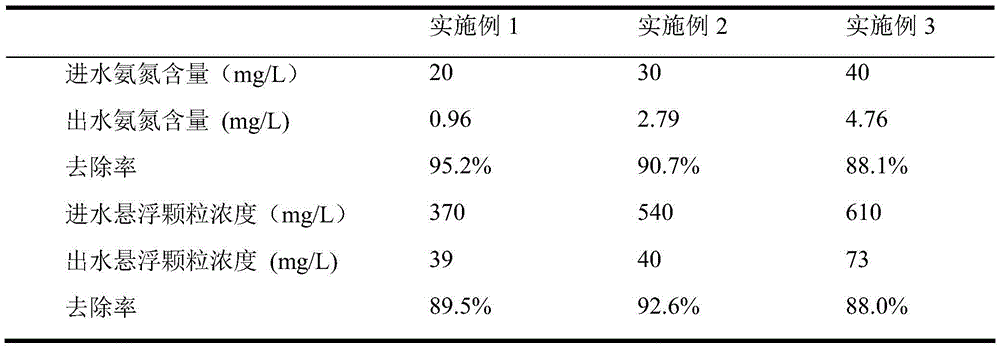

[0046] The artificial wetland pretreatment process using the above-mentioned device includes the following steps:

[0047] 1) Prepare the raw water with an ammonia nitrogen concentration of 20mg / L and a suspended particle concentration of 370mg / L, flow it tangentially into the above device at a flow rate of 12m / s, and flow through the spoiler to accelerate the flow rate of the raw water, changing from laminar flow to turbulent flow;

[0048] 2) The oxidizing agent is regularly added to the dosing port, and the amount of the oxidizing agent is controlled by the ammonia nitrogen content in the effluent reaching a specified value. In this embodiment, the oxidizing agent is sodium hypochlorite powder, and the dosage is 12 mg / L;

[0049] 3) When the raw water flows through the cylindrical separation chamber, the suspended particles with a higher density than the fluid can overcome the hydraulic resistance and move toward the central axis of the pretreatment device to form a central ...

Embodiment 2

[0052] The artificial wetland pretreatment process using the above-mentioned device includes the following steps:

[0053] 1) Prepare the raw water with an ammonia nitrogen concentration of 30mg / L and a suspended particle concentration of 540mg / L, flow it tangentially into the above device at a flow rate of 12m / s, and flow through the spoiler to accelerate the flow rate of the raw water, changing from laminar flow to turbulent flow;

[0054] 2) The oxidizing agent is regularly added to the injection port, and the amount of the oxidizing agent is controlled so that the ammonia nitrogen content in the effluent reaches a specified value. In this embodiment, the oxidizing agent is sodium hypochlorite powder, and the dosage is 16 mg / L;

[0055] 3) When the raw water flows through the cylindrical separation chamber, the suspended particles with a higher density than the fluid can overcome the hydraulic resistance and move toward the central axis of the pretreatment device to form a c...

Embodiment 3

[0058] The artificial wetland pretreatment process using the above-mentioned device includes the following steps:

[0059] 1) Prepare the raw water with an ammonia nitrogen concentration of 40mg / L and a suspended particle concentration of 610mg / L, flow it tangentially into the above device at a flow rate of 12m / s, and flow through the spoiler to accelerate the flow rate of the raw water, changing from laminar flow to turbulent flow;

[0060] 2) The oxidizing agent is regularly added to the injection port, and the amount of the oxidizing agent is controlled by the ammonia nitrogen content in the effluent reaching a specified value. In this embodiment, the oxidizing agent is sodium hypochlorite powder, and the dosage is 20 mg / L;

[0061] 3) When the raw water flows through the cylindrical separation chamber, the suspended particles with a higher density than the fluid can overcome the hydraulic resistance and move toward the central axis of the pretreatment device to form a centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com