Buffer damping anchor stock

A buffer damping and damping rod technology, applied in climate change adaptation, sheet pile walls, excavation, etc., can solve the problems of rockfall easily breaking through high-strength metal grids and ring metal meshes, and the accumulation of unsolved rockfalls, so as to avoid fractures. , the effect of strong damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

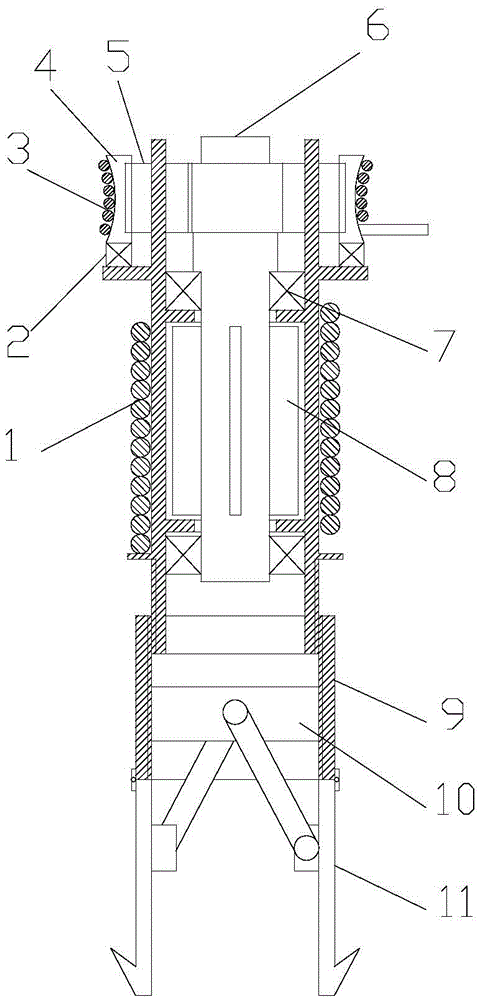

[0020] figure 1 It is a structural schematic diagram of the present invention; the buffer damping anchor of this embodiment includes at least two buffer anchors, a protective net connected between the two buffer anchors through a steel rope 3, and a control assembly for controlling the damping force of the buffer anchors; The buffer anchor includes a winch 4 for winding the steel rope 3, a lower rod body that can be inserted into and fixed to the slope soil, an upper rod body that is rotatably matched with the winch 4, and a magnet that applies rotational damping force to the winch 4. The rheological fluid assembly; the magnetorheological fluid assembly includes a magnetorheological fluid cavity arranged inside the upper rod body, a damping rod 6 passing through the magnetorheological fluid cavity in the axial direction and rotatably matched with the upper rod body; The rod section of the damping rod 6 located in the magnetorheological fluid chamber is fixed with blades 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com