Three-dimensional micro-nano trigger probe

A trigger probe and micro-nano technology, applied in the field of micro-nano testing, can solve the problems of low detection sensitivity and precision of strain gauges, difficult installation and adjustment, complex structure, etc., and achieve the effect of clear measurement, simple and applicable method, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

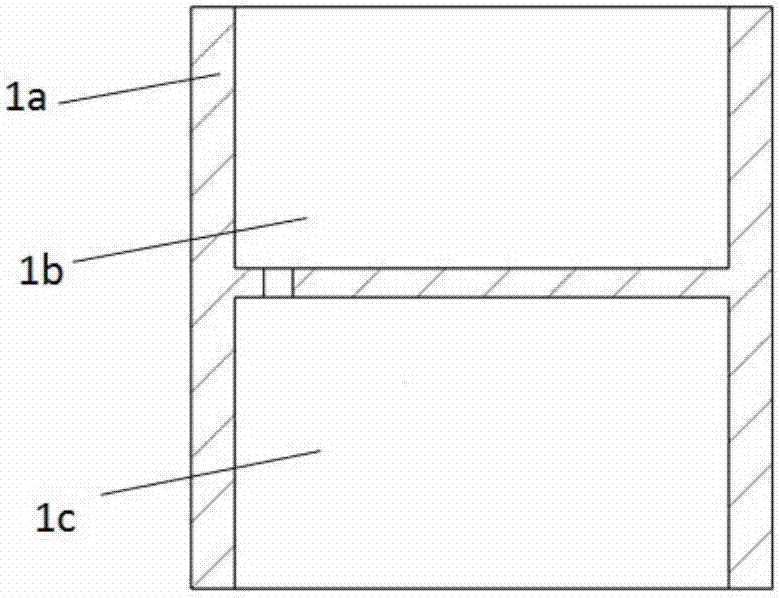

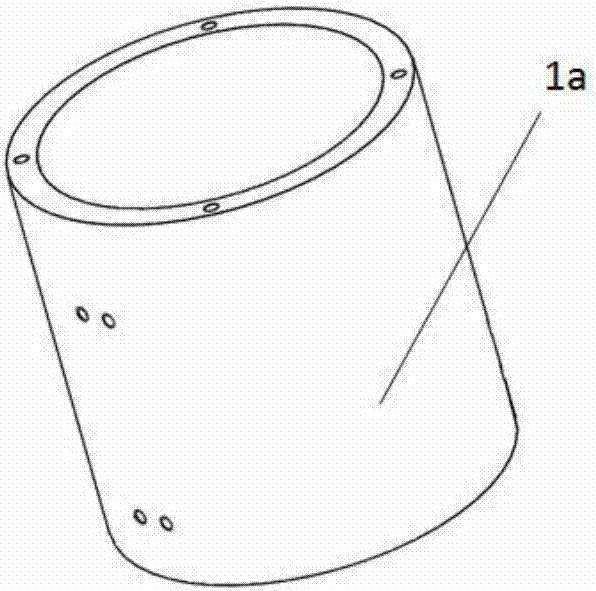

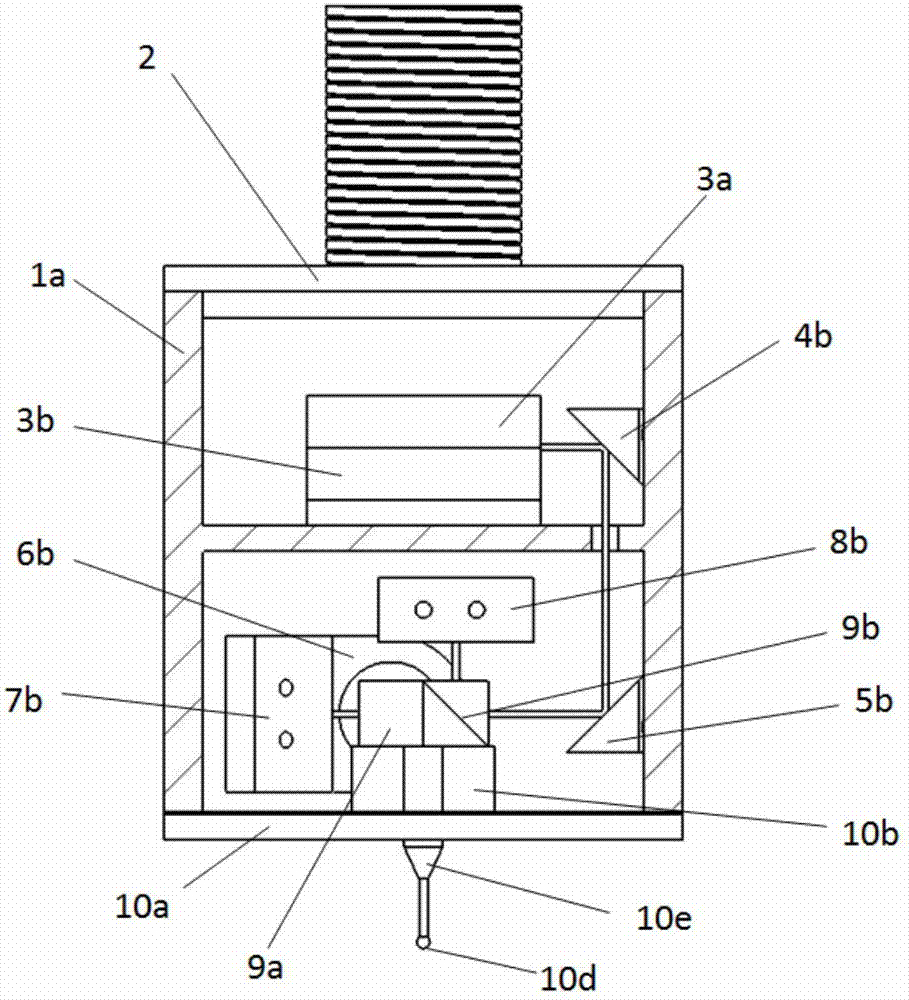

[0043] In this embodiment, the three-dimensional micro-nano trigger probe is composed of a probe unit and a measurement unit.

[0044] See figure 2 , image 3 , Figure 5 , Image 6 with Figure 7 , The probe unit is provided with a reed 10c in the shape of a "cross" on the ring seat 10a, Figure 8 The distal end of each cantilever of the reed 10c shown is formed integrally with the outer ring of the circular reed, and is fixedly connected to the circular base 10a by the outer ring of the circular reed; on the upper surface of the reed 10c, The center of the reed 10c is fixedly provided with a suspension sheet 10b in the shape of a "cross" to form a suspension structure of the suspension sheet 10b on the ring seat 10a; the upper end surface of the suspension sheet 10b is respectively fixedly provided with a first dichroic reflecting prism 9a and a second The spectroscopic reflection prism 9b and the wedge prism 9c are fixedly installed with a probe 10e in the central through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com