Lubricating oil nozzle flow two-CCD-camera measure system and method

A technology of binocular vision measurement and lubricating oil nozzles, which is applied in fixed measurement chambers, signal transmission systems, instruments, etc., can solve the problem of complex image processing algorithms in imaging systems, inability to directly output flow detection results, and unsuitability for multi-nozzle flow measurement Test and other issues to achieve the effect of reducing background signal interference, ensuring safety and health, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

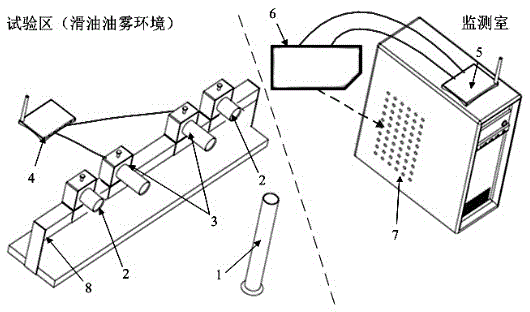

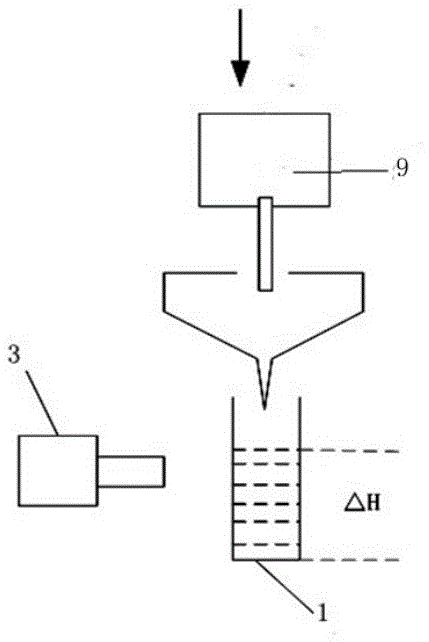

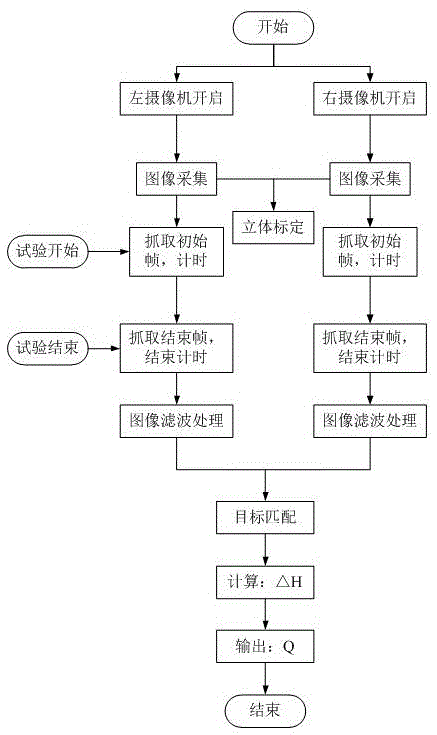

[0041] Such as figure 1 As shown, this embodiment provides a binocular visual measurement system for oil nozzle flow, including an imaging subsystem, an acquisition subsystem, and a processing subsystem connected in sequence; the imaging subsystem includes two light sources 2 that provide light sources for the imaging subsystem , two cameras 3; the acquisition subsystem includes a wireless image transmitter 4 for receiving camera 3 image signals, a wireless image receiver 5 for receiving signals of the wireless image transmitter 4 and a wireless image receiver 5 for sending The image acquisition card 6 for collecting image signals; the wireless image transmitter 4 is connected with the wireless image receiver 5 through wireless communication; the wireless image receiver 5 is connected with the image acquisition card 6; the processing subsystem includes processing the signal sent by the image acquisition card 6 The processing server 7; the server 7 includes image processing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com