Evanescent-wave type photoacoustic spectrum trace gas sensor based on optical fiber resonant cavity and measurement method

A technology of optical fiber resonator and photoacoustic spectroscopy, which is applied in the field of laser sensors to achieve the effect of improving detection sensitivity and increasing laser excitation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

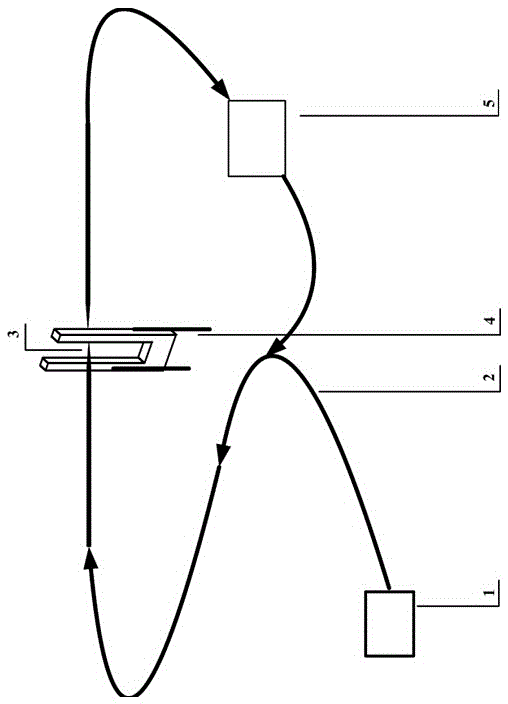

[0013] Specific implementation mode one: as figure 1 As shown, the optical fiber cavity-based evanescent photoacoustic spectrum trace gas sensor provided in this embodiment is composed of a semiconductor laser source 1, an optical fiber combiner 2, a tapered optical fiber 3, a quartz tuning fork 4, and a phase modulator 5. The tapered optical fiber 3 passes through the prongs of the quartz tuning fork 4, and the laser light emitted by the semiconductor laser source 1 is transmitted to the tapered optical fiber 3 through the fiber beam combiner 2, and the evanescence of strong energy is generated at the tapered optical fiber 3. At the same time, the phase modulator 5 enables the optical fiber combiner 2 to form an optical resonant cavity to further enhance the energy of the evanescent wave field. The gas to be measured absorbs the energy of the evanescent wave field to generate sound waves, and the quartz tuning fork 4 receives the sound wave signal. Inversion of gas concentrat...

specific Embodiment approach 2

[0022] Specific Embodiment 2: This embodiment provides a method for realizing trace gas concentration measurement using an evanescent photoacoustic spectrum trace gas sensor based on a fiber resonator, which is realized by the following steps:

[0023] Step 1. The laser light emitted by the semiconductor laser source 1 is input into the fiber combiner 2. After passing through the phase modulator 5, the fiber combiner forms an optical resonant cavity. The laser power in the fiber is amplified and enhanced, and then the tapered fiber is made 3 places Generate a strong optical evanescent field;

[0024] Step 2: The target gas to be measured absorbs the energy of the evanescent wave field at the tapered optical fiber to generate an acoustic wave field, and the quartz tuning fork 4 detects the acoustic wave signal to invert the gas concentration.

[0025] In this embodiment, the concentration of the target gas to be measured cannot be lower than the ppb level.

[0026] In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmission loss | aaaaa | aaaaa |

| Resonance frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com