Design method of power battery temperature control system and corresponding control system

A temperature control system and power battery technology, applied in battery/fuel cell control devices, secondary batteries, design optimization/simulation, etc., can solve the problems of high design and manufacturing costs, insulation, and high difficulty in cooling system manufacturing, and achieve practicality Strong, high reliability, flexible heating energy source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] The invention provides a method for designing a power battery temperature control system, which specifically includes the following steps:

[0036] (1) According to the installation layout structure of the power battery box and the layout of the battery modules inside the power battery box, construct a geometric model for the thermal simulation calculation of the power battery box;

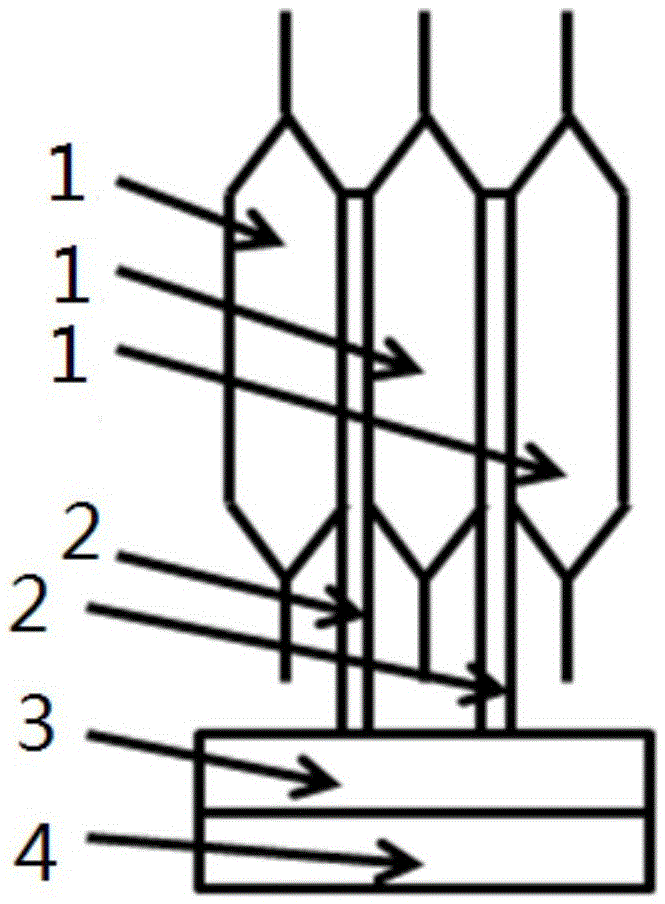

[0037] Among them, the geometric model of the thermal simulation calculation of the power battery box is as follows: figure 1 As shown, it includes a plurality of battery cells 1, a cooling plate 2, a heat conducting plate 3 and a heating device 4, the cooling plate 2 is arranged between adjacent battery cells 1, the heat conducting plate 3 is connected to the lower part of the cooling plate 2, and Connect with heating device 4 together.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com